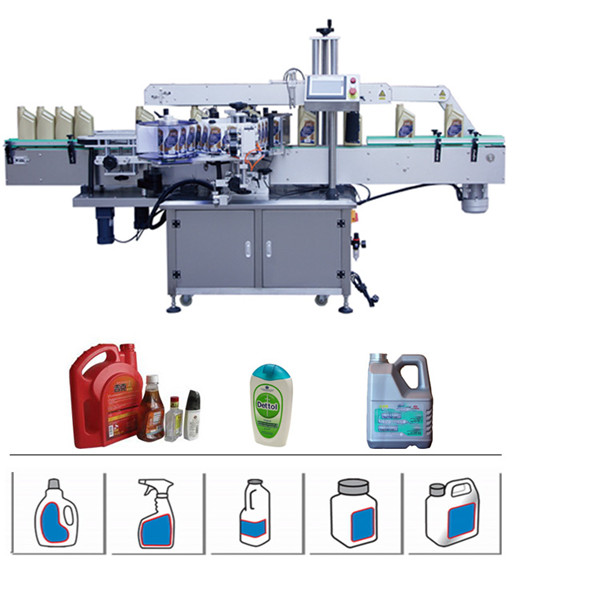

Automatisk självhäftande flaskmärkningsmaskin

Automatisk självhäftande flaskmärkningsmaskin är lämplig för många olika typer av flaskmärkning. Vid märkning roterar flaskan automatiskt för att låta märkningsenheten applicera tryck för märkning.

Automatisk självhäftande flaskmärkningsmaskin är lämplig för många olika typer av flaskmärkning. Vid märkning roterar flaskan automatiskt för att låta märkningsenheten applicera tryck för märkning.

Lämplig för medicin-, livsmedels-, dryckes- och kemisk industri. Kan användas för plast-, glas-, metall- och andra runda behållare/flaskor. Med sin innovativa design är dess användning så enkel att även en primitiv människa kan använda den.

Beskrivning

I grund och botten används en etiketteringsmaskin för att automatiskt klistra etiketter på produkter, behållare, flaskor etc. Manuell etikettering kan vara ett tidskrävande och oprofessionellt sätt att förpacka en produkt. För länge sedan, när etiketteringsmaskiner inte uppfanns, gjordes etikettering manuellt på flaskor, burkar, behållare etc., vilket var en långdragen och tidskrävande process. Men nu har etiketteringsmaskiner blivit en välsignelse för industrier. När det gäller bulkförpackning av produkter finns det inget annat sätt att märka produkterna än att använda en etiketteringsmaskin. Så etiketteringsmaskiner används i förpackningsprocesser inom många industrier som läkemedel, kosmetika, dagligvaror, livsmedel och drycker etc.

Förpackningstyp: Flaskor

Förpackningsmaterial: Papper

Typ: Märkningsmaskin, Märkningsmaskin

Skick: Nytt

Eftermarknadsservice: Onlinesupport, teknisk videosupport, kostnadsfria reservdelar, installation, driftsättning och utbildning på fältet, ingenjörer tillgängliga för att serva maskiner utomlands

Ursprungsort: Shanghai, Kina

Varumärke: VKPAK

Spänning: 220V 50/60HZ

Användningsområden: Dryck, Kemikalier, Livsmedel, Medicin

Automatisk betyg: Automatisk

Certifiering: ISO9001

Drivtyp: Mekanisk

Mått (L*B*H): 1800 mm * 1000 mm * 1300 mm

Funktion: klistermärke på flaskan

Märkningshastighet: 20-100 flaskor/min

Motor: servomotor

Material: Rostfritt stål

garanti: 1 år

märkningsnoggrannhet: 1 mm

Service: Teknisk support dygnet runt

förpackning: Trälåda för långdistans

Teknisk parameter

| Modell / tekniska parametrar | VK-DSL |

| Märkningshastighet (st/min) | 40-100 (beroende på material och etikettstorlek) |

| Märkningsnoggrannhet (mm) | ±1,0 mm (material- och etikettstorlekar räknas inte med) |

| Etikettstorlek (mm) | (L) 20–280 mm (H) 30–144 mm |

| Materialstorlek (mm) | Φ20-φ100mm (H)40-200mm |

| Rulla inuti (mm) | φ76 mm |

| Rullens ytterdiameter (mm) | Max: Φ350mm |

| Maskinstorlek (mm) | (L)2000*(B)850*(H)1450(mm) |

| Strömförsörjning | AC220V 50Hz/60Hz 1500W |

- Stabil - Anpassad Siemens PLC-styrning och Panasonic servomotordriven etikett för stabil maskindrift och etikettnoggrannhet. Den är högpresterande och hög effektivitet.

- Enkel användning - Pekskärmen kan vara på engelska, spanska, franska, ryska och vilket annat språk som helst. Den är enkel att använda och kan anslutas till andra maskiner för produktionsförpackningslinjen.

- Hög precision - Noggrannhet från +-0,5-1 mm. Brett användningsområde - Brett användningsområde för flaskdiameter från 25 mm till 120 mm, flaskhöjd 25 mm till 300 mm. Om anpassad höjd på 10 mm-150 mm, längd på 15 mm-300 mm, vänligen fråga oss.

- Hög hastighet - Maxhastigheten kan nå 150 flaskor per minut beroende på etikettstorlek och flaskstorlek.

- Europeisk standard - Märkningsmaskinen är tillverkad enligt CE-standard, Taiwan-teknik.

Detaljbilder

Arbetsprocess för flaskmärkningsmaskin

- Placera flaskor manuellt på transportband eller använd en automatisk flaskvändare

Och flaskorna kommer att separeras med flaskseparator för att hålla avståndet mellan flaskorna och garantera att de fungerar stabilt. - Alla åtgärder styrs av PLC, automatisk avkänning av flaskan och etiketterna, automatisk applicering av etiketter på flaskornas båda sidor. Och maskin med funktion, ingen flaska, ingen märkning, automatisk varning om ingen etikett eller avsaknad av etiketter.

- Efter att etiketterna har applicerats på flaskorna, klistrar etikettklistraren etiketterna för att fästa etiketten på flaskorna.

- Sedan går flaskan till nästa bearbetning

Huvudfunktioner:

- Använder stegmotor, PLC-styrsystem och pekskärm i färg.

- Använd en japansk fotosensor för att automatiskt upptäcka och kontrollera etiketternas längd

- Utrustad med varningsanordning för otillräckliga etiketter, trasiga etiketter och inga kromatejper.

- Noggrann etikettpositionering, snabb hastighet och hög märkningsprecision.

- Automatisk detektering, ingen behållare ingen märkning.

- Maskinhuset är tillverkat av rostfritt stål och uppfyller helt GMP-kraven

- Den kan installeras med kodnings-/bläckstråleskrivare (valfritt).

Den självhäftande etiketteringsmaskinen är helautomatiserad, vertikal och linjär. Denna multipackmodell har ett antal användarvänliga funktioner. Det är den mest lämpliga utrustningen för att applicera etiketter på fram-, bak- eller sidosidan av platta, ovala, fyrkantiga och runda behållare. Denna robusta maskin kan ge en maximal produktion på 100 etiketter på en minut, beroende på produkternas form och storlek samt etikettstorleken. Den har också ett automatiskt och synkroniserat system för att justera produkten mot det övre bandsystemet. En annan utmärkt del av denna utrustning är det avancerade mikroprocessorstyrda etikettdispenseringssystemet, med det senaste sensorsystemet för etiketter och produkter. Denna mångsidiga, höghastighetsetiketteringsmaskin är effektiv, exakt och hållbar. Den är byggd för att uppfylla de olika kraven från användarna i moderna förpackningslinjer. Denna enkla att använda och justera maskin kräver minimala verktyg och byte av delar. Den kan specialdesignas med en matarmask och ett ficksystem för att säkerställa korrekt inriktning av flaskorna på transportbandet för korrekt märkning. Denna modell har till och med ett exklusivt synkroniserat hastighetskontrollsystem med en punkt. Dessutom möjliggör det inbyggda och förinställda systemet för detektering av etikettlängd att undvika manuell matning och lagring av etikettlängdsdata i minnet och hämta den varje gång man ändrar etikettstorleken och startar om utrustningen. Därmed sparar det tid, förhindrar maskinstopp och ökar produktiviteten. Den finns också tillgänglig med ett valfritt säkerhetsskåp tillverkat av hårt glas eller akryl. Denna utrustning kan specialdesignas för att applicera enkelsidiga etiketter på platta flaskor och flaskor, och linda runda etiketter på runda flaskor. Dessutom har den alla väsentliga egenskaper hos en standardmodell enligt den nuvarande marknaden.