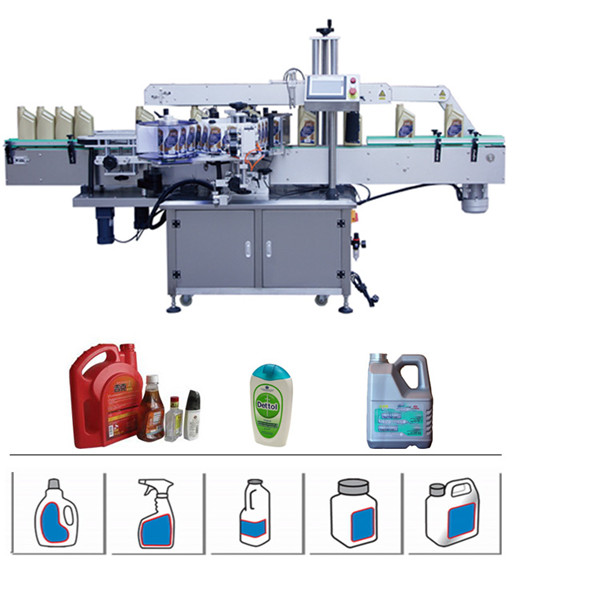

Automatische zelfklevende flesetiketteermachine

De automatische zelfklevende flessenetiketteermachine is geschikt voor vele soorten etikettering. Tijdens het etiketteren draait de fles automatisch, zodat het etiketteerapparaat druk kan uitoefenen om te etiketteren.

De automatische zelfklevende flessenetiketteermachine is geschikt voor vele soorten etikettering. Tijdens het etiketteren draait de fles automatisch, zodat het etiketteerapparaat druk kan uitoefenen om te etiketteren.

Geschikt voor de farmaceutische, voedingsmiddelen-, dranken- en chemische industrie. Kan gebruikt worden voor plastic, glas, metaal en andere ronde containers/flessen. Dankzij het innovatieve ontwerp is de bediening zo eenvoudig dat zelfs een primitieve mens ermee overweg kan.

Beschrijving

In principe wordt een etiketteermachine gebruikt om automatisch etiketten op producten, verpakkingen, flessen, enz. te plakken. Handmatig etiketteren kan een tijdrovende en onprofessionele manier zijn om een product te verpakken. Lang geleden, toen de etiketteermachines nog niet waren uitgevonden, werd het etiketteren handmatig gedaan op flessen, potten, containers, enz., wat een langdurig en tijdrovend proces was. Maar nu zijn etiketteermachines een zegen voor de industrie geworden. Als het gaat om het verpakken van bulkproducten, is er geen andere manier om de producten te etiketteren dan met een etiketteermachine. Daarom worden etiketteermachines gebruikt in de verpakkingsprocessen van vele industrieën, zoals de farmaceutische, cosmetische, FMCG-, voedingsmiddelen- en drankenindustrie.

Verpakkingstype: Flessen

Verpakkingsmateriaal: papier

Type: Etiketteermachine, Etiketteermachine

Staat: Nieuw

Aftersales-service: online ondersteuning, videotechnische ondersteuning, gratis reserveonderdelen, installatie ter plaatse, inbedrijfstelling en training, technici beschikbaar om machines in het buitenland te onderhouden

Plaats van herkomst: Shanghai, China

Merknaam: VKPAK

Spanning: 220V 50/60HZ

Toepassing: Dranken, Chemie, Voedsel, Medisch

Automatische beoordeling: Automatisch

Certificering: ISO9001

Aangedreven type: Mechanisch

Afmetingen (L*B*H): 1800mm*1000mm*1300mm

Functie: stickeretiket op de fles

Etiketteringssnelheid: 20-100 flessen / min

Motor: servomotor

Materiaal: roestvrij staal

garantie: 1 jaar

etiketteringsnauwkeurigheid: 1 mm

Service: 24/7 technische ondersteuning

verpakking: Houten kist voor lange afstanden

Technische parameter

| Model / technische parameters | VK-DSL |

| Etiketteringssnelheid (stuks/min) | 40-100 (afhankelijk van materiaal en etiketformaat) |

| Etiketteringsnauwkeurigheid (mm) | ±1,0 mm (materiaal- en etiketafmetingen worden niet meegerekend) |

| Etiketgrootte (mm) | (L)20-280mm (H)30-144mm |

| Materiaalgrootte (mm) | Φ20-φ100mm (H)40-200mm |

| Rol binnen (mm) | φ76mm |

| Buitendiameter rol (mm) | Max:Φ350mm |

| Machinegrootte (mm) | (L)2000*(B)850*(H)1450(mm) |

| Stroomvoorziening | AC220V 50Hz/60Hz 1500W |

- Stabiele, aanpasbare Siemens PLC-besturing en Panasonic servomotor zorgen voor een stabiele werking en nauwkeurige etikettering. Hoge prestaties en hoge efficiëntie.

- Eenvoudige bediening - Het touchscreen is beschikbaar in het Engels, Spaans, Frans, Russisch en elke andere taal. Het is eenvoudig te bedienen en kan worden aangesloten op andere machines voor de productie- en verpakkingslijn.

- Hoge precisie - Nauwkeurigheid van +-0,5-1 mm. Breed toepassingsbereik - Breed gebruik van flesdiameters van 25 mm tot 120 mm, fleshoogtes van 25 mm tot 300 mm. Als u een aangepaste hoogte van 10 mm tot 150 mm of lengte van 15 mm tot 300 mm wenst, neem dan contact met ons op.

- Hoge snelheid: de maximale snelheid kan 150 flessen per minuut bereiken, afhankelijk van de grootte van het etiket en de fles.

- Europese norm: de etiketteermachine is vervaardigd volgens de CE-norm en met Taiwanese technologie.

Gedetailleerde afbeeldingen

Werkproces van de flessenetiketteermachine

- Flessen handmatig op de transportband plaatsen of een automatische flessendraaitafel gebruiken

En de flessen worden gescheiden door een flessenscheider om de afstand tussen de flessen te behouden en zo een stabiele werking te garanderen - Alle handelingen worden aangestuurd door PLC. De fles en de etiketten worden automatisch gedetecteerd en de etiketten worden automatisch aan beide zijden van de fles aangebracht. De machine heeft een functie: geen fles, geen etiket, automatische waarschuwing bij ontbreken of ontbreken van etiketten.

- Nadat de etiketten op de flessen zijn geplakt, plakt het etikettenplakapparaat de etiketten op de flessen.

- Ga dan met de fles naar de volgende verwerking

Belangrijkste kenmerken:

- Maakt gebruik van een stappenmotor, PLC-besturingssysteem en een kleurentouchscreen.

- Gebruik een Japanse fotosensor om de lengte van etiketten automatisch te detecteren en te controleren

- Uitgerust met een waarschuwingsapparaat bij onvoldoende labels, gebroken labels en ontbrekende chroma-tapes.

- Nauwkeurige etiketpositie, hoge snelheid en hoge etiketteringsprecisie.

- Automatische detectie, geen container, geen etikettering.

- De machinebehuizing is gemaakt van roestvrij staal en voldoet volledig aan de GMP-vereisten.

- Kan worden geïnstalleerd met een codeer-/inkjetprinter (optioneel).

De zelfklevende etiketteermachine is volledig geautomatiseerd, verticaal en lineair. Dit multipackmodel beschikt over een aantal gebruiksvriendelijke functies. Het is de meest geschikte machine voor het aanbrengen van etiketten op de voor-, achter- of zijkant op vlakke, ovale, vierkante en ronde verpakkingen. Deze robuuste machine kan een maximale output van 100 etiketten per minuut leveren, afhankelijk van de vorm en grootte van de producten en de etiketgrootte. De machine is tevens voorzien van een automatisch en gesynchroniseerd systeem voor het uitlijnen van het product met de bovenste transportband. Een ander uitstekend element van deze machine is het geavanceerde microprocessorgestuurde etikettendoseersysteem, met de nieuwste sensoren voor etiketten en producten. Deze multifunctionele, snelle etiketteermachine is efficiënt, nauwkeurig en duurzaam. De machine is gebouwd om te voldoen aan de uiteenlopende eisen van gebruikers in moderne verpakkingslijnen. Deze eenvoudig te bedienen en eenvoudig af te stellen machine vereist minimale gereedschaps- en onderdeelwissels. De machine kan speciaal worden ontworpen met een transportworm en een zakkensysteem om een correcte uitlijning van de flessen op de transportband te garanderen voor nauwkeurige etikettering. Dit model is zelfs voorzien van een exclusief gesynchroniseerd snelheidsregelsysteem met één punt. Bovendien voorkomt het ingebouwde en vooraf ingestelde detectiesysteem voor de etiketlengte handmatige invoer en opslag van de etiketlengtegegevens in het geheugen, zodat deze telkens opnieuw kunnen worden opgeroepen om de etiketgrootte te wijzigen en de machine opnieuw te starten. Dit bespaart u tijd, voorkomt machine-uitval en verhoogt de productiviteit. Het systeem is ook verkrijgbaar met een optionele veiligheidskast van gehard glas of acryl. Deze machine kan speciaal worden ontworpen voor het aanbrengen van enkelzijdige etiketten op vlakke flessen en body's, en voor het aanbrengen van ronde etiketten op ronde flessen. Bovendien beschikt het over alle essentiële kenmerken van een standaardmodel dat momenteel op de markt is.