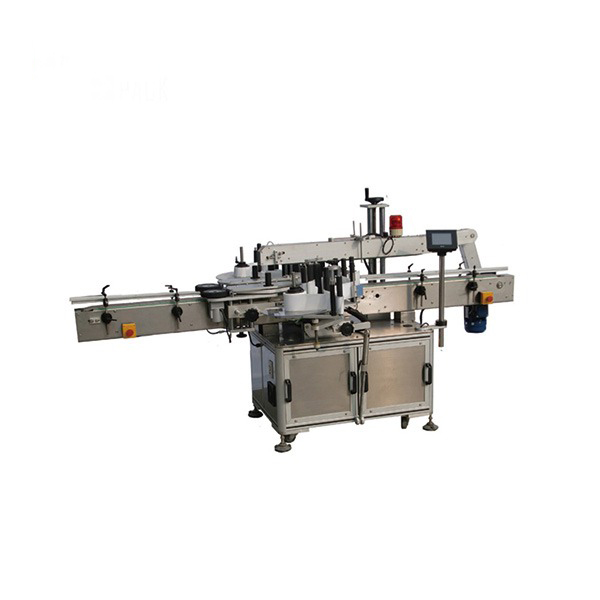

Automaattinen litteiden pullojen merkintäkone

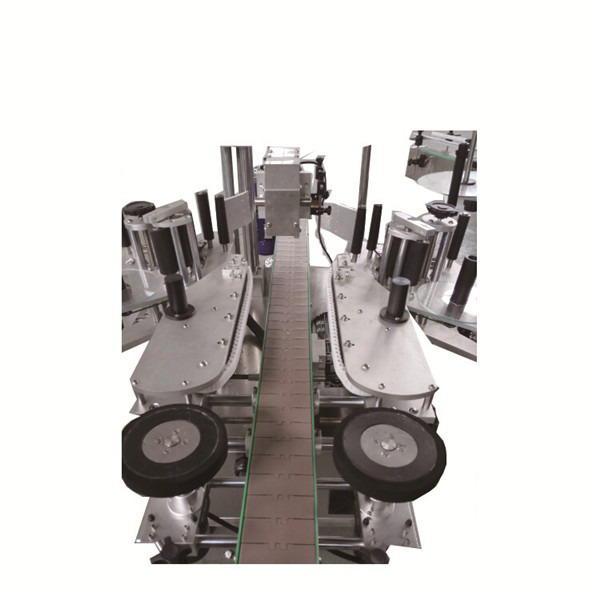

Tämä automaattinen litteiden pullojen etiketöintikone voi erottaa pullon, yksi moottori ohjaa puristuspullon laitetta ja kuljetinta, pullo liikkuu lineaarisesti kuljettimella. Servomoottori, PLC ja kosketusnäyttö takaavat korkean etiketöinnin.

Tämä automaattinen litteiden pullojen etiketöintikone voi erottaa pullon, yksi moottori ohjaa puristuspullon laitetta ja kuljetinta, pullo liikkuu lineaarisesti kuljettimella. Servomoottori, PLC ja kosketusnäyttö takaavat korkean etiketöinnin.

Automaattinen litteiden pullojen etiketöintikone on suunniteltu kahden sivun pohjalle litteitä ja neliönmuotoisia pulloja varten. Jotta voidaan täyttää joidenkin asiakkaiden vaatimukset sekä kaksipuolisten että pyöreiden pullojen etiketöinnille. Se on tarkoitettu lääkkeille, päivittäiskamikaaleille, elintarvikkeille, kulttuuritarvikkeille, elektroniikalle jne. Tämä kone ohjaa servomoottoria, PLC:tä ja kosketusnäyttöä, ja se on monitarra-/liimaetiketointikone.

Kuvaus

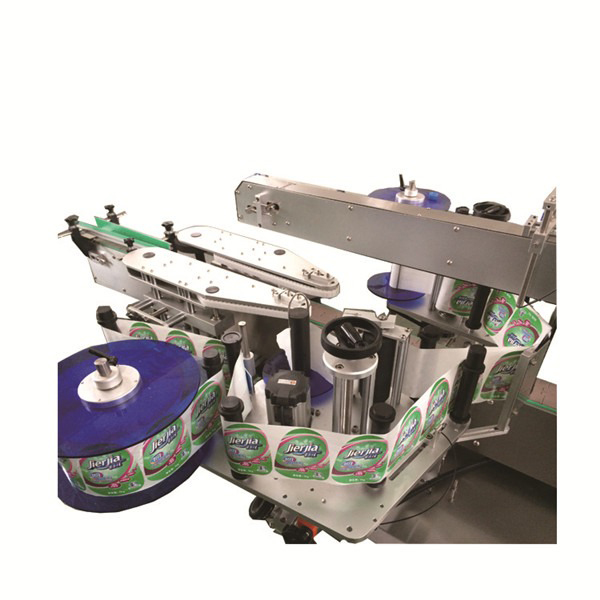

Litteiden tarrojen etiketöintikonetta käytetään litteiden säiliöiden yhden puolen etiketöintiin tai kokonaan tai osittain käärittyjen etikettien kiinnittämiseen erikokoisiin säiliöihin. Tässä kestävässä koneessa on sileä ruostumattomasta teräksestä valmistettu pinta, joka kattaa myös päärungon. Se on käyttäjäystävällisin laite, jonka kapasiteetti on 30–350 yksikköä minuutissa tuotteen ja etiketin koosta riippuen. Nopeus riippuu myös säiliön vakaasta liikkeestä koneen kuljettimella suurella nopeudella. Tässä hienostuneessa ja yksinkertaisessa mallissa on uusin hihnavälityslaite, jonka ansiosta osia ei tarvitse vaihtaa, vaikka säiliöiden ja etikettien koko muuttuisi. Lisäksi koneessa on edistyksellinen ja selkeä yhden pisteen ohjausjärjestelmä online-nopeuden vaihteluun. Lisäksi tämä monipuolinen ja tarkka laite tunnetaan korkeasta etikettien sijoittelutarkkuudestaan. Siinä on myös integroitu AC-taajuusmuuttajajärjestelmä.

Pakkaustyyppi: Pullot

Pakkausmateriaali: Metalli

Tyyppi: Merkintäkone, Merkintäkone

Kunto: Uusi

Myynnin jälkeinen palvelu: Online-tuki, videotekninen tuki, ilmaiset varaosat, kenttäasennus, käyttöönotto ja koulutus

Alkuperämaa: Shanghai, Kiina

Tuotemerkki: VKPAK

Jännite: 220 V 50/60 Hz

Sovellus: Vaatteet, juomat, kemikaalit, elintarvikkeet, lääketieteellinen

Paino: 200 kg

Automaattinen luokka: Automaattinen

Käyttötyyppi: Mekaaninen

Mitat (P * L * K): 1800 mm * 1000 mm * 1300 mm

Toiminto: tarra pullossa

Merkintänopeus: 20–100 pulloa /min

Moottori: servomoottori

Koneen nimi: etikettien kiinnityskone

Materiaali: Ruostumaton teräs

takuu: 1 vuosi

Merkintätarkkuus: 1 mm

Palvelu: Tekninen tuki 24/7

pakkaus: Pitkän matkan puinen kotelo

Tekninen parametri

| Nimi | Automaattinen litteiden pullojen merkintäkone |

| Merkintänopeus | 60-350 kpl/min (riippuen etiketin pituudesta ja pullon paksuudesta) |

| Kohteen korkeus | 30–350 mm |

| Kohteen paksuus | 20–120 mm |

| Tarran korkeus | 15–140 mm |

| Tarran pituus | 25–300 mm |

| Etikettirullan sisähalkaisija | 76 mm |

| Etikettirullan ulkohalkaisija | 420 mm |

| Merkintöjen tarkkuus | ±1 mm |

| Virtalähde | 220 V 50/60 Hz 3,5 kW yksivaiheinen |

| Tulostimen kaasunkulutus | 5 kg/cm² |

| Merkintäkoneen koko | 2800 (P) × 1650 (L) × 1500 (K) mm |

| Merkintäkoneen paino | 450 kg |

Tärkeimmät ominaisuudet:

- PLC ja kosketusnäyttö, servomoottori

- Varustettu varoituslaitteella, joka ilmoittaa riittämättömistä tai rikkoutuneista tarroista

- Ei pulloa, ei etikettiä

- Ei etikettejä, ei merkintöjä ja automaattisia varoituksia

- Ei nauhaa, automaattinen varoitus

- Servomoottorin ohjaus, vakaa merkintä.

- Tarratunnistin ja sähköosat on valmistettu Japanissa

- Sopii pyöreisiin/litteisiin/neliömäisiin pulloihin

Kone pystyy käyttämään etikettejä, joiden vähimmäispituus on 12 mm ja korkeus 8 mm:stä 70/90/120/150 mm:iin. Rullan halkaisija on yleensä 300 mm ja ytimen halkaisija 75 mm. Kahden etiketin välinen rako on noin 3 mm. Lisäksi siinä on sisäänrakennettu automaattinen etiketin pituuden tunnistusjärjestelmä, joka poistaa etiketin pituuden manuaalisen syöttämisen ja tallentamisen muistiin sekä samojen tietojen hakemisen, kun etiketin kokoa muutetaan ja kone käynnistetään uudelleen. Tämä moderni järjestelmä säästää kokonaiskustannuksia ja arvokasta aikaa, välttää koneen seisokkiajat ja mahdollistaa korkeamman tuottavuuden. Tämä malli on saatavana lisävarusteena saatavalla tukevalla lasisella tai akryylisellä suojakaapilla. Itse asiassa se täyttää kaikki nykymarkkinoilla tyypillisen koneen perustarpeet.