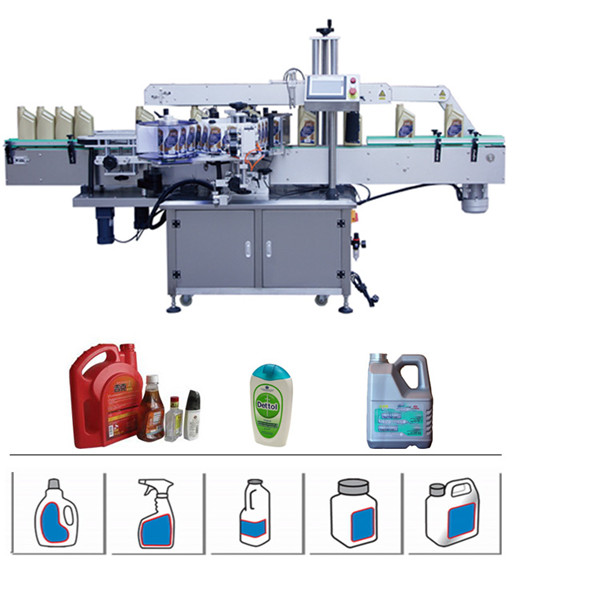

Automātiska pašlīmējoša pudeļu marķēšanas mašīna

Automātiska pašlīmējošā pudeļu marķēšanas iekārta ir piemērota daudzu veidu pudeļu marķēšanai. Marķēšanas laikā pudele automātiski griežas, lai marķēšanas ierīce varētu pielikt spiedienu marķēšanai.

Automātiska pašlīmējošā pudeļu marķēšanas iekārta ir piemērota daudzu veidu pudeļu marķēšanai. Marķēšanas laikā pudele automātiski griežas, lai marķēšanas ierīce varētu pielikt spiedienu marķēšanai.

Piemērots medicīnas, pārtikas, dzērienu un ķīmiskajai rūpniecībai. Var izmantot plastmasas, stikla, metāla un citiem apaļiem traukiem/pudelēm. Pateicoties inovatīvajam dizainam, tā darbība ir tik vienkārša, ka to var izmantot pat primitīvs cilvēks.

Apraksts

Būtībā etiķešu līmēšanas iekārta tiek izmantota, lai automātiski uzlīmētu etiķetes uz produktiem, traukiem, pudelēm utt. Manuāla marķēšana var būt laikietilpīgs un neprofesionāls produkta iepakošanas veids. Sen atpakaļ, kad etiķešu līmēšanas iekārtas vēl nebija izgudrotas, pudeles, burkas, trauki utt. tika marķēti manuāli, kas bija ilgs un laikietilpīgs process. Taču tagad etiķešu līmēšanas iekārtas ir kļuvušas par svētību nozarēm. Runājot par produktu vairumtirdzniecību, nav cita veida, kā marķēt produktus, kā vien izmantot etiķešu līmēšanas iekārtu. Tāpēc etiķešu līmēšanas iekārta tiek izmantota daudzu nozaru, piemēram, farmācijas, kosmētikas, ātrās aprites patēriņa preču, pārtikas un dzērienu utt., iepakošanas procesā.

Iepakojuma veids: Pudeles

Iepakojuma materiāls: papīrs

Tips: Marķēšanas mašīna, Marķēšanas mašīna

Stāvoklis: Jauns

Pēcpārdošanas serviss: tiešsaistes atbalsts, video tehniskais atbalsts, bezmaksas rezerves daļas, uzstādīšana uz vietas, nodošana ekspluatācijā un apmācība, inženieri, kas pieejami tehnikas apkalpošanai ārzemēs

Izcelsmes vieta: Šanhaja, Ķīna

Zīmola nosaukums: VKPAK

Spriegums: 220 V 50/60 Hz

Pielietojums: dzērieni, ķīmiskā viela, pārtika, medicīna

Automātiska pakāpe: Automātiska

Sertifikācija: ISO9001

Piedziņas tips: mehānisks

Izmēri (G*P*A): 1800mm*1000mm*1300mm

Funkcija: uzlīmes etiķete uz pudeles

Marķēšanas ātrums: 20–100 pudeles/min

Motors: servomotors

Materiāls: Nerūsējošais tērauds

garantija: 1 gads

Marķēšanas precizitāte: 1 mm

Pakalpojums: Tehniskais atbalsts visu diennakti

Iepakojums: Koka kaste tālsatiksmē

Tehniskais parametrs

| Modelis/tehniskie parametri | VK-DSL |

| Marķēšanas ātrums (gab./min) | 40–100 (atkarībā no materiāla un etiķetes izmēra) |

| Marķēšanas precizitāte (mm) | ±1,0 mm (materiāla un etiķešu izmēri netiek ieskaitīti) |

| Etiķetes izmērs (mm) | (G) 20–280 mm (A) 30–144 mm |

| Materiāla izmērs (mm) | Φ20–φ100 mm (augstums) 40–200 mm |

| Ruļļa iekšpuse (mm) | φ76 mm |

| Ruļļa ārējais diametrs (mm) | Maks.: Φ350 mm |

| Mašīnas izmērs (mm) | (G) 2000 * (P) 850 * (A) 1450 (mm) |

| Barošanas avots | Maiņstrāva 220 V 50 Hz/60 Hz 1500 W |

- Stabila adaptācijas Siemens PLC vadība un Panasonic servomotora vadīta etiķete nodrošina mašīnas stabilu darbību un etiķešu precizitāti. Tā ir augsta veiktspēja un augsta efektivitāte.

- Vienkārša lietošana — skārienekrāns var būt angļu, spāņu, franču, krievu un jebkurā citā valodā. To ir viegli lietot, un to var savienot ar citām ražošanas iepakošanas līnijas iekārtām.

- Augsta precizitāte — precizitāte no +/- 0,5–1 mm. Plašs pielietojuma diapazons — plaši izmanto pudeles diametru no 25 mm līdz 120 mm, pudeles augstumu no 25 mm līdz 300 mm. Ja pielāgots augstums no 10 mm līdz 150 mm, garums no 15 mm līdz 300 mm, lūdzu, jautājiet mums.

- Liels ātrums — maksimālais ātrums var sasniegt 150 pudeles minūtē atkarībā no etiķetes un pudeles izmēra.

- Eiropas standarts — marķēšanas mašīna ir izgatavota saskaņā ar CE standartu, Taivānas tehnoloģiju.

Detalizēti attēli

Pudeļu marķēšanas mašīnas darba process

- Manuāli novietojiet pudeles uz konveijera vai izmantojot automātisko pudeļu grozāmo galdu

Un pudeles tiks atdalītas ar pudeļu atdalītāju, lai saglabātu katras pudeles attālumu, lai garantētu darba stabilitāti. - Visas darbības kontrolē PLC, automātiski uztver pudeli un etiķetes, automātiski uzliek etiķetes uz abām pudeļu pusēm. Un mašīna ar funkciju, ja nav pudeles, nav etiķetes, automātisks brīdinājums, ja nav etiķetes vai tās trūkst.

- Pēc etiķešu uzlikšanas uz pudelēm etiķešu ielīmēšanas ierīce ielīmēs etiķetes, lai piestiprinātu etiķeti pie pudelēm.

- Tad pudele dodas uz nākamo apstrādes posmu

Galvenās iezīmes:

- Pieņem pakāpju servodzinēju, PLC vadības sistēmu, krāsu skārienekrānu.

- Izmantojiet Japānas fotosensoru, lai automātiski noteiktu un pārbaudītu etiķešu garumu

- Aprīkots ar brīdinājuma ierīci par nepietiekamu etiķešu skaitu, bojātām etiķetēm un hroma lentu trūkumu.

- Precīza etiķetes pozīcija, liels ātrums un augsta marķēšanas precizitāte.

- Automātiska noteikšana, nav konteinera, nav marķējuma.

- Mašīnas korpuss ir izgatavots no nerūsējošā tērauda, pilnībā atbilst GMP prasībām

- To var instalēt ar kodēšanas/tintes printeri (pēc izvēles).

Pašlīmējošās uzlīmju marķēšanas iekārta ir pilnībā automatizēta, vertikāla un lineāra. Šim vairāku iepakojumu modelim ir vairākas lietotājam draudzīgas funkcijas. Tā ir vispiemērotākā iekārta priekšējo, aizmugurējo vai sānu etiķešu uzlikšanai uz plakaniem, ovāliem, kvadrātveida un apaļiem traukiem. Šī izturīgā iekārta var nodrošināt maksimālo jaudu 100 etiķetes vienā minūtē atkarībā no produktu formas un izmēra, kā arī etiķetes izmēra. Tajā ir iekļauta arī automātiska un sinhronizēta sistēma produkta izlīdzināšanai ar augšējo turēšanas lentes sistēmu. Vēl viens lielisks šīs iekārtas elements ir uzlabota mikroprocesora vadīta etiķešu padeves sistēma ar jaunāko etiķešu un produktu uztveršanas sistēmu. Šī daudzfunkcionālā, ātrdarbīgā marķēšanas iekārta ir efektīva, precīza un izturīga. Tā ir izstrādāta, lai apmierinātu lietotāju dažādās prasības mūsdienu iepakošanas līnijās. Šai vienkārši lietojamai un viegli regulējamai iekārtai ir nepieciešams minimāls instrumentu un detaļu maiņas apjoms. To var speciāli konstruēt ar padeves tārpu un kabatu sistēmu, lai nodrošinātu pareizu pudeļu izlīdzināšanu uz konveijera precīzai marķēšanai. Šajā modelī ir iekļauta pat ekskluzīva viena punkta sinhronizēta ātruma kontroles sistēma. Turklāt iebūvētā un iepriekš iestatītā etiķetes garuma noteikšanas sistēma ļauj izvairīties no manuālas etiķetes garuma datu padeves un saglabāšanas atmiņā un tos izgūt katru reizi, kad vēlaties mainīt etiķetes izmēru un restartēt iekārtu. Tādējādi tas ietaupa jūsu laiku, novērš iekārtas dīkstāvi un uzlabo produktivitāti. Tā ir pieejama arī ar papildu drošības skapi, kas izgatavots no izturīga stikla vai akrila. Šo iekārtu var īpaši izstrādāt, lai uzlīmētu vienpusējas etiķetes uz plakanām pudelēm un korpusa, kā arī lai aptītu apaļas etiķetes uz apaļas formas pudelēm. Turklāt tai ir arī visas standarta modeļa būtiskās īpašības atbilstoši pašreizējam tirgum.