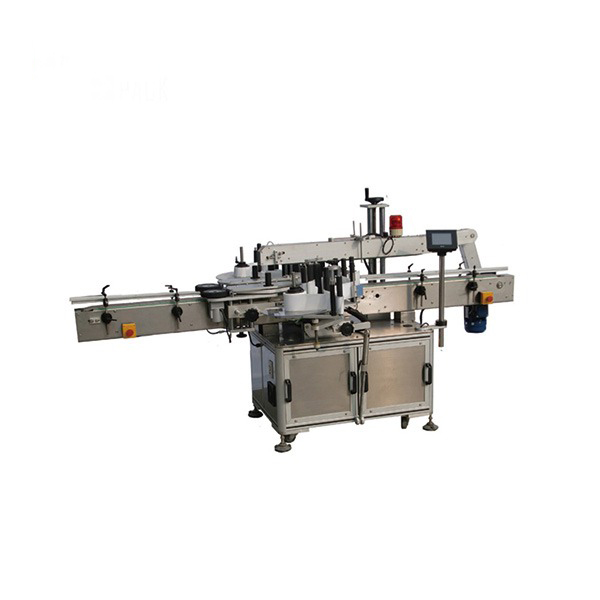

Mesin Pelabelan Botol Datar Otomatis

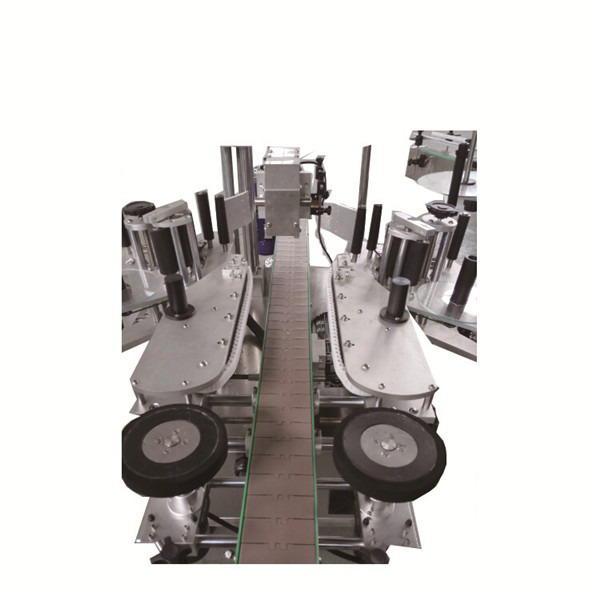

Mesin Pelabelan Botol Pipih Otomatis ini dapat memisahkan botol. Satu motor penggerak mengendalikan perangkat pengepres botol dan konveyor. Botol akan bergerak linier di atas konveyor. Motor servo, PLC, dan layar sentuh akan memberikan label yang tinggi.

Mesin Pelabelan Botol Pipih Otomatis ini dapat memisahkan botol. Satu motor penggerak mengendalikan perangkat pengepres botol dan konveyor. Botol akan bergerak linier di atas konveyor. Motor servo, PLC, dan layar sentuh akan memberikan label yang tinggi.

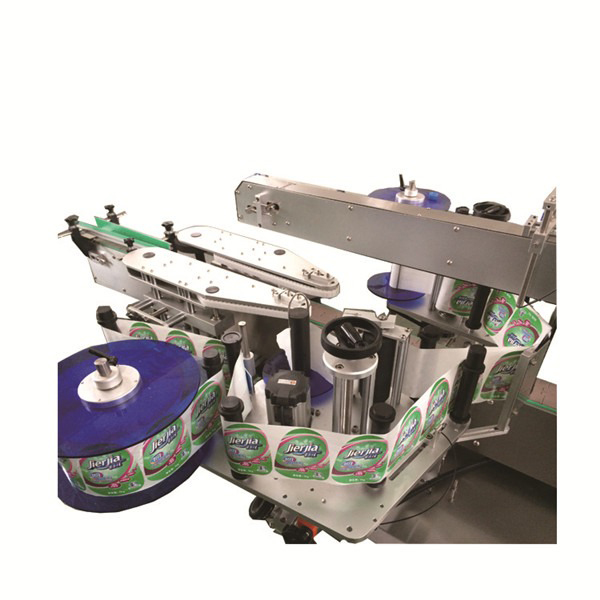

Mesin Pelabelan Botol Pipih Otomatis dirancang dengan alas dua sisi untuk botol pipih dan botol persegi. Mesin ini dirancang untuk memenuhi kebutuhan label dua sisi dan botol bundar bagi sebagian pelanggan. Mesin ini dapat digunakan untuk obat-obatan, bahan kimia sehari-hari, perlengkapan kultur makanan, elektronik, dan lain-lain. Mesin ini dikendalikan oleh motor servo, PLC, dan layar sentuh. Mesin ini merupakan mesin pelabelan multi-stiker/perekat.

Keterangan

Mesin pelabelan stiker datar digunakan untuk memberi label pada satu sisi wadah datar; atau label yang membungkus seluruh dan sebagian pada berbagai dimensi wadah lainnya. Mesin yang tangguh ini memiliki lapisan baja tahan karat yang halus, yang juga mencakup rangka utama. Ini adalah peralatan yang paling mudah digunakan, dengan kapasitas pelabelan 30 hingga 350 unit per menit; sesuai ukuran produk dan label. Kecepatannya juga tergantung pada pergerakan wadah yang stabil pada konveyor mesin dengan kecepatan yang lebih tinggi. Model yang canggih dan sederhana ini memiliki perangkat jarak sabuk terbaru yang menghasilkan sistem tanpa penggantian bagian, bahkan jika ukuran wadah dan label diubah. Selain itu, mesin ini mencakup sistem kontrol titik tunggal yang canggih dan unik untuk variasi kecepatan online. Lebih lanjut, peralatan yang serbaguna dan presisi ini terkenal karena akurasi penempatan labelnya yang tinggi. Ini juga menggabungkan sistem penggerak frekuensi AC terintegrasi.

Jenis Kemasan: Botol

Bahan Kemasan: Logam

Tipe: Mesin Pelabelan, Mesin Pelabelan

Kondisi: Baru

Layanan Purna Jual yang Disediakan: Dukungan online, Dukungan teknis video, Suku Cadang Gratis, Instalasi lapangan, komisioning, dan pelatihan

Tempat Asal: Shanghai, Tiongkok

Nama Merek: VKPAK

Tegangan: 220V 50/60HZ

Aplikasi: Pakaian, Minuman, Kimia, Makanan, Medis

Berat: 200kg

Kelas Otomatis: Otomatis

Tipe Penggerak: Mekanik

Dimensi (P*L*T): 1800mm*1000mm*1300mm

Fungsi: label stiker pada botol

Kecepatan pelabelan: 20-100 botol / menit

Motor: motor servo

Nama mesin: mesin pelabel

Bahan: Baja Tahan Karat

garansi: 1 tahun

akurasi pelabelan: 1mm

Layanan: Dukungan Teknis 24/7

pengepakan: Kotak Kayu Jarak Jauh

Parameter Teknis

| Nama | Mesin Pelabelan Botol Datar Otomatis |

| Kecepatan Pelabelan | 60-350 pcs/menit (Tergantung panjang label dan ketebalan botol) |

| Tinggi Objek | 30-350 mm |

| Ketebalan Objek | 20-120 mm |

| Tinggi Label | 15-140mm |

| Panjang Label | 25-300mm |

| Diameter Dalam Rol Label | 76 mm |

| Diameter Luar Rol Label | 420 mm |

| Akurasi Pelabelan | ±1 mm |

| Catu Daya | 220V 50/60HZ 3,5KW Fase tunggal |

| Konsumsi Gas Printer | 5 kg/cm^2 |

| Ukuran Mesin Pelabelan | 2800(P)×1650(L)×1500(T)mm |

| Berat Mesin Pelabelan | 450 kg |

Fitur Utama:

- PLC dan layar sentuh, motor servo

- Dilengkapi dengan alat peringatan label tidak mencukupi, label rusak

- Tidak ada botol, tidak ada label

- Tidak ada label, tidak ada pelabelan dan peringatan otomatis

- Tidak ada pita, peringatan otomatis

- Kontrol motor servo, pelabelan stabil.

- Sensor label dan komponen listrik dibuat di Jepang

- Cocok untuk botol bulat / datar / persegi

Mesin ini dapat menggunakan label dengan panjang minimal 12 mm dan tinggi berkisar antara 8 mm hingga 70/90/120/150 mm. Biasanya, diameter rol adalah 300 mm dan diameter inti adalah 75 mm. Celah antara kedua label sekitar 3 mm. Selain itu, mesin ini memiliki sistem deteksi panjang label otomatis bawaan yang menghilangkan proses memasukkan dan menyimpan detail panjang label secara manual ke dalam memori dan mengambil data yang sama ketika ukuran label diubah dan mesin dihidupkan ulang. Sistem modern ini menghemat biaya keseluruhan, waktu yang berharga, menghindari waktu henti mesin, dan memungkinkan pencapaian produktivitas yang lebih tinggi. Model ini tersedia dengan lemari pengaman kaca atau akrilik yang kokoh opsional. Sebenarnya, mesin ini memenuhi semua kebutuhan dasar mesin pada umumnya yang dibutuhkan di pasaran saat ini.