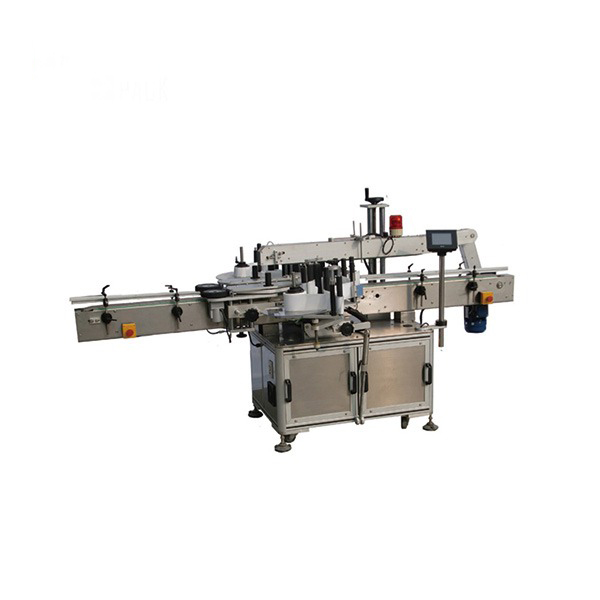

Otomatik Düz Şişe Etiketleme Makinesi

Bu Otomatik Düz Şişe Etiketleme Makinesi şişeyi ayırabilir, bir motor sürücüsü pres şişe cihazını ve konveyörü kontrol eder, şişe konveyör üzerinde doğrusal olarak hareket edecektir. Servo motor, PLC ve Dokunmatik ekran yüksek etiketli olacaktır.

Bu Otomatik Düz Şişe Etiketleme Makinesi şişeyi ayırabilir, bir motor sürücüsü pres şişe cihazını ve konveyörü kontrol eder, şişe konveyör üzerinde doğrusal olarak hareket edecektir. Servo motor, PLC ve Dokunmatik ekran yüksek etiketli olacaktır.

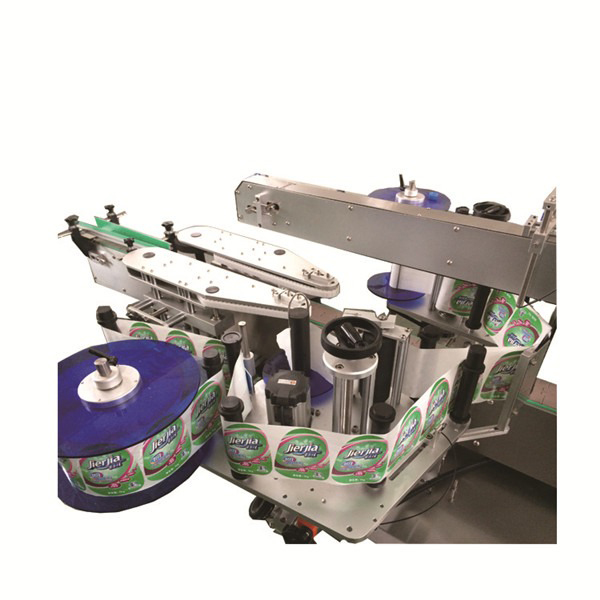

Otomatik Düz Şişe Etiketleme Makinesi, düz ve kare şişeler için iki taraflı etiketleme esasına göre tasarlanmıştır. Müşterilerin iki taraflı etiketleme ve yuvarlak şişeler gibi ilaç, günlük kimyasal, gıda, kültürel malzeme, elektronik vb. şişeleri etiketleme gereksinimlerini karşılamak için tasarlanmıştır. Bu makine, servo motor, PLC ve dokunmatik ekran ile kontrol edilir ve çoklu etiket/yapışkanlı etiketleme makinesidir.

Tanım

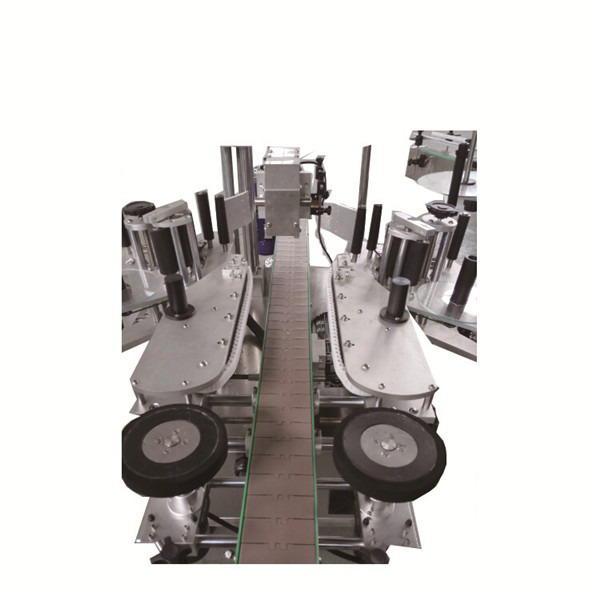

Düz etiket etiketleme makinesi, düz kapların bir tarafını etiketlemek veya diğer kapların çeşitli boyutlarına tam ve kısmi sarma etiketleri yapıştırmak için kullanılır. Bu sağlam makine, ana gövdeyi de içeren pürüzsüz paslanmaz çelik kaplamaya sahiptir. Ürün ve etiket boyutuna göre dakikada 30 ila 350 adet etiketleme kapasitesiyle en kullanıcı dostu ekipmandır. Hız ayrıca, kabın makine konveyöründe daha yüksek bir hızda istikrarlı hareketine de bağlıdır. Bu sofistike ve basit model, kapların ve etiketlerin boyutu değişse bile parça değişimi gerektirmeyen en yeni bant aralıklandırma cihazına sahiptir. Ayrıca, makine çevrimiçi hız değişimi için gelişmiş ve belirgin bir tek nokta kontrol sistemine sahiptir. Ayrıca, bu çok yönlü ve hassas ekipman yüksek etiket yerleştirme doğruluğu ile ünlüdür. Ayrıca entegre bir AC frekans sürücü sistemine sahiptir.

Ambalaj Türü: Şişeler

Ambalaj Malzemesi: Metal

Tür: Etiketleme Makinesi, Etiketleme Makinesi

Durum: Yeni

Satış Sonrası Hizmet Sağlanır: Çevrimiçi destek, Video teknik desteği, Ücretsiz yedek parça, Saha kurulumu, devreye alma ve eğitim

Menşei: Şanghay, Çin

Marka Adı: VKPAK

Voltaj: 220V 50/60HZ

Uygulama: Giyim, İçecek, Kimyasal, Gıda, Tıbbi

Ağırlık: 200kg

Otomatik Sınıf: Otomatik

Tahrik Tipi: Mekanik

Boyutlar (U*G*Y): 1800mm*1000mm*1300mm

İşlev: Şişe üzerindeki çıkartma etiketi

Etiketleme hızı: 20-100 şişe / dk

Motor: servo motor

Makine adı: etiket uygulama makinesi

Malzeme: Paslanmaz Çelik

garanti: 1 yıl

etiketleme doğruluğu: 1 mm

Hizmet: 7/24 Teknik Destek

ambalaj: Uzun Mesafe Ahşap Kasa

Teknik Parametre

| İsim | Otomatik Düz Şişe Etiketleme Makinesi |

| Etiketleme Hızı | 60-350 adet/dak (Etiket uzunluğuna ve şişe kalınlığına bağlı olarak) |

| Nesnenin Yüksekliği | 30-350 mm |

| Nesnenin Kalınlığı | 20-120 mm |

| Etiket Yüksekliği | 15-140 mm |

| Etiket Uzunluğu | 25-300 mm |

| Etiket Rulosu İç Çapı | 76 mm |

| Etiket Rulosu Dış Çapı | 420 mm |

| Etiketlemenin Doğruluğu | ±1mm |

| Güç Kaynağı | 220V 50/60HZ 3,5KW Tek fazlı |

| Yazıcının Gaz Tüketimi | 5Kg/cm^2 |

| Etiketleme Makinesinin Boyutu | 2800(U)×1650(G)×1500(Y)mm |

| Etiketleme Makinesinin Ağırlığı | 450 kg |

Başlıca Özellikler:

- PLC ve dokunmatik ekran, servo motor

- Yetersiz etiket, kırık etiket uyarı cihazı ile donatılmıştır

- Şişe yok, etiketleme yok

- Etiket yok, etiketleme yok ve otomatik uyarı

- Şerit Yok, otomatik uyarı

- Servo motor kontrolü, stabil etiketleme.

- Etiket sensörü ve elektrik parçaları Japonya'da üretilmiştir

- Yuvarlak / düz / kare şişeler için uygundur

Makine, minimum 12 mm uzunluğunda ve 8 mm ile 70/90/120/150 mm arasında değişen yükseklikteki etiketleri kullanabilir. Genellikle rulo çapı 300 mm ve çekirdek çapı 75 mm'dir. İki etiket arasındaki boşluk ise yaklaşık 3 mm'dir. Ayrıca, etiket uzunluğu bilgilerini manuel olarak belleğe kaydetme ve etiket boyutu değiştirildiğinde ve makine yeniden başlatıldığında aynı verileri alma sistemini ortadan kaldıran dahili bir otomatik etiket uzunluğu algılama sistemine sahiptir. Bu modern sistem genel maliyetten ve değerli zamandan tasarruf sağlar, makinenin çalışmama süresini önler ve daha yüksek üretkenliğe ulaşmayı sağlar. Bu model, isteğe bağlı olarak sağlam cam veya akrilik güvenlik kabiniyle mevcuttur. Aslında, mevcut pazardaki tipik bir makinenin ihtiyaç duyduğu tüm temel ihtiyaçları karşılar.