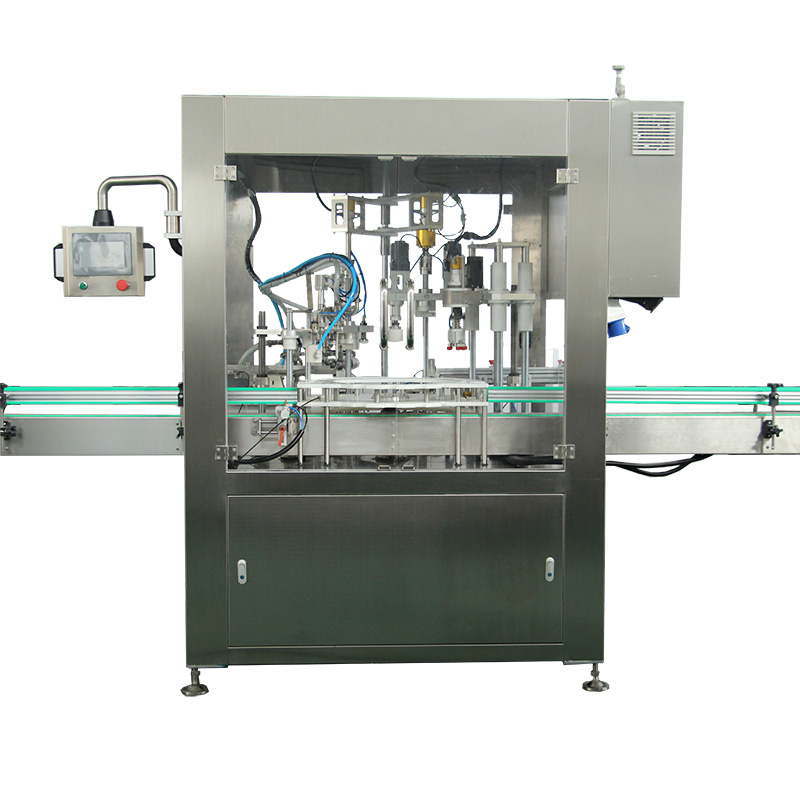

Αυτόματη μηχανή πλήρωσης και κάλυψης καλλυντικών τύπου σερβοεμβολοφόρου

Το μηχάνημα χρησιμοποιεί πλήρωση υψηλής ακρίβειας τύπου εμβόλου (Πώς λειτουργεί ένα πληρωτικό εμβόλου;), ειδικά σχεδιασμένο για την πλήρωση καλλυντικών υγρών, όπως κρέμες, λοσιόν κ.λπ.

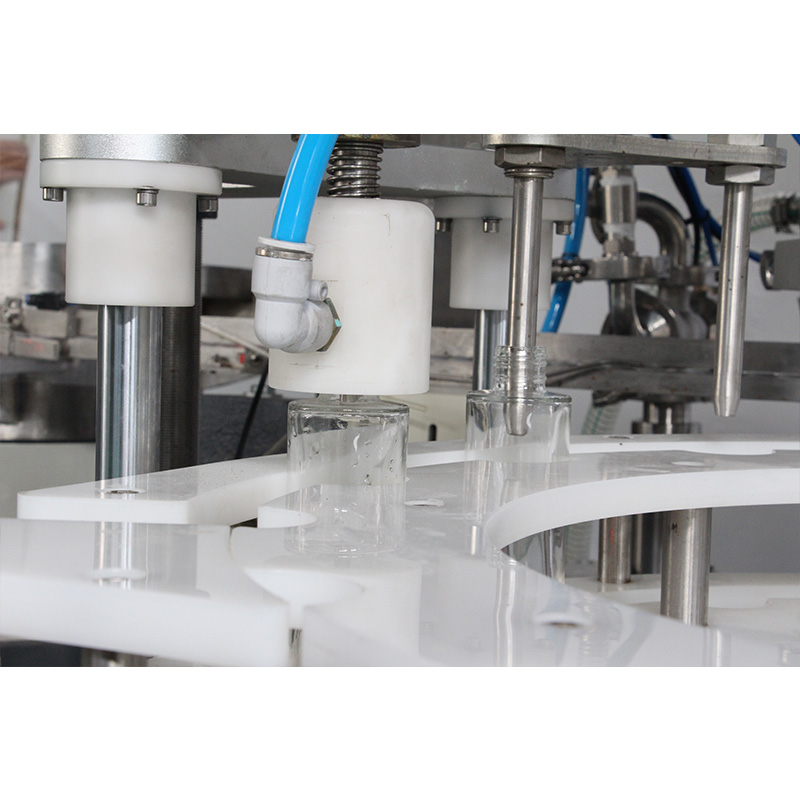

Αυτό το μηχάνημα διαθέτει διπλές αντλίες/ακροφύσια για να επιτυγχάνεται υψηλή ταχύτητα παραγωγής. Γεμίστε περισσότερο, πιο γρήγορα.

Ο φιλικός προς το χρήστη σχεδιασμός του προσφέρει στους χειριστές ευκολία στη λειτουργία και απαιτεί ελάχιστη συντήρηση για μεγαλύτερο χρόνο λειτουργίας. Μπορείτε να επιλέξετε ανάμεσα σε 2 ή 4 αντλίες/ακροφύσια για τοποθέτηση στο μηχάνημά σας.

Καλλυντικές κρέμες, τζελ μαλλιών, λοσιόν, οδοντόκρεμες, scrub ή λοσιόν σώματος· προσφέρουμε λύσεις για την αποθήκευση οποιουδήποτε είδους καλλυντικού προϊόντος σε οποιοδήποτε είδος δοχείου.

Τα μηχανήματά μας αποτελούν την ιδανική λύση για την πλήρωση καλλυντικών προϊόντων σε κανονικά αλλά και απαιτητικά σχήματα δοχείων. Τα μηχανήματα που προσφέρουμε για την πλήρωση καλλυντικών προϊόντων είναι εύκολα στον καθαρισμό, εύκαμπτα, γρήγορα και, πάνω απ' όλα, κατασκευασμένα από υλικά κατάλληλα για την επεξεργασία οποιουδήποτε είδους καλλυντικού προϊόντος. Από την πλήρωση, το πώμα και την επισήμανση: ο εξοπλισμός μας συνεχίζει να ανταποκρίνεται στις συνεχώς απαιτητικές ανάγκες της βιομηχανίας καλλυντικών και προσωπικής φροντίδας.

Περίληψη

1. Πλήρωση αντλίας εμβόλου σερβοκινητήρα υψηλής ακρίβειας, ακριβής μέτρηση, ρυθμιζόμενη, βολική συντήρηση, εύκολη λειτουργία, χωρίς φιάλη χωρίς πλήρωση, χωρίς φιάλη χωρίς βύσμα, χωρίς λειτουργία καλύμματος βύσματος.

2. Η μηχανή ΧΡΗΣΙΜΟΠΟΙΕΙ αυτόματο σύστημα συλλογής και τοποθέτησης καπακιού με προ-βίδωμα καπακιού

3. Χωρίς μπουκάλι, χωρίς γέμιση, χωρίς καπάκι, χωρίς κάλυμμα

4. Με διακόπτη επείγουσας διακοπής, αυτόματος συναγερμός όταν η μηχανή είναι εκτός λειτουργίας.

5. Αυτόματη διακοπή λειτουργίας όταν η πόρτα ασφαλείας είναι ανοιχτή

6. Αυτό το μηχάνημα με κάλυμμα σκόνης

Διαδικασία Λειτουργίας

1. Αυτόματο αποκωδικοποιητή μπουκαλιών: για επιλογή

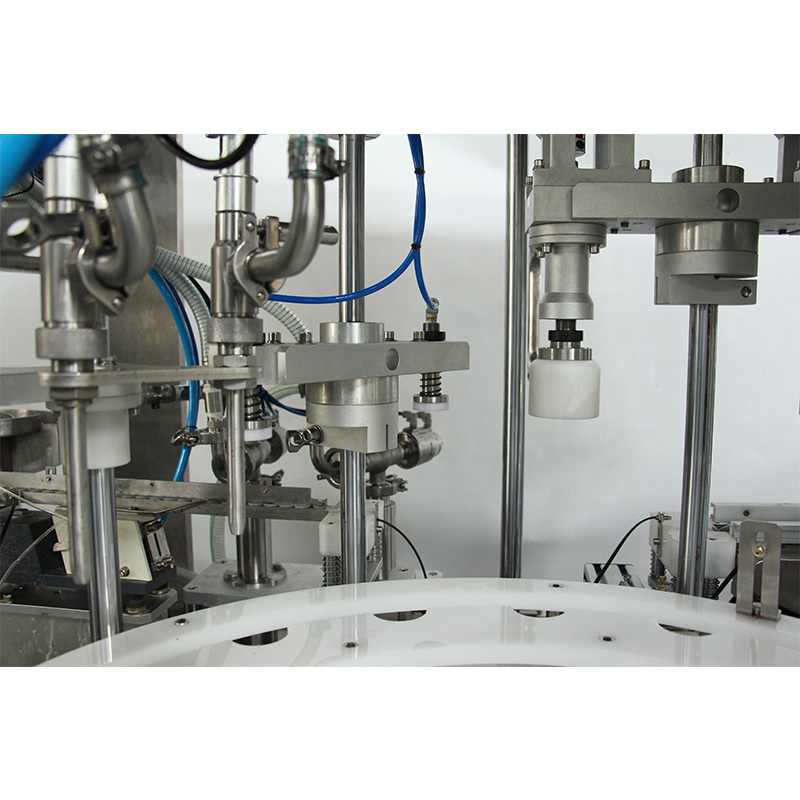

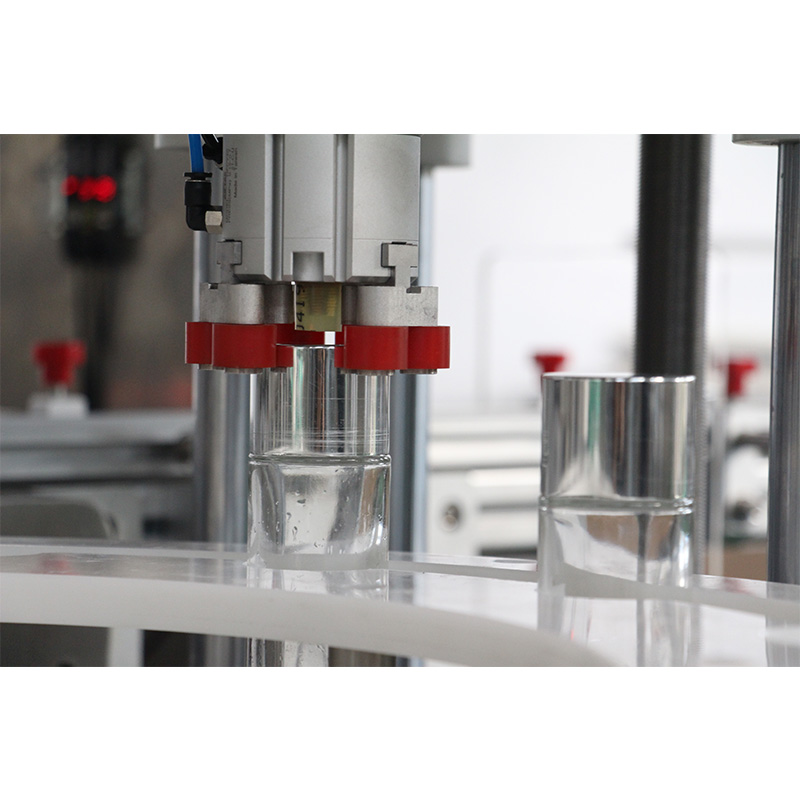

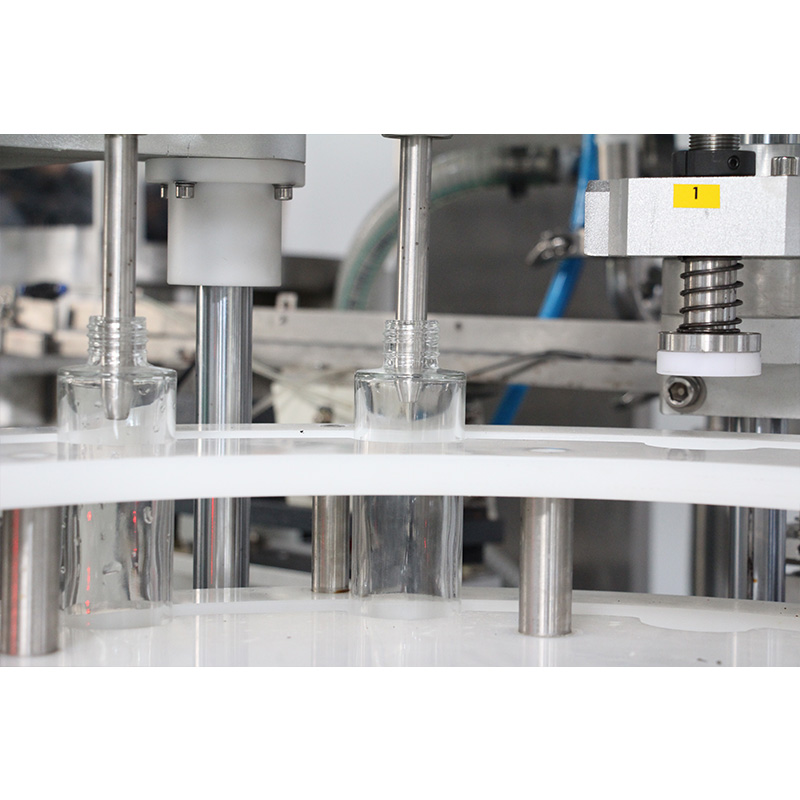

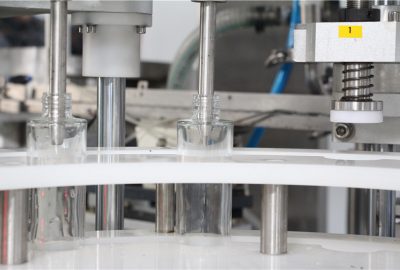

2. Πλήρωση: μεταφορά μπουκαλιών στον άσπρο τροχό αστεριού για πλήρωση, κάθε ακροφύσιο γεμίζει μέρος του συνολικού όγκου. Η πλήρωση είναι πλήρωση κατάδυσης και οδηγείται από σερβοκινητήρα

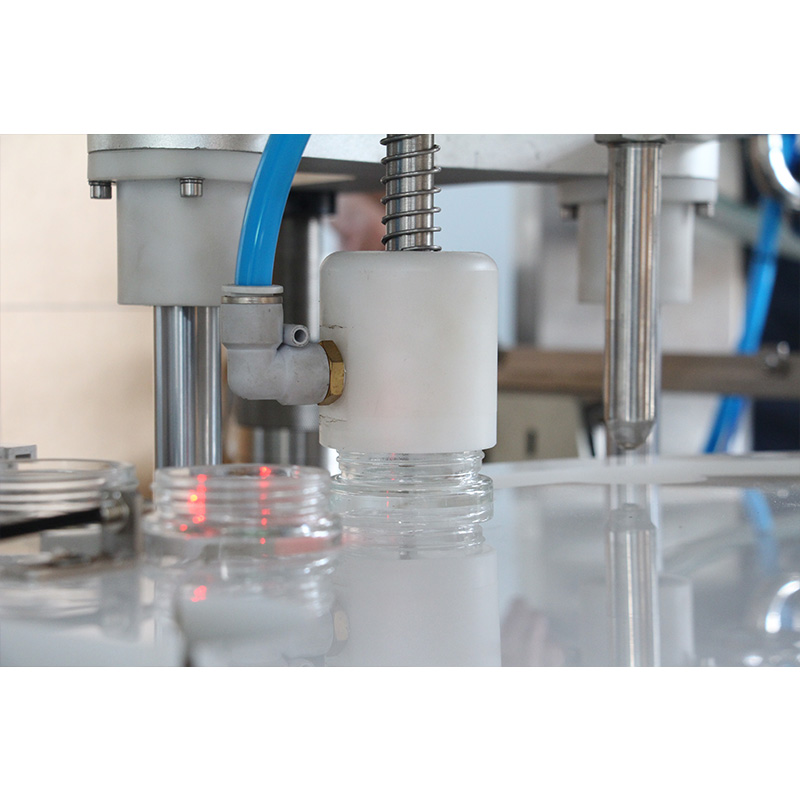

3. Επιλογή και τοποθέτηση με σύστημα προ-κάλυψης: τα καπάκια τροφοδοτούνται με χοάνη δόνησης στον σταθμό πώματος, στη συνέχεια επιλέγονται αυτόματα τα καπάκια και τοποθετούνται πάνω στο μπουκάλι και στη συνέχεια προ-κάλυψη.

4. Κάλυψη: η κάλυψη οδηγείται από τη σερβο μηχανή και η ροπή είναι διευθετήσιμη, κανένα σπάσιμο η ΚΑΠ με τη λογική ροπή

5. Μπουκάλια έξω: μεταφέρονται αυτόματα από το σύστημα μεταφορέων στη μηχανή ετικετών μετά το κλείσιμο.

Τεχνική παράμετρος

| Παραγωγική ικανότητα | 15-20 μπουκάλια/λεπτό |

| Εφαρμοσμένα μπουκάλια | Μπουκάλια 50ml/250ml |

| Ακροφύσιο πλήρωσης | 2 ακροφύσια |

| Ακρίβεια πλήρωσης | ±1% |

| Ακροφύσια κάλυψης | 1 ακροφύσιο |

| Σύστημα επιλογής και τοποθέτησης | 1 ακροφύσιο |

| Ποσοστό ανώτατου ορίου | 99.99% |

| Έλεγχος ταχύτητας | έλεγχος συχνότητας |

| Μέγεθος μπουκαλιού | Σύμφωνα με δείγματα |

| Το τροφοδοτικό | 220V 50Hz μονοφασικό |

| Εξουσία | 2,5kw |

| Παροχή αέρα | 0,3~04kfg/cm2 |

| Συνολικές διαστάσεις | 2000×1400×1900mm |

Κύρια διαμόρφωση

Μέσα, γύρω από τις πλευρικές πλάκες είναι από υψηλής ποιότητας ανοξείδωτο χάλυβα 304 ή άλλη έγκριση FDA για την παραγωγή υλικών, και τα μέρη επαφής υλικού είναι από ανοξείδωτο χάλυβα ποιότητας 316L.

| Αυτόματη μηχανή πλήρωσης σερβομηχανισμών | ||||

| Οχι. | Περιγραφές | ΜΑΡΚΑ | ΕΙΔΟΣ | Παρατήρηση (κατασκευασμένο στην Κίνα) |

| 1 | Σερβοκινητήρας | Panasonic | 0,45KW | Ιαπωνία |

| 2 | Περιστέλλων | Φενγκχουά | ATF1205-15 | Ταϊβάν |

| 3 | Κινητήρας μεταφορικού ιμάντα | ZhenYu | YZ2-8024 | Κίνα |

| 4 | σερβοκινητήρες | Panasonic | LXM 23DU15M3X | Ιαπωνία |

| 5 | Α.Ε. | Siemens | TM218LDALCODR4PHN | Γερμανός |

| 6 | Οθόνη αφής | Siemens | HMZGXU3500 | Γερμανός |

| 7 | Μετατροπέας συχνότητας | Ντάνφος | ATV12H075M2 | |

| 8 | Φωτογραφία ηλεκτρικού ρεύματος του μπουκαλιού Inspect | OPTEX ή ισότιμη μάρκα | BRF-N | Ιαπωνία |

| 9 | Πνευματικό Στοιχείο | Airtac | Ταϊβάν | |

| 10 | Περιστροφική βαλβίδα | F07/F05 | Δεν χρειάζεται λάδι | |

| 11 | Πνευματικός ενεργοποιητής | F07/F05 | Δεν χρειάζεται λάδι | |

| 12 | Συσκευή χαμηλής τάσης | Σνάιντερ | ΓΑΛΛΙΑ | |

| 13 | διακόπτης εγγύτητας | ΡΟΚΟ | SC1204-N | Ταϊβάν |

| 14 | Ρουλεμάν | Κίνα | ||

| 15 | Βίδα μολύβδου | Τραυματικό Τραύμα | Ταϊβάν | |

| 16 | Βαλβίδα πεταλούδας | CHZNA | Κίνα | |

Λεπτομερείς εικόνες

Η VKPAK κατασκευάζει και επισκευάζει κορυφαίας ποιότητας εξοπλισμό πλήρωσης υγρών από το 2008. Έχουμε ένα ευρύ φάσμα πελατών, συμπεριλαμβανομένων μερικών από τις μεγαλύτερες και πιο επιτυχημένες εταιρείες σε κλάδους όπως τα καλλυντικά, η επεξεργασία τροφίμων και η οίνος και τα ποτά. Πιστεύουμε στην ιδέα να παρέχουμε στους πελάτες μας τα καλύτερα προϊόντα στις πιο ανταγωνιστικές τιμές.

Η διαδικασία πλήρωσης για τα καλλυντικά δεν διαφέρει σχεδόν καθόλου από τα τρόφιμα και τα ποτά, δεδομένου ότι και τα δύο χρησιμοποιούν τους ίδιους τύπους μηχανημάτων για να επιτύχουν διαφορετικές συνεκτικότητες προϊόντων. Είναι απαραίτητο ο εξοπλισμός πλήρωσης καλλυντικών να επιτυγχάνει την κατάλληλη ποσότητα ανά δοχείο, ακόμη και αν η ουσία έχει τόσο παχύ όσο μια πάστα. Γι' αυτό σχεδιάζουμε κάθε μηχανή πλήρωσης καλλυντικών έχοντας κατά νου τις ποικίλες συνεκτικότητες προϊόντων.

Οι μηχανές πλήρωσης και πώματος καλλυντικών υγρών μας είναι ειδικά κατασκευασμένες για να καλύπτουν τις συνεχώς μεταβαλλόμενες απαιτήσεις της βιομηχανίας καλλυντικών. Προσπαθούμε συνεχώς να κάνουμε τον εξοπλισμό πλήρωσης καλλυντικών μας ικανό να προσαρμόζεται σε περισσότερα σχήματα και μεγέθη δοχείων. Στόχος μας είναι να κατασκευάζουμε τις καλύτερες μηχανές που είναι ικανές να χειρίζονται διάφορα επίπεδα ιξώδους.

Αν θέλετε να ξεκινήσετε τον σχεδιασμό και την εφαρμογή μηχανημάτων πλήρωσης καλλυντικών κατά παραγγελία (ενσωματωμένο ή συστήματα monoblock), μιλήστε με ένα από τα έμπειρα στελέχη της VKPAK. Μπορούμε να σας βοηθήσουμε να διασφαλίσετε ότι η γραμμή παραγωγής σας θα παρέχει χρόνια σταθερά υψηλής ποιότητας υπηρεσιών, με ελάχιστο κίνδυνο μηχανικών προβλημάτων ή βλαβών. Επικοινωνήστε μαζί μας σήμερα!