Automaatne orientatsioonipositsiooni märgistusmasin

VKPAK kleebiste märgistamise masina tootmine Shanghais. Pudelile orienteeritud märgistusmasin on mõeldud ümmarguse pudeli jaoks ja vähendab käsitsi märgistamise probleeme.

Klient säästab käsitsikulusid ja kiirus on palju suurem. Seda kasutatakse farmaatsia-, keemia-, toiduainetööstuses jne.

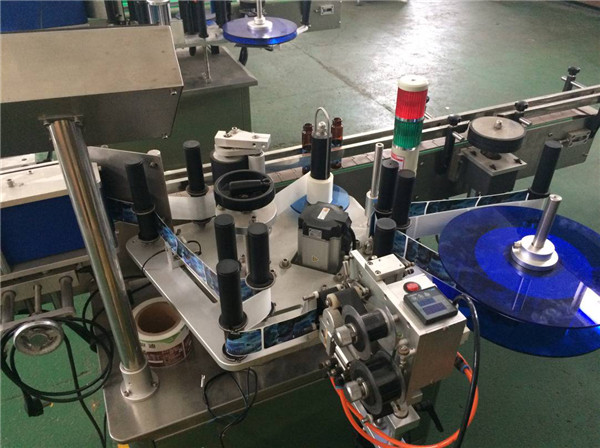

VKPAK on professionaalne tehas igasuguste märgistusmasinate tootmisel (kleebiste märgistamise masin , liimimärgistusmasin , varrukate märgistamise masin). Pudelitele orienteeritud sildistusmasin on mõeldud kleebiste/liimitavate siltide jaoks, sobib ümmarguste pudelite, plekkpurkide ja purkide jaoks. Kleebisega pudelitele orienteeritud sildistusmasin, automaatselt positsioneeriv kooniliste pudelite sildistusmasin.

Kirjeldus

- Pudelitele orienteeritud märgistusmasinat juhib servomootor (sildi täpsus on 1 mm), see sobib igat tüüpi ümmarguste anumate jaoks. .

- Kõik märgistusmasina elektrilised osad on valmistatud Taiwanis või Jaapanis

- Kolmepunktiline kinnitusmehhanism võimaldab ümmarguste pudelite märgistamist suure täpsusega

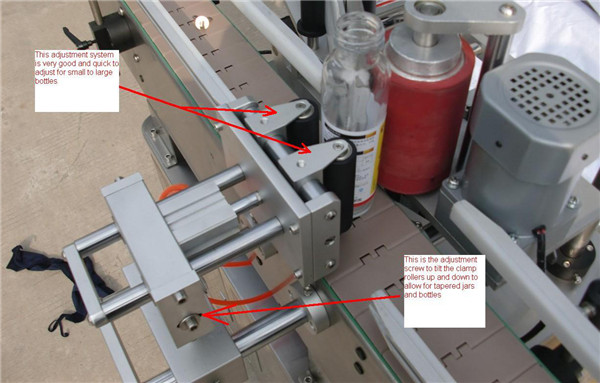

- Pneumaatiline ümberpööratav jaam mitmekülgse pudeli läbimõõdu jaoks

Pakendi tüüp: Pudelid

Pakkematerjal: puit

Tüüp: Märgistusmasin

Seisukord: Uus

Pakutav müügijärgne teenindus: veebitugi, videotehniline tugi, tasuta varuosad, kohapealne paigaldus, kasutuselevõtt ja koolitus, kohapealne hooldus ja remont

Päritolukoht: Shanghai, Hiina

Kaubamärk: VKPAK

Pinge: 220v 50Hz

Kasutamine: joogid, keemia, toit, meditsiin

Kaal: 300 kg

Automaatne hinne: Automaatne

Sertifitseerimine: ISO9000, CE

Mõõtmed (P * L * K): 2000 mm * 850 mm * 1450 mm

Kohaldatavad tööstusharud: hotellid, rõivakauplused, ehitusmaterjalide kauplused, tootmistehas, masinaehitustöökojad, toidu- ja joogitehased, talud, restoranid, jaemüük, toidupood, trükikojad, ehitustööd, toidu- ja joogikauplused, reklaamifirmad

Nimi: orientatsioonipositsiooni märgistamise masin

mudel: VK-RPL

Märgistamise kiirus (tk/min): 30-50 (olenevalt materjalist ja sildi suurusest)

Märgistuse täpsus (mm): ±1,0 mm (materjali ja etiketi suurusi ei arvestata)

Sildi suurus (mm): (P) 20–300 mm (K) 30–180 mm

Materjali mõõtmed (mm): 20–120 mm (K) 40–200 mm

Rulli sisekülg (mm): 76 mm

Rulli välisläbimõõt (mm): Max: 350 mm

Masina suurus (mm): (P) 2000 * (L) 850 * (K) 1450 (mm)

Toiteallikas: AC220V 50Hz/60Hz 1500W

Tehniline parameeter

| Nimi | Pudelile orienteeritud märgistusmasin |

| Märgistamise kiirus | 20–40 tk/min (sõltuvalt sildi pikkusest ja pudeli paksusest) |

| Objekti kõrgus | 30–200 mm |

| Objekti paksus | 30–90 mm |

| Sildi kõrgus | 15–140 mm |

| Sildi pikkus | 25–300 mm |

| Sildirulli siseläbimõõt | 76 mm |

| Sildirulli välisläbimõõt | 380 mm |

| Märgistuse täpsus | ±0,5 mm |

| Toiteallikas | 220 V 50/60 Hz 0,8 kW |

| Printeri gaasitarve | 5 kg/cm² |

| Märgistusmasina suurus | 2000 (P) × 1000 (L) × 1250 (K) mm |

| Märgistusmasina kaal | 150 kg |

- Sobib ümarate pudelite fikseeritud punkti ja asukoha märgistamiseks.

- Kasutage kummist rataste diferentsiaalvahe mehhanismi, inverteri astmevaba kiiruse muutmist, mis on jaotatud mis tahes vahekauguseks. Toodete vahetamisel pole vaja spetsifikatsioone muuta.

- Kasutage imporditud tuntud kaubamärgi servomootorit, mis tagab suure kiiruse, täpsuse ja stabiilsuse.

- Kasutades silindri positsioneerimist, kiiret toimimist ja rakendatavust laiale tootespetsifikatsioonide valikule.

- Kummist rattad veerevad siltidel, pikk kasutusiga. Positsioneerimismärgistus on ülitäpne märgistamine.

- Märgistamise täpsus ± 0,5 mm.

Konfiguratsiooni osad

| Märgistusmasina (VK-RPL) konfiguratsiooni osad | |

| Kirjeldus | Märkus |

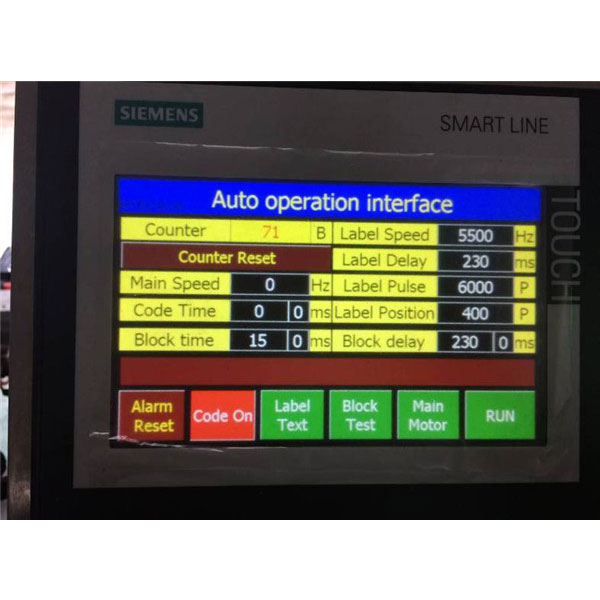

| PLC | Siemens |

| Puutetundlik ekraan | Siemens |

| Muundur | Delta valmistatud Taiwanis |

| DC24V elektriallikas | Delta valmistatud Taiwanis |

| Sildianduri kontrollimine | Keyence (valmistatud Jaapanis) |

| Pudelianduri kontrollimine | Keyence Valmistatud Jaapanis |

| Optiline | Keyence Valmistatud Jaapanis |

| PANASONIC MOOTOR JA JUHT | Valmistatud Jaapanis |

| LÜLITI | SCHNIDER PRANTSUSMAA |

| Avariilüliti | SCHNIDER PRANTSUSMAA |

Detailsed pildid

Lindi kodeerimismasin (trüki etiketile EXP MFG BATCH)

- 1. Lai valik rakendusi, et rahuldada silindrite märgistamise läbimõõduga 10–100 mm

- 2. Märgistamise täpsus on kõrge, sildi otsast lõpuni kohalik hälve ≤ ± 0,5 mm

- 3. Nutikas ekstrusiooniseadme materjal, lihtsalt pane toorik paika ja märgistus täidetakse automaatselt

- 4. Kaardi asukoha reguleerimine, lihtne tooriku märgistamise lüliti

- 5. Hammasrihma veojõud, mis parandab oluliselt mehaanilist stabiilsust

Peamised omadused:

- 1. Puuteekraan ja PLC juhtimine

- 2. Umbes 30 mäluretsepti parameetrite märgistamiseks, mis hõlbustavad pudeli suuruse muutmist.

- 3. Madala või puuduva sildi tuvastamine.

- 4. Sünkroniseeritud kiiruse valik

- 5. Servomootori ajam suure täpsuse ja suure kiiruse tagamiseks

- 6. Pudelit pole, silti pole.

- 7. Kuumfooliumi kodeerimismasina kinnitamine, mis saab etiketile printida EXP MFG BATCH

Märgistusmasinaid kasutatakse laialdaselt toidu-, farmaatsia- ja igapäevases keemiatööstuses erinevate etikettide jaoks. VKPAK pakub ümarate pudelite märgistusmasinaid ümarate, kooniliste ja hulknurksete pudelite täpseks orienteerimiseks.