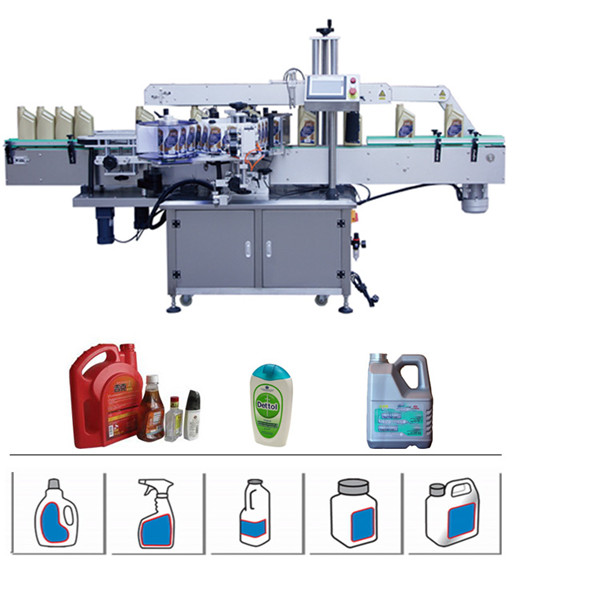

全自動自黏瓶貼標機

自動自黏瓶貼標機適用於多種瓶子的貼標。貼標時,瓶子會自動旋轉,使貼標裝置能夠施加壓力進行貼標。.

自動自黏瓶貼標機適用於多種瓶子的貼標。貼標時,瓶子會自動旋轉,使貼標裝置能夠施加壓力進行貼標。.

適用於醫藥、食品、飲料及化學工業。可用於塑膠、玻璃、金屬等圓形容器/瓶子。憑藉其創新設計,操作極為簡便,即使是原始人也能輕鬆使用。.

描述

簡而言之,貼標機用於自動將標籤貼到產品、容器、瓶子等物品上。手動貼標既費時又不夠專業。很久以前,在貼標機發明之前,人們只能手動在瓶子、罐子、容器等物品上貼標籤,這是一個既費時又費力的過程。但如今,貼標機已成為各行各業的福音。對於大批量產品包裝而言,除了使用貼標機之外,別無他法。因此,貼標機被廣泛應用於製藥、化妝品、快速消費品、食品飲料等眾多產業的包裝過程。.

包裝類型:瓶裝

包裝材料:紙

類型:貼標機,貼標機

狀態:全新

售後服務包括:線上支援、視訊技術支援、免費備件、現場安裝、調試和培訓,以及可派遣工程師到海外進行設備維護。

產地:中國上海

品牌名稱:VKPAK

電壓:220V 50/60HZ

應用領域:飲料、化工、食品、醫療

自動等級:自動

認證:ISO9001

驅動方式:機械式

尺寸(長*寬*高):1800毫米*1000毫米*1300毫米

功能:貼在瓶子上的貼紙標籤

貼標速度:20-100瓶/分鐘

馬達:伺服電機

材質:不鏽鋼

保固期:1年

標籤精度:1毫米

服務:全天候技術支援

包裝:長途運輸木箱

技術參數

| 型號/技術參數 | VK-DSL |

| 貼標速度(個/分鐘) | 40-100(與材質和標籤尺寸有關) |

| 標籤精度(毫米) | ±1.0mm(材質和標籤尺寸不計入) |

| 標籤尺寸(毫米) | (長)20-280毫米(高)30-144毫米 |

| 材料尺寸(毫米) | 直徑20-100毫米(高)40-200毫米 |

| 內徑(毫米) | φ76毫米 |

| 輥筒外徑(毫米) | 最大:Φ350mm |

| 機器尺寸(毫米) | (長)2000*(寬)850*(高)1450(毫米) |

| 電源 | 交流220伏 50赫茲/60赫茲 1500瓦 |

- 採用穩定適應型西門子PLC控制系統及松下伺服馬達驅動標籤,確保機器穩定運轉和標籤精度高,具有高性能和高效率的特性。.

- 操作簡單-觸控螢幕支援英語、西班牙語、法語、俄語以及其他任何語言。操作簡單,並且可以與其他機器連接,用於生產包裝線。.

- 高精度-精度為±0.5-1mm。應用範圍廣-廣泛適用於直徑25mm至120mm、高度25mm至300mm的瓶子。如需客製化高度10mm-150mm、長度15mm-300mm的瓶子,請與我們聯絡。.

- 高速-最高速度可達每分鐘 150 瓶,視標籤尺寸和瓶子尺寸而定。.

- 歐洲標準-此貼標機依CE標準製造,採用台灣技術。.

細部圖

瓶子貼標機的工作流程

- 手動將瓶子放在傳送帶上,或使用自動瓶子轉盤。

瓶子之間將以隔瓶器隔開,以保持瓶子之間的距離,從而確保工作穩定性。 - 所有動作均由PLC控制,自動偵測瓶子和標籤,並自動將標籤貼在瓶子的兩側。機器還具備無瓶不貼標功能,如果缺少標籤或沒有瓶子,則自動發出警告。

- 將標籤貼到瓶子上後,貼標機將標籤貼在瓶子上,使標籤牢固地固定在瓶子上。.

- 然後瓶子進入下一工序。

主要特點:

- 採用步進伺服馬達、PLC控制系統、彩色觸控螢幕顯示。.

- 採用日本光電感應器自動偵測並檢查標籤長度。

- 配備標籤不足、標籤破損和缺少色度膠帶的警告裝置。.

- 標籤定位準確,速度快,貼標精度高。.

- 自動檢測,無需容器,無需標籤。.

- 機身採用不銹鋼製造,完全符合GMP要求。

- 它可以與編碼/噴墨印表機一起安裝(可選)。.

這款自黏標籤機全自動、直立、線性運作。這款多包裝機型擁有許多便捷易用的功能。它是為扁平、橢圓形、方形和圓形容器貼標(正面、背面或側面)的理想設備。這款堅固耐用的機器每分鐘最多可貼100張標籤,具體產量取決於產品的形狀、尺寸和標籤大小。它還配備了自動同步系統,可將產品與頂部輸送帶對齊。該設備的另一個亮點是先進的微處理器控制標籤分發系統,以及最新的標籤和產品感測系統。這款多功能、高速的標籤機高效、精準、經久耐用,旨在滿足現代包裝生產線用戶的多樣化需求。此機器操作簡便,易於調節,所需工具和更換零件極少。它還可以配備特殊的進料螺旋和料斗系統,以確保瓶子在輸送帶上正確對齊,從而實現精準貼標。此外,該機型還配備了獨特的單點同步速度控制系統。此外,內建的預設標籤長度偵測系統無需手動輸入和儲存標籤長度數據,也無需每次更換標籤尺寸或重新啟動設備時都進行讀取。這節省了您的時間,減少了機器停機時間,並提高了生產效率。該設備還可選配由堅固玻璃或壓克力製成的安全櫃。該設備可特別設計用於在扁平瓶身和瓶身上貼上單面標籤,以及在圓形瓶身上貼環繞式標籤。此外,它還具備目前市場上標準機型的所有基本功能。.