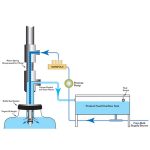

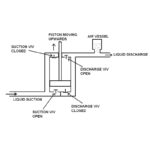

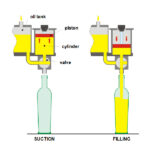

מילוי כבידה הוא שיטת המילוי הפשוטה ביותר. המבנה והתפעול הפשוטים של מכונות מילוי כבידה מאפשרים להן לפעול עם מינימום תחזוקה. מיכל האספקה (הנקרא ליתר דיוק קערת המילוי) הוא החלק העליון והמרכזי של המכונה. גבעולי מילוי מחוברים למשטח התחתון של הקערה בכל נקודת מילוי של המיכל. צינור אוורור משתרע כלפי מעלה לתוך קערת המילוי עד לנקודה מעל מפלס הנוזל. כדי להתחיל את פעולת המילוי, המיכל מורם על ידי הפלטפורמה עד שהוא נוגע בגבעול המילוי. לאחר מכן, הפלטפורמה ממשיכה להרים את המיכל כנגד הגבעול, ופותחת את שסתום המילוי. כאשר שסתום המילוי פתוח, הנוזל מתנקז לתוך המיכל. האוויר במיכל זורם החוצה דרך צינור האוורור אל החלל שמעל הנוזל בקערת המילוי. למרות שהמיכל מתמלא, הנוזל ממשיך לזרום פנימה. הנוזל העודף עולה בצינור האוורור עד שהוא מגיע לאותו גובה כמו מפלס הנוזל בקערה. מכיוון שצינור האוורור משתרע מעל מפלס הנוזל של הקערה, אין גלישה של נוזל מהמיכל אל תוך הקערה.

עקרון מילוי הכבידה

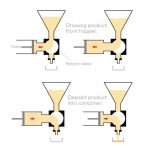

איך זה עובד:

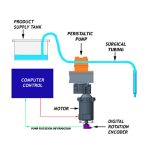

אספקת המוצר בתפזורת נשאבת לתוך מיכל אחסון מעל סט של שסתומים המופעלים באופן פנאומטי. כל שסתום מתוזמן באופן עצמאי על ידי המחשב הראשי של המילוי כך שכמויות מדויקות של נוזל יזרמו באמצעות כוח הכבידה לתוך המיכל. מילויי כבידה הבנויים עם יכולת מילוי מלמטה למעלה יכולים להתמודד עם מגוון רחב של נוזלים זרימים, כולל מוצרים מוקצפים.

בַּקָשָׁה:

סוג זה של מילוי מתאים ביותר לנוזלים בעלי צמיגות דקה מאוד שאינה משתנה עם טמפרטורת הסביבה או עם שינויים באצווה. מכונה זו מתאימה גם ליישומים בהם מחזור הנוזל בנתיב הנוזל אינו רצוי. למרות שסוג זה של מילוי משמש בעיקר על מוצרים שאינם מקציפים, הקצף עשוי להיות מוגבל ומבוקר על ידי יכולת מילוי מתחת לפני השטח/מלמטה למעלה.

דוגמאות:

מים, ממסים, אלכוהול, כימיקלים מיוחדים, צבע, דיו, כימיקלים קורוזיביים כגון חומצות ואקונומיקה.

יתרונות:

זהו סוג מכונת המילוי החסכונית ביותר עבור מגוון מוגבל של יישומים. הוא מתאים במיוחד לכימיקלים קורוזיביים.

מכונת מילוי בקבוקים כימיים אוטומטית בכוח משיכה VK-GF

קרא עוד

כאשר המוצר מגיע לצינור האוורור, העודף חוזר למיכל המוצר. מחזור המילוי הכבידה מבוקר בזמן וניתן להתאמה מלאה. לאחר השלמת המחזור, ראש המילוי עולה, שסתומי המילוי נסגרים ומובילי הצוואר נסוגים. לבסוף, השער הקדמי הפנאומטי משתחרר ומאפשר למיכלים המלאים לצאת. מפלס המוצר במיכל מנוהל על ידי חיישנים השולטים במשאבה שתשאוב את המוצר למיכל מהאספקה שלך.

אם המוצר מוקצף, הקצף יעלה בצינור האוורור מעל גובה הנוזל בקערה. אם מדובר בקצף יציב ולא יתפרק, הוא בסופו של דבר יעלה על גדותיו לתוך הקערה. מסיבה זו, חומרי מילוי כבידה אינם משמשים לעתים קרובות למוצרים מוקצפים. בזמן שנקבע מראש לאחר מילוי המיכל, הוא יורד ממצב המילוי שלו, וסוגר את שסתום המילוי. הנוזל שנותר בגזע המילוי מוסר מצינור האוורור בכמה דרכים.

מילוי כבידה

בעוד שמכונות מילוי בגלישה יאפשרו לאורז למלא עד לרמה מסוימת, מכונות מילוי בכוח משיכה מאפשרות לאורז למלא כל בקבוק באותו נפח של מוצר באמצעות עקרון מילוי מבוסס זמן. שוב, בהתייחס לפערים בנפח הפנימי של מיכלים, מכונות מילוי בכוח משיכה יבטיחו שכל בקבוק יכיל את אותה כמות של מוצר, גם אם הדבר יגרום לכך שחלק מהמיכלים נראים מלאים יותר או פחות מלאים מאחרים.

בעוד שמכונות מילוי כבידה יכולות להשתמש במספר פיות שונות, באופן כללי הפיות ייפתחו למשך זמן מוגדר מראש כדי לאפשר למוצר לזרום מהמיכל אל הבקבוקים או המיכלים הממתינים. ברוב המכונות, ניתן לכוונן את זמן המילוי עבור כל ראש או פיה בנפרד כדי לאפשר דיוק רב יותר. ניתן גם לכוון את הזמנים לשברירי שנייה כדי לשפר גם את הדיוק הנפחי. לאחר שהזמן שנקבע מראש הושג, הפיות יפסיקו את זרימת המוצר. עבור מכונות חצי אוטומטיות, משתמשים במתגים פשוטים המופעלים על ידי המפעיל כדי להפעיל את המחזור, בעוד שמכונות אוטומטיות ישתמשו בבקר בקרה (PLC) כדי להשיג זאת.

הבחירה להשתמש במערכת מילוי לפי רמה או במערכת מילוי לפי נפח תמיד תלויה במאפייני הפרויקט הייחודי הנדון. עבור אורזים המשתמשים במיכלים שקופים, המגמה היא לעקרון הגלישה, המאפשר עלייה במראה המדף ובערך האסתטי כתוצאה מהמילויים המפלסים. עבור אורזים שאינם משתמשים במיכלים אטומים, מילוי כבידה עשוי להציע אלטרנטיבה טובה יותר, במיוחד כאשר נפחים עקביים חשובים לתעשייה. אך אפילו חריגים לכללים אלה עשויים לחול כאשר המיכלים או המוצר עצמם ייחודיים. העצה הטובה ביותר לאורז חדש היא לא רק להכיר, אלא גם להבין, את האפשרויות השונות הזמינות לאריזת המוצר הייחודי שלכם לפני בחירת כל מכונת אריזה.