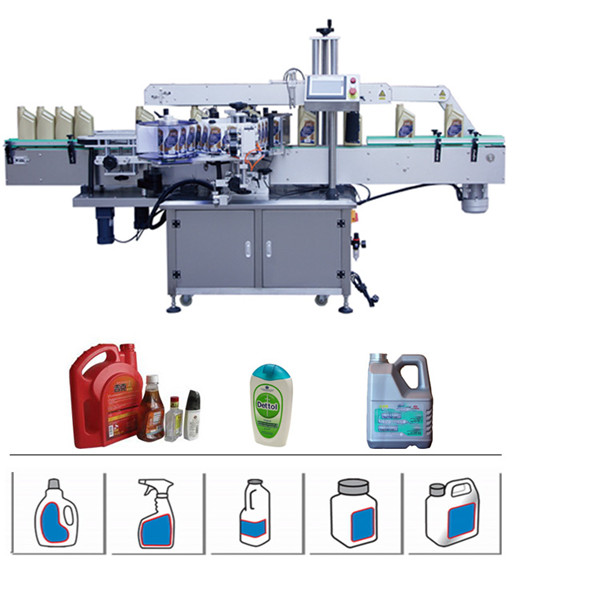

Automatinis lipnus butelių etikečių klijavimo aparatas

Automatinis lipnus butelių etikečių klijavimo aparatas tinka daugeliui butelių etikečių klijavimo. Etiketę klijuojant butelis automatiškai pasisuka, kad etikečių klijavimo įtaisas galėtų daryti spaudimą etiketėms klijuoti.

Automatinis lipnus butelių etikečių klijavimo aparatas tinka daugeliui butelių etikečių klijavimo. Etiketę klijuojant butelis automatiškai pasisuka, kad etikečių klijavimo įtaisas galėtų daryti spaudimą etiketėms klijuoti.

Tinka medicinos, maisto, gėrimų ir chemijos pramonei. Gali būti naudojamas plastikinėms, stiklinėms, metalinėms ir kitoms apvalioms talpykloms / buteliams. Dėl novatoriško dizaino jo valdymas yra toks paprastas, kad juo gali naudotis net paprastas žmogus.

Aprašymas

Iš esmės etikečių klijavimo mašina naudojama automatiškai klijuoti etiketes ant produktų, talpyklų, butelių ir kt. Rankinis ženklinimas gali būti daug laiko ir neprofesionalus produkto pakavimo būdas. Seniai, kai nebuvo išrastos ženklinimo mašinos, butelių, stiklainių, talpyklų ir kt. ženklinimas buvo atliekamas rankiniu būdu, o tai buvo ilgas ir daug laiko reikalaujantis procesas. Tačiau dabar ženklinimo mašinos tapo pramonės palaima. Kalbant apie produktų pakuotes dideliais kiekiais, nėra kito būdo ženklinti produktus, išskyrus ženklinimo mašinos naudojimą. Taigi, ženklinimo mašina naudojama daugelio pramonės šakų, tokių kaip farmacija, kosmetika, plataus vartojimo prekės (FMCG), maistas ir gėrimai ir kt., pakavimo procese.

Pakuotės tipas: Buteliai

Pakavimo medžiaga: popierius

Tipas: Etikečių klijavimo mašina, Etikečių klijavimo mašina

Būklė: Nauja

Teikiamos garantinio aptarnavimo paslaugos: internetinė pagalba, vaizdo įrašų techninė pagalba, nemokamos atsarginės dalys, įrengimas, paleidimas ir mokymai lauke, inžinieriai, galintys aptarnauti mašinas užsienyje.

Kilmės vieta: Šanchajus, Kinija

Prekės ženklas: VKPAK

Įtampa: 220 V 50/60 Hz

Taikymas: gėrimai, chemija, maistas, medicina

Automatinis įvertinimas: Automatinis

Sertifikavimas: ISO9001

Varomasis tipas: Mechaninis

Matmenys (I * P * A): 1800 mm * 1000 mm * 1300 mm

Funkcija: lipdukas ant butelio

Ženklinimo greitis: 20–100 butelių/min.

Variklis: servo variklis

Medžiaga: Nerūdijantis plienas

garantija: 1 metai

ženklinimo tikslumas: 1 mm

Aptarnavimas: Techninė pagalba visą parą

Pakuotė: Medinis dėklas dideliems atstumams

Techninis parametras

| Modelis / techniniai parametrai | VK-DSL |

| Ženklinimo greitis (vnt./min.) | 40–100 (priklauso nuo medžiagos ir etiketės dydžio) |

| Ženklinimo tikslumas (mm) | ±1,0 mm (medžiagos ir etikečių dydžiai neįskaičiuojami) |

| Etiketės dydis (mm) | (I) 20–280 mm (A) 30–144 mm |

| Medžiagos dydis (mm) | Φ20–φ100 mm (aukštis) 40–200 mm |

| Ritinio vidinis ilgis (mm) | φ76 mm |

| Ritinio išorinis skersmuo (mm) | Maks.: Φ350 mm |

| Mašinos dydis (mm) | (I) 2000 * (P) 850 * (A) 1450 (mm) |

| Maitinimo šaltinis | 220 V kintamoji srovė, 50 Hz / 60 Hz, 1500 W |

- Stabiliai prisitaikantis „Siemens PLC“ valdymas ir „Panasonic“ servovariklis užtikrina stabilų mašinos darbą ir tikslų etikečių spausdinimą. Tai didelis našumas ir efektyvumas.

- Paprastas valdymas – jutiklinis ekranas gali būti anglų, ispanų, prancūzų, rusų ir bet kuria kita kalba. Jį lengva valdyti ir galima prijungti prie kitų gamybos pakavimo linijos mašinų.

- Didelis tikslumas – tikslumas nuo +/- 0,5–1 mm. Platus taikymo diapazonas – plačiai naudojamas buteliams, kurių skersmuo yra nuo 25 mm iki 120 mm, o aukštis – nuo 25 mm iki 300 mm. Jei pageidaujate individualaus aukščio nuo 10 mm iki 150 mm, o ilgio – nuo 15 mm iki 300 mm, prašome kreiptis į mus.

- Didelis greitis – maksimalus greitis gali siekti 150 butelių per minutę, priklausomai nuo etiketės ir butelio dydžio.

- Europos standartas – ženklinimo mašina pagaminta pagal CE standartą, Taivano technologiją.

Detalūs vaizdai

Butelių ženklinimo mašinos darbo procesas

- Rankiniu būdu dėkite butelius ant konvejerio arba naudokite automatinį butelių sukimo stalą

Buteliai bus atskirti butelių separatoriumi, kad kiekvienas butelis būtų atstumtas, siekiant užtikrinti stabilų veikimą - Visus veiksmus valdo PLC, automatiškai aptinka butelį ir etiketes, automatiškai klijuoja etiketes ant abiejų butelių pusių. Mašina turi funkciją, nėra butelio, nėra etikečių, automatinis įspėjimas, jei nėra etiketės arba jos trūksta.

- Užklijavus etiketes ant butelių, etikečių klijavimo įrenginys įklijuos etiketes, kad pritvirtintų etiketę prie butelių.

- Tada butelis pereina prie kito apdorojimo.

Pagrindinės savybės:

- Priima žingsninį servo variklį, PLC valdymo sistemą, spalvotą jutiklinį ekraną.

- Priimkite Japonijos foto jutiklį, kad automatiškai aptiktų ir patikrintų etikečių ilgį

- Įrengtas įspėjamasis įtaisas apie nepakankamus etikečių kiekius, pažeistas etiketes ir chromatinių juostų nebuvimą.

- Tikslus etikečių išdėstymas, didelis greitis ir didelis ženklinimo tikslumas.

- Automatinis aptikimas, nėra konteinerio, nėra ženklinimo.

- Mašinos korpusas pagamintas iš nerūdijančio plieno, visiškai atitinka GMP reikalavimus

- Galima įdiegti su kodavimo / rašaliniu spausdintuvu (neprivaloma).

Lipnių lipdukų klijavimo mašina yra visiškai automatizuota, vertikali ir linijinė. Šis kelių pakuočių modelis pasižymi daugybe patogių naudoti funkcijų. Tai tinkamiausia įranga priekinėms, galinėms ar šoninėms etiketėms klijuoti ant plokščių, ovalių, kvadratinių ir apvalių formų talpyklų. Ši tvirta mašina gali atspausdinti iki 100 etikečių per minutę, priklausomai nuo gaminių formos ir dydžio bei etiketės dydžio. Ji taip pat turi automatinę ir sinchronizuotą sistemą, skirtą gaminiui sulygiuoti su viršutine laikymo diržo sistema. Kitas puikus šios įrangos elementas yra pažangi mikroprocesoriaus valdoma etikečių išdavimo sistema su naujausia etikečių ir gaminių jutimo sistema. Ši daugiafunkcė, didelės spartos etikečių klijavimo mašina yra efektyvi, tiksli ir ilgaamžė. Ji sukurta taip, kad atitiktų įvairius šiuolaikinių pakavimo linijų naudotojų reikalavimus. Šiai paprastai valdomai ir lengvai reguliuojamai mašinai reikia minimalių įrankių ir dalių keitimo. Ji gali būti specialiai suprojektuota su padavimo sliekų ir kišenių sistema, kad būtų užtikrintas tinkamas butelių sulygiavimas ant konvejerio, siekiant tiksliai ženklinti. Šis modelis netgi turi išskirtinę vieno taško sinchronizuotą greičio valdymo sistemą. Be to, integruota ir iš anksto nustatyta etiketės ilgio aptikimo sistema leidžia išvengti rankinio etiketės ilgio duomenų tiekimo ir saugojimo atmintyje bei šių duomenų atkūrimo kiekvieną kartą, norint pakeisti etiketės dydį ir paleisti įrangą iš naujo. Tai taupo jūsų laiką, apsaugo nuo mašinos prastovų ir padidina našumą. Taip pat galima įsigyti su pasirenkama apsaugine spintele, pagaminta iš tvirto stiklo arba akrilo. Ši įranga gali būti specialiai sukurta vienpusėms etiketėms klijuoti ant plokščių butelių ir korpusų, apvynioti apvalias etiketes ant apvalių formų butelių. Be to, ji taip pat turi visas pagrindines standartinio modelio savybes, atitinkančias dabartinę rinką.