Automaatne kolbviskoosse vedeliku täitmise masin

Rakendus:

Seda tüüpi kolbtäiteseade sobib kõige paremini viskoossete toodete jaoks, mis on pasta, poolpasta või suurte osakestega tükilised. Need kolbtäiteseadmed on ehitatud vastama toidukvaliteedi standarditele ja sobivad ka mitmesuguste keemiliste rakenduste jaoks.

Näited:

Rasked kastmed, salsad, salatikastmed, kosmeetilised kreemid, rasked šampoonid, geelid ja palsamid, pastapõhised puhastusvahendid ja vahad, liimid, rasked õlid ja määrdeained.

Eelised:

See odavam tavapärane tehnoloogia on enamiku kasutajate jaoks kergesti mõistetav. Kiire täitmiskiirus on saavutatav ka üsna paksude toodetega. Hoiatus: see tehnoloogia on servomootoriga positiivse nihkega täiteainete tulekuga peaaegu vananenud.

Kirjeldus

See täitemasin on kolbtüüpi täitemasin, mis sobib erineva viskoossusega vedelike täitmiseks. Masin on valmistatud reas oleva konstruktsiooniga ja täitepeade arvu saab vastavalt tootmisvõimsusele eritellimusel valmistada, näiteks 6/8/10/12/16/20 pead.

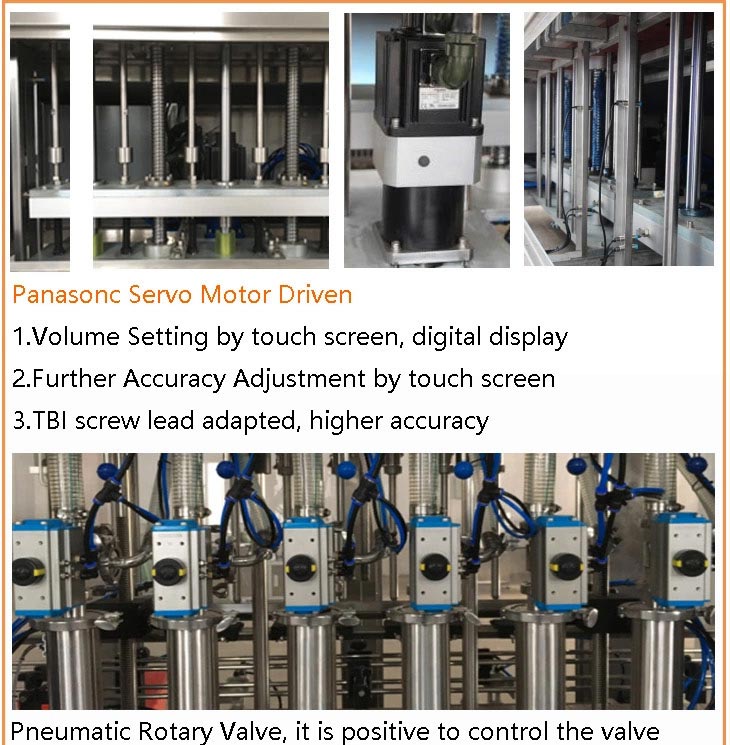

Täitesüsteemi juhib servomootor, mis tagab kõrge täitmise täpsuse, samuti on täitemahtu puutetundlikul ekraanil lihtne seadistada.

Seda kasutatakse laialdaselt kosmeetika-, toidu-, erikeemia-, farmaatsia- ja isikuhooldustööstuses.

VK-PF automaatne servomootoriga kolbtäitmismasin on spetsiaalselt VKPAKi poolt projekteeritud ja toodetud. Seda kasutatakse peamiselt viskoossete vedelike, näiteks kosmeetikatoodete, igapäevaste keemiatoodete, aga ka toiduainete, näiteks mee täitmise masina ja kastme täitmise masina täitmiseks.

Pakendi tüüp: Pudelid

Pakkematerjal: puit

Tüüp: Täitmismasin

Seisukord: Uus

Pakutav müügijärgne teenindus: veebitugi, videotehniline tugi, tasuta varuosad, kohapealne paigaldus, kasutuselevõtt ja koolitus

Päritolukoht: Shanghai, Hiina

Brändi nimi: VKPAK Odav kolbautomaatne kastme täitmise masin

Pinge: 220V/380V

Rakendus: toit

Kaal: 1200 kg

Automaatne hinne: Automaatne

Ajami tüüp: elektriline

Mõõtmed (P * L * K): 2500 * 1400 * 2500 mm

Nimi: Odav kolbautomaatne kastme täitmise masin

Kontaktmaterjal: 316SS

Juhtimine: Servomootori juhtimise täitemaht

Töötlemistüübid: vedeliku täitmine pudelisse

Täitemaht: 1000ml-5000ml ja 100ml-1000ml

Masina nimi: automaatne kastme täitmise masin

Materjal: Roostevaba teras

Mahutavus: 800–4200 BPH

Täitmise täpsus: 0,2%

Erinevat tüüpi VKPAK automaatsed kolbtäitmismasinad

Kastmetäitemasinate baasil on palju mudeleid ja tüüpe, erineva mahutavusega, täitedüüside arv on ühest peast kuni 16 peani ja täitemaht on 100 g kuni 1000 g.

Automaatse kolbtäiteseadme põhistruktuur

- 20L kuni 200L ülemine punker valiku jaoks, topeltjope punker kütte- ja segamissüsteemiga valiku jaoks,

- Masina põhiosa on valmistatud 304SS-st

- Täiteotsikud, täiteotsikud on spetsiaalselt loodud tilkumisvastase kastme täitmiseks

- Täitedüüsid liiguvad üles ja alla õhusilindri abil ning servomootor liigub valikuliselt üles ja alla

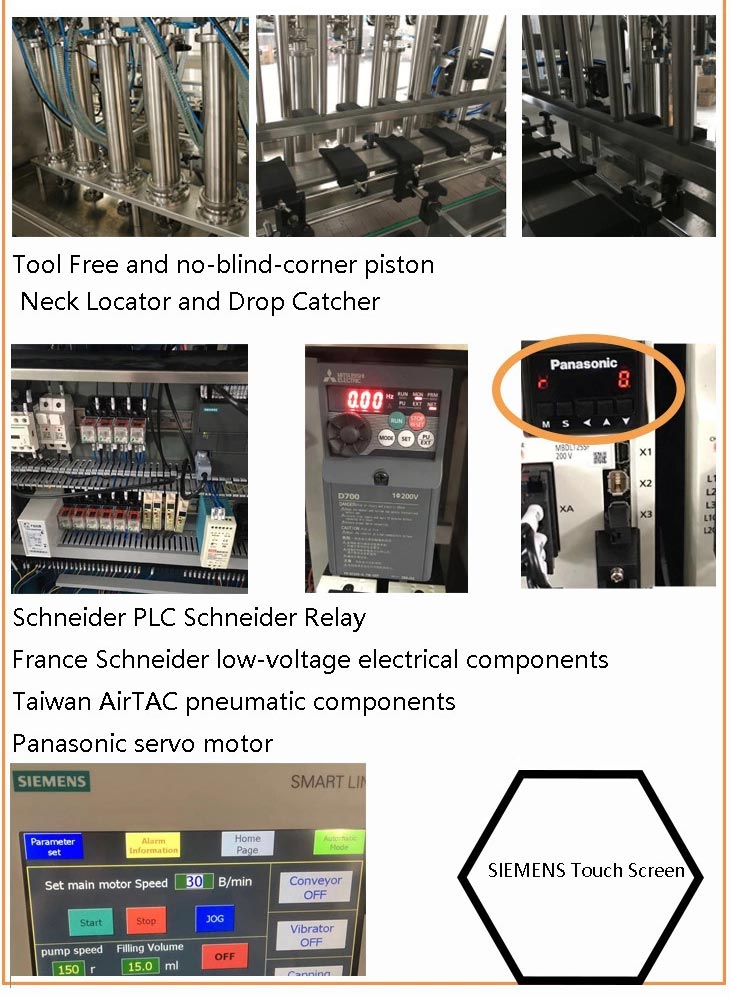

- PLC juhtimissüsteem ja HMI töö

- Spetsiaalselt mee jaoks valmistatud hobune ja ventiil, CIP-süsteemiga ühenduv hobune.

Automaatse kolbtäiteseadme konkurentsieelis

Automaatsel kolbtäitmismasinal on palju eeliseid

- PLC juhtimine, puutetundliku ekraani kasutamine.

- Panasonicu servomootoriga juhitav, täitesuuruse automaatne reguleerimine HMI-l, nt. Kasutajad soovivad täita 500 g kastet, sisestavad lihtsalt numbri 500, seejärel reguleerib masin automaatselt.

- See on kolvi abil mahuline, kõrge täitmise täpsusega.

- Topeltümbrisega kütte- ja segamispaakidega.

- Automaatsel kastmetäitmismasinal võib olla ka CIP-süsteemi funktsioon, mis ühendab kasutaja CIP-süsteemi.

- Kastmetäidise hobune on spetsiaalselt valmistatud vastavalt kastme olemusele, surnud nurka pole, toidukvaliteediga.

- Kastmetäite pehmed torud või voolikud on Jaapanist pärit maailmabrändi Toyox omad.

- Spetsiaalselt valmistatud pöördventiil viskoosse kastme ülekandmiseks.

Tehniline parameeter

| Täitepihustid | 1-16Püüdurid |

| Tootmisvõimsus | 800–5000 pudelit tunnis |

| Täitemaht | 100–500 ml, 100 ml kuni 1000 ml |

| Võimsus | 2000 W, 220 V vahelduvvool |

| Täpsus | ±0,1% |

| Sõidetud | Panasonicu servomootor |

| Liidese | Schneideri puutetundlik ekraan |

Täitmiseks mõeldud tooted:

1) kuumtäidis (35–40 ℃), külmtäidis normaaltemperatuuril

2) Suhteline tihedus: 1,1–1,4 g/cm3

3) Šokolaadipasta määrimine • Mesi • Juustupasta, melass.

Pudeli tüüp:

1) PET-pudel • Kvadrantne ristlõige • Maht 250 ml • kael 32 mm.

2) Klaaspurgid ja PE-, PET-purgid • Silindrilise ristlõikega • Maht 200–350 ml • Kael 45 mm.

Täitmistolerantsid: +/- max 0,5%

Detailsed pildid

Peamised omadused:

- Täitemahu lihtne reguleerida, automaatne reguleerimine puutetundliku ekraani abil, kõrge täpsus ja stabiilne kiirus.

- Lineaarset tüüpi täitesüsteemi on lihtne reguleerida paljude erinevat tüüpi pudelite jaoks

- Lihtne hooldada, spetsiaalseid tööriistu pole vaja.

- Pudelit pole, täitmist pole, automaatne PLC-juhtimine

- Ummistunud täitedüüsid on tilgavastased, siidist ja automaatselt lõigatud viskoossed vedelikud

- Täpne täitemaht, ±0,5–1% piires ja pudelite koguarvu loendur.

- Kui vedelik on söövitav, kasutatakse spetsiaalseid tihendeid või voolikuid.

- Vajadusel sukeldumisotsikud vahutavate toodete alt ülespoole täitmiseks

- Pudeli suu võib paikneda

VKPAK automaatne kolbtäiteseade on äärmiselt paindlik täiteseade, mis on võimeline täpselt ja kiiresti täitma mis tahes viskoosseid vedelikke. Toote edastamist teie mahutist kolbideni saab konfigureerida puhverpaagiga, mis kasutab tasemeanduriga ujukit, otsevooluga kollektori või retsirkulatsioonimeetodeid. VKPAK automaatne kolbtäiteseade on valmistatud 304 roostevabast terasest raamiga ja suudab toetada 1 kuni 16 täitepead. PLC juhtnupud, puutetundliku ekraaniga HMI, toiduainetega kokkupuutuvad osad, roostevabast terasest ja anodeeritud alumiiniumist konstruktsioon ning palju muid funktsioone on standardvarustuses. VKPAK automaatsed kolbtäiteseadmed on loodud suurendama tõhusust mis tahes tootmisliinil, mida kasutatakse kosmeetika-, toitlustus-, erikeemia-, farmaatsia- ja isikuhooldustööstuses. Lisavõimalused on saadaval sanitaarsete, ohtlike, tuleohtlike ja söövitavate keskkondade jaoks.

VKPAK, mis on loodud maksimaalse efektiivsuse ja hõlpsa hoolduse tagamiseks, tugineb vedelike pakendamise süsteemide jaoks kõrgeima kvaliteediga kolbtäitmismasinate pakkumisel intuitiivsele inseneritööle, taskukohasusele, mitmekülgsusele ja tõhususele.

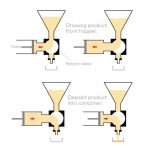

VKPAKi kolbtäitmismasinad kasutavad laia valiku erinevate toodete jaoks mahulist täitmise põhimõtet. Nii poolautomaatsete kui ka automaatsete kolbtäitmismasinate puhul tõmbab kolb tagasi, et lasta toitesüsteemist teatud kogusel toodet silindrisse siseneda. Seejärel surutakse toode otsikust välja ja ootavatesse anumatesse, kui kolb silindrisse naaseb.

Kuigi kolbtäitevedelikud sobivad laia viskoossusvahemikuga, on need sageli ideaalne valik nii kõrgeima viskoossusega toodete kui ka suurte osakestega toodete jaoks.

Laia valiku kvaliteetsete toodetega saavad kliendid loota maksimaalsele ühilduvusele, vastupidavusele ja paindlikkusele. Need masinad on loodud teie tootmisliini tõhusaks muutmiseks.

Võtke meiega ühendust, et leida oma lahendus juba täna!