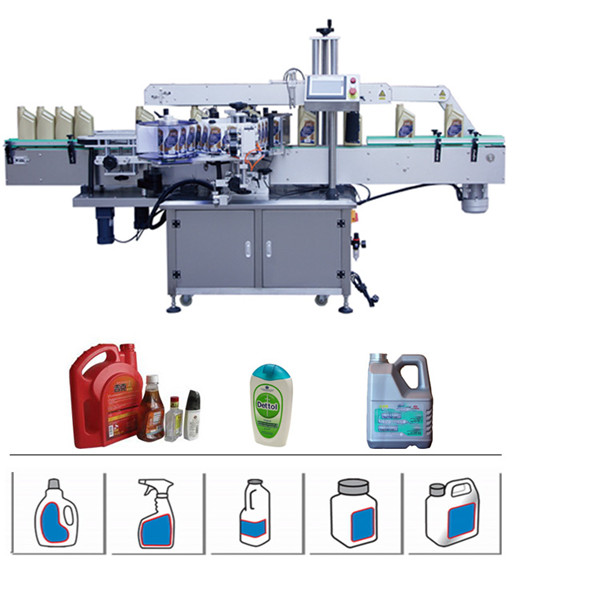

Automaatne isekleepuv pudelimärgistusmasin

Automaatne isekleepuv pudelimärgistusmasin sobib paljude erinevate pudelimärgistuste tegemiseks. Märgistamise ajal pöörleb pudel automaatselt, et märgistusseade saaks märgistamiseks survet avaldada.

Automaatne isekleepuv pudelimärgistusmasin sobib paljude erinevate pudelimärgistuste tegemiseks. Märgistamise ajal pöörleb pudel automaatselt, et märgistusseade saaks märgistamiseks survet avaldada.

Sobib meditsiini-, toidu-, joogi- ja keemiatööstusele. Kasutatav plast-, klaas-, metall- ja muude ümmarguste anumate/pudelite jaoks. Tänu uuenduslikule disainile on selle kasutamine nii lihtne, et isegi ürginimene saab sellega hakkama.

Kirjeldus

Põhimõtteliselt kasutatakse sildistusmasinat toodete, konteinerite, pudelite jms automaatseks kleepimiseks. Käsitsi sildistamine võib olla aeganõudev ja ebaprofessionaalne viis toote pakkimiseks. Kaua aega tagasi, kui sildistusmasinaid polnud veel leiutatud, tehti pudelite, purkide, konteinerite jms sildistamine käsitsi, mis oli pikk ja aeganõudev protsess. Kuid nüüd on sildistusmasinatest saanud tööstusharude õnnistus. Toodete lahtise pakendamise puhul pole muud viisi toodete märgistamiseks kui sildistusmasina kasutamine. Seega kasutatakse sildistusmasinat paljudes tööstusharudes, näiteks farmaatsia-, kosmeetika-, kiirtarbekaupade, toidu- ja joogitööstuses jne.

Pakendi tüüp: Pudelid

Pakkematerjal: paber

Tüüp: Märgistusmasin, Märgistusmasin

Seisukord: Uus

Pakutav müügijärgne teenindus: veebitugi, videotehniline tugi, tasuta varuosad, paigaldus, kasutuselevõtt ja koolitus, insenerid on masinate hooldamiseks välismaal saadaval

Päritolukoht: Shanghai, Hiina

Kaubamärk: VKPAK

Pinge: 220V 50/60Hz

Kasutamine: joogid, keemia, toit, meditsiin

Automaatne hinne: Automaatne

Sertifitseerimine: ISO9001

Ajami tüüp: mehaaniline

Mõõtmed (P * L * K): 1800 mm * 1000 mm * 1300 mm

Funktsioon: kleebis pudelil

Märgistamise kiirus: 20–100 pudelit minutis

Mootor: servomootor

Materjal: Roostevaba teras

garantii: 1 aasta

Märgistuse täpsus: 1 mm

Teenindus: 24/7 tehniline tugi

pakkimine: pikamaa puidust ümbris

Tehniline parameeter

| Mudel / tehnilised parameetrid | VK-DSL |

| Märgistamise kiirus (tk/min) | 40–100 (olenevalt materjalist ja sildi suurusest) |

| Märgistamise täpsus (mm) | ±1,0 mm (materjali ja etiketi suurusi ei arvestata) |

| Sildi suurus (mm) | (P) 20–280 mm (K) 30–144 mm |

| Materjali suurus (mm) | Φ20–φ100 mm (kõrgus) 40–200 mm |

| Rulli sisekülg (mm) | φ76mm |

| Rulli välisläbimõõt (mm) | Maks: Φ350mm |

| Masina suurus (mm) | (P) 2000 * (L) 850 * (K) 1450 (mm) |

| Toiteallikas | Vahelduvvool 220V 50Hz/60Hz 1500W |

- Stabiilselt kohanduv Siemensi PLC juhtimine ja Panasonicu servomootoriga juhitav etikett masina stabiilseks tööks ja etiketi täpsuse tagamiseks. See on suure jõudlusega ja suure tõhususega.

- Lihtne kasutada – puuteekraan on inglise, hispaania, prantsuse, vene ja mis tahes muus keeles. Seda on lihtne kasutada ja seda saab ühendada teiste pakkimisliini tootmismasinatega.

- Suur täpsus – täpsus vahemikus +/-0,5–1 mm. Lai rakendusulatus – sobib laialdaselt pudelitele läbimõõduga 25–120 mm ja kõrgusega 25–300 mm. Kui soovite kohandatud kõrgust 10–150 mm ja pikkust 15–300 mm, siis palun võtke meiega ühendust.

- Suur kiirus - maksimaalne kiirus võib ulatuda 150 pudelini minutis, olenevalt sildi ja pudeli suurusest.

- Euroopa standard - märgistusmasin on valmistatud vastavalt CE-standardile, Taiwani tehnoloogiale.

Detailsed pildid

Pudelite märgistamise masina tööprotsess

- Pange pudelid käsitsi konveierile või automaatse pudelite pöördlaua abil

Ja pudelid eraldatakse pudelieraldajaga, et hoida iga pudeli kaugus töö stabiilsuse tagamiseks - Kõik toimingud on PLC juhtimisel, pudel ja sildid tuvastatakse automaatselt, sildid kantakse automaatselt pudelite mõlemale küljele. Masinal on funktsioon, pudelit pole, sildistust pole, automaatne hoiatus sildi puudumise või puudumise korral.

- Pärast pudelitele etikettide kleepimist kleebib etiketi kleepimisseade etiketid pudelitele kinnitamiseks.

- Seejärel läheb pudel järgmisele töötlusele

Peamised omadused:

- Võtab vastu astmelise servomootori, PLC juhtimissüsteemi ja värvilise puutetundliku ekraani.

- Võtke Jaapani fotosensor kasutusele, et automaatselt tuvastada ja kontrollida siltide pikkust

- Varustatud hoiatusseadmega ebapiisavate, katkiste ja kromaatiliste lintide puudumise kohta.

- Täpne sildi asend, kiire kiirus ja kõrge märgistamise täpsus.

- Automaatne tuvastamine, konteinerit pole, märgistust pole.

- Masina korpus on valmistatud roostevabast terasest, mis vastab täielikult GMP nõuetele

- Selle saab paigaldada kodeerimis-/tindiprinteriga (valikuline).

Isekleepuvate kleebiste kleepimismasin on täisautomaatne, vertikaalne ja lineaarne. Sellel mitmikpakendil on mitmeid kasutajasõbralikke funktsioone. See on kõige sobivam seade esi-, taga- või külgmiste etikettide paigaldamiseks lamedatele, ovaalsetele, ruudukujulistele ja ümaratele anumatele. See vastupidav masin suudab pakkuda maksimaalselt 100 etiketti minutis; olenevalt toodete kujust ja suurusest ning etiketi suurusest. See sisaldab ka automaatset ja sünkroniseeritud süsteemi toote joondamiseks ülemise hoidelindi süsteemiga. Selle seadme teine suurepärane element on täiustatud mikroprotsessoriga juhitav etikettide väljastussüsteem; koos uusima etikettide ja toodete tuvastamise süsteemiga. See mitmeotstarbeline, kiire sildistusmasin on tõhus, täpne ja kauakestev. See on loodud vastama tänapäevaste pakendusliinide kasutajate mitmekesistele vajadustele. See lihtsalt kasutatav ja hõlpsasti reguleeritav masin vajab minimaalselt tööriistu ja varuosade vahetamist. See saab spetsiaalselt konstrueerida söötmisussi ja taskusüsteemiga, et tagada pudelite õige joondamine konveieril täpseks sildistamiseks. See mudel sisaldab isegi eksklusiivset ühepunktilist sünkroniseeritud kiiruse juhtimissüsteemi. Lisaks võimaldab sisseehitatud ja eelseadistatud etiketi pikkuse tuvastamise süsteem vältida etiketi pikkuse andmete käsitsi sisestamist ja mällu salvestamist ning neid iga kord etiketi suuruse muutmiseks ja seadme taaskäivitamiseks hankida. See säästab teie aega, hoiab ära masina seisakute tekkimise ja suurendab tootlikkust. See on saadaval ka valikulise turvakapiga, mis on valmistatud vastupidavast klaasist või akrüülist. See seade saab olla spetsiaalselt konstrueeritud ühepoolsete etikettide kleepimiseks lamedatele pudelitele ja korpustele ning ümmarguste etikettide mähkimiseks ümmargustele pudelitele. Lisaks sisaldab see kõiki standardmudeli olulisi omadusi vastavalt praegusele turule.