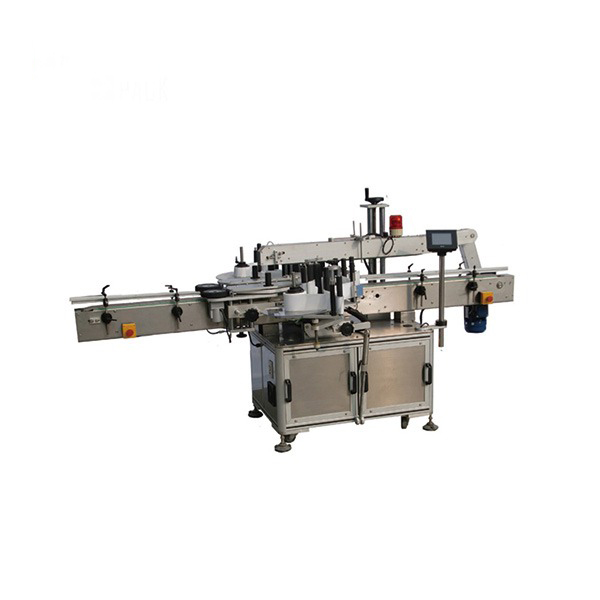

Mașină automată de etichetare a sticlelor plate

Această mașină automată de etichetare a sticlelor plate poate separa sticla, un motor acționează controlul dispozitivului de presare a sticlei și al transportorului, sticla se va mișca liniar pe transportor. Servomotorul, PLC-ul și ecranul tactil vor eticheta de înaltă calitate.

Această mașină automată de etichetare a sticlelor plate poate separa sticla, un motor acționează controlul dispozitivului de presare a sticlei și al transportorului, sticla se va mișca liniar pe transportor. Servomotorul, PLC-ul și ecranul tactil vor eticheta de înaltă calitate.

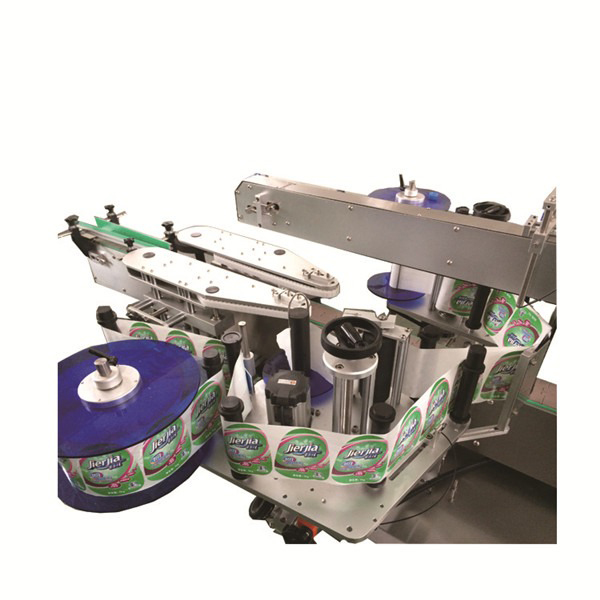

Mașina automată de etichetat sticle plate este proiectată pe o bază cu două fețe pentru sticle plate, sticle pătrate. Pentru a satisface cerințele clienților privind etichetarea pe două fețe și a sticlelor rotunde. Este vorba de medicamente, substanțe chimice de zi cu zi, consumabile alimentare, electronice etc. Această mașină controlează servomotorul, PLC-ul și ecranul tactil, fiind o mașină de etichetat multi-sticker/adeziv.

Descriere

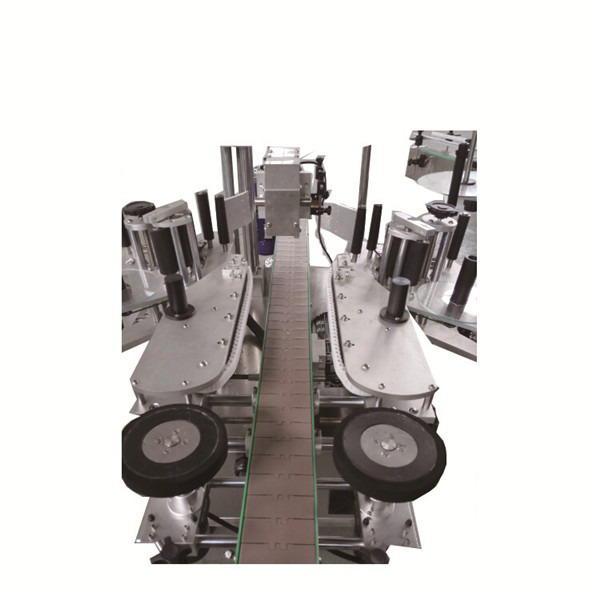

Mașina de etichetat cu autocolante plate este utilizată pentru a eticheta o parte a recipientelor plate; sau etichete complete și parțiale înfășurate pe diferite dimensiuni ale altor recipiente. Această mașină robustă are un finisaj neted din oțel inoxidabil, care include și cadrul principal. Este cel mai ușor de utilizat echipament, cu o capacitate de etichetare de la 30 la 350 de unități pe minut, în funcție de dimensiunea produsului și a etichetei. Viteza depinde, de asemenea, de mișcarea stabilă a recipientului pe transportorul mașinii la o viteză mai mare. Acest model sofisticat și simplu are cel mai recent dispozitiv de distanțare a benzii, care are ca rezultat un sistem fără schimbarea pieselor, chiar dacă dimensiunea recipientelor și a etichetelor este modificată. Mai mult, mașina include un sistem avansat și distinct de control într-un singur punct pentru variația online a vitezei. În plus, acest echipament versatil și precis este renumit pentru precizia ridicată de plasare a etichetelor. De asemenea, încorporează un sistem integrat de acționare a frecvenței AC.

Tip ambalaj: Sticle

Material de ambalare: Metal

Tip: Mașină de etichetat, Mașină de etichetat

Stare: Nou

Servicii post-vânzare oferite: asistență online, asistență tehnică video, piese de schimb gratuite, instalare pe teren, punere în funcțiune și instruire

Locul de origine: Shanghai, China

Numele mărcii: VKPAK

Tensiune: 220V 50/60HZ

Aplicație: Îmbrăcăminte, Băuturi, Chimice, Alimente, Medicale

Greutate: 200 kg

Grad automat: Automat

Tip acționat: Mecanic

Dimensiuni (L*l*Î): 1800mm*1000mm*1300mm

Funcție: etichetă autocolantă pe sticlă

Viteză de etichetare: 20-100 sticle/min

Motor: servomotor

Numele mașinii: mașină de aplicare a etichetelor

Material: Oțel inoxidabil

garanție: 1 an

precizie de etichetare: 1 mm

Serviciu: Asistență tehnică 24/7

ambalare: Cutie din lemn pentru distanțe lungi

Parametru tehnic

| Nume | Mașină automată de etichetare a sticlelor plate |

| Viteză de etichetare | 60-350 buc/min (În funcție de lungimea etichetei și grosimea sticlei) |

| Înălțimea obiectului | 30-350 mm |

| Grosimea obiectului | 20-120 mm |

| Înălțimea etichetei | 15-140 mm |

| Lungimea etichetei | 25-300 mm |

| Diametrul interior al rolei de etichetare | 76 mm |

| Diametrul exterior al rolei de etichetare | 420 mm |

| Acuratețea etichetării | ±1mm |

| Alimentare electrică | 220V 50/60HZ 3.5KW Monofazat |

| Consumul de combustibil al imprimantei | 5 kg/cm² |

| Dimensiunea mașinii de etichetat | 2800 (L) × 1650 (l) × 1500 (Î) mm |

| Greutatea mașinii de etichetat | 450 kg |

Caracteristici principale:

- PLC și ecran tactil, servomotor

- Echipat cu dispozitiv de avertizare pentru etichete insuficiente sau etichete rupte

- Fără sticlă, fără etichetă

- Fără etichete, fără etichetare și avertizare automată

- Fără panglică, avertizare automată

- Controlul servomotorului, etichetare stabilă.

- Senzorul de etichetă și componentele electrice sunt fabricate în Japonia

- Potrivit pentru sticla rotundă/plată/pătrată

Mașina poate utiliza etichete cu o lungime minimă de 12 mm și o înălțime cuprinsă între 8 mm și 70/90/120/150 mm. De obicei, diametrul rolei este de 300 mm, iar diametrul miezului este de 75 mm. Distanța dintre cele două etichete este de aproximativ 3 mm. În plus, are un sistem încorporat de detectare automată a lungimii etichetei, care elimină sistemul de alimentare manuală și stocare a detaliilor lungimii etichetei în memorie și recuperarea acelorași date atunci când dimensiunea etichetei este modificată și mașina este repornită. Acest sistem modern economisește costuri generale, timp prețios, evită timpul de nefuncționare a mașinii și permite obținerea unei productivități mai mari. Acest model este disponibil opțional cu o carcasă de siguranță robustă din sticlă sau acril. De fapt, îndeplinește toate nevoile de bază ale unei mașini tipice cerute pe piața actuală.