自動活塞式黏稠液體填充機

應用:

這款活塞式灌裝機最適合灌裝膏狀、半膏狀或含有大顆粒的黏稠產品。這些活塞式填充機符合食品級標準,也可用於各種化學應用。.

例如:

濃稠的醬汁、莎莎醬、沙拉醬、化妝霜、濃稠的洗髮精、啫咖哩和護髮素、膏狀清潔劑和蠟、黏合劑、濃稠的油和潤滑劑。.

優勢:

這種成本較低的傳統填充技術易於大多數用戶理解。即使是較濃稠的產品,也能實現快速填充。警告:隨著伺服容積式填充機的出現,這項技術已基本過時。.

描述

這款灌裝機為活塞式填充機,適用於灌裝各種黏度的流體。該機採用直列式結構,灌裝頭數量可根據不同的生產能力定制,例如6/8/10/12/16/20個填充頭。.

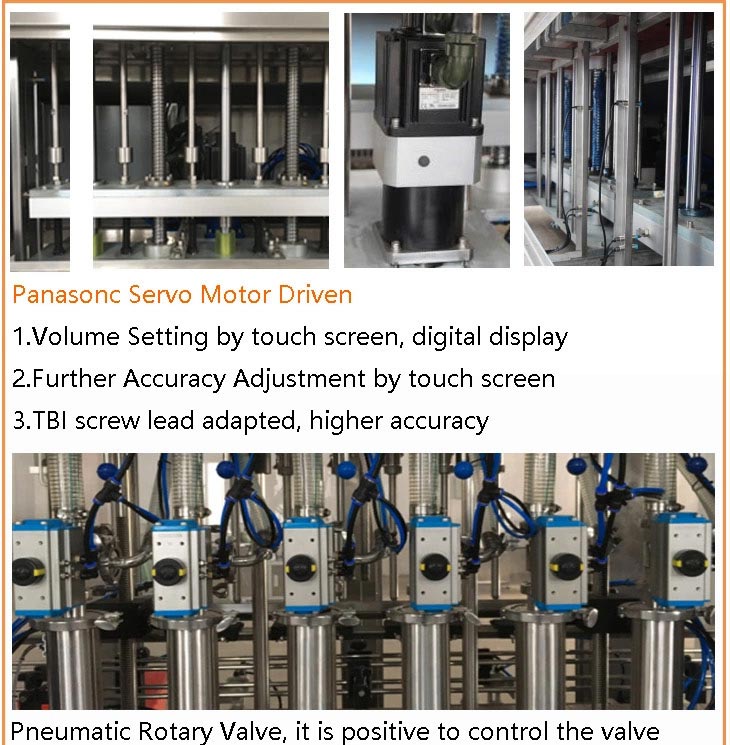

填充系統由伺服馬達驅動,確保了較高的填充精度,並且可以直接在觸控螢幕上輕鬆設定填充量。.

它廣泛應用於化妝品、食品、特殊化學品、製藥和個人護理行業。.

VK-PF型自動伺服馬達驅動活塞式填充機是VKPAK公司專門設計製造的,主要用於填充黏稠液體,如化妝品、日用化學產品,也可用於填充食品,如蜂蜜填充機、醬料填充機。.

包裝類型:瓶裝

包裝材料:木材

類型:灌裝機

狀態:全新

售後服務包括:線上支援、視訊技術支援、免費備件、現場安裝、調試和培訓

產地:中國上海

品牌名稱:VKPAK 便宜活塞式自動醬料填充機

電壓:220V/380V

應用領域:食品

重量:1200公斤

自動等級:自動

驅動類型:電動

尺寸(長*寬*高):2500*1400*2500毫米

名稱:廉價活塞式自動醬料填充機

接觸材質:316不銹鋼

控制方式:伺服馬達控制灌裝量

加工類型:灌裝液體,灌裝到瓶子中

填充容量:1000毫升-5000毫升和100毫升-1000毫升

機器名稱:醬料自動填充機

材質:不鏽鋼

產能:800-4200瓶/小時

填充精度:0.2%

VKPAK自動活塞填充機的不同類型

根據容量不同,醬料填充機有許多型號和類型,填充噴嘴數量從 1 個到 16 個不等,填充量從 100 克到 1000 克不等。.

自動活塞式填充機的主要結構

- 可選配20升至200公升頂部料斗,可選配帶加熱和攪拌系統的雙層夾套料斗。,

- 機器主體採用304不銹鋼製造

- 填充噴嘴,填充噴嘴是專為防滴漏醬料填充而設計的。

- 灌裝噴嘴由氣缸上下移動,伺服馬達上下移動(可選)。

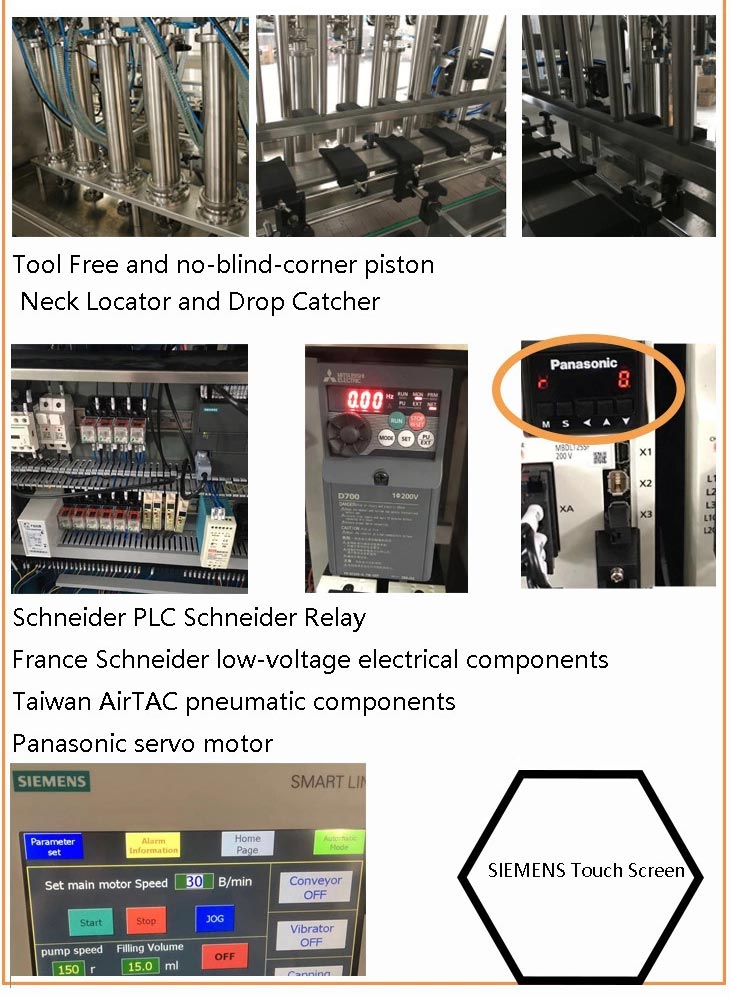

- PLC控制系統和HMI操作

- 專為蜂蜜製造的馬和閥門,與 CIP 系統連接馬。.

自動活塞式灌裝機的競爭優勢

自動活塞式填充機有很多優點。

- PLC控制,觸控螢幕操作。.

- 採用松下伺服馬達驅動,可透過人機介面自動調整填充量,例如,使用者想要填充 500 克醬料,只需輸入數字 500,機器就會自動調整。.

- 它採用活塞式容積充裝,充裝精度高。.

- 頂部採用雙層夾套加熱和混合罐。.

- 此自動醬料填充機還具備CIP系統功能,可與使用者的CIP系統連接。.

- 醬料填充馬是根據醬料的特性專門製作的,沒有死角,食品級。.

- 醬料填充機上的軟管或管道採用的是日本國際知名品牌Toyox的產品。.

- 專為輸送黏稠醬汁而設計的旋轉閥。.

技術參數

| 灌裝噴嘴 | 1-16噴嘴 |

| 生產能力 | 每小時 800-5000 瓶 |

| 填充量 | 100-500毫升,100毫升至1000毫升 |

| 力量 | 2000瓦,220伏特交流電 |

| 準確性 | ±0.1% |

| 驅動 | 松下伺服電機 |

| 介面 | 施耐德觸控螢幕 |

待灌裝產品:

1)熱灌裝(35~40℃),冷灌常溫

2) 比重:1.1~1.4 克/立方厘米

3)塗抹巧克力醬 • 蜂蜜 • 塗抹起司醬、糖蜜。.

瓶型:

1) PET 瓶 • 四分之一橫截面 • 容量 250 毫升 • 瓶頸 32 毫米。.

2) 玻璃罐和 PE、PET 罐 • 圓柱形橫截面 • 容量 200 ~ 350 毫升 • 瓶頸 45 毫米。.

填充公差: +/- 最大值 0.5%

細部圖

主要特點:

- 灌裝量易於調節,觸控螢幕自動調節,精準度高,速度穩定。.

- 線性填充系統易於調節,適用於多種不同類型的瓶子。

- 易於維護,無需特殊工具。.

- 無瓶,無灌裝,PLC自動控制

- 堵塞的填充噴嘴具有防滴漏、絲滑和自動切割黏稠液體的功能

- 精確填充量,誤差在±0.5-1%以內,並帶有總瓶數計數器。.

- 如果液體具有腐蝕性,則需採用特殊的密封件或軟管。.

- 如有需要,可使用潛水噴嘴從底部向上填充泡棉產品。

- 瓶口位置

VKPAK 自動活塞填充機是一款極為靈活的填充機,能夠快速、精確地填充任何黏稠液體。從散裝儲槽到活塞的物料輸送方式可配置為:使用液位感應浮球的緩衝槽、帶直接抽取的歧管或循環方式。 VKPAK 自動活塞填充機採用 304 不鏽鋼框架,可支援 1 至 16 個填充頭。 PLC 控制系統、觸控螢幕人機介面 (HMI)、食品級接觸部件、不銹鋼和陽極氧化鋁結構以及眾多其他功能均為標準配備。 VKPAK 自動活塞填充機旨在提高化妝品、食品服務、特殊化學品、製藥和個人護理行業任何生產線的效率。此外,還提供適用於衛生、危險、易燃和腐蝕性環境的附加選項。.

VKPAK 旨在提供最高的效率和便利的維護,憑藉直覺的工程設計、經濟實惠的價格、多功能性和有效性,為液體包裝系統提供最高品質的活塞式填充機。.

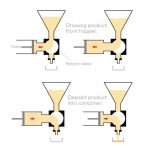

VKPAK活塞式填充機採用容積式填充原理,適用於多種不同產品。無論是半自動或全自動活塞式填充機,活塞都會後退,使供料系統中特定體積的產品進入汽缸。然後,隨著活塞返回氣缸,產品被從噴嘴推出並注入等待的容器中。.

雖然活塞式填充機可以處理各種黏度的產品,但對於黏度最高的物料以及含有大顆粒的物料來說,它們通常是理想的選擇。.

憑藉著各式各樣的高品質產品,客戶可以信賴其卓越的兼容性、耐用性和靈活性。這些機器旨在提高您的生產線效率。.

立即聯絡我們,找到您的解決方案!