Mesin Pengisian Botol Pompa Peristaltik Rotary Otomatis

Cara Kerjanya:

Pompa peristaltik melakukan kontak intermiten hanya pada bagian luar tabung bedah (produk) sehingga produk hanya menyentuh bagian dalam tabung. Komputer utama pengisi secara independen melacak putaran kepala pompa peristaltik # sehingga mengetahui secara tepat berapa banyak produk yang telah disalurkan. Ketika volume pengisian target tercapai, pompa berhenti dan sisa cairan produk tidak menetes keluar karena aksi pipet. Komputer menyimpan semua parameter pengisian dalam memori untuk pergantian yang cepat.

Aplikasi:

Dirancang khusus untuk pengisian bernilai tinggi, volume kecil, dan akurasi sangat tinggi. Cocok untuk produk berbasis air dan produk dengan viskositas rendah lainnya.

Contoh:

Sediaan farmasi, wewangian, minyak esensial, reagen, tinta, pewarna, dan bahan kimia khusus.

Keuntungan:

Jalur fluida sekali pakai; mudah dibersihkan dan menghilangkan masalah kontaminasi silang. Akurasi 0,5% dapat dicapai untuk volume pengisian kurang dari 1 ml.

Keterangan

Pompa peristaltik presisi tinggi untuk pengisian, pengukuran akurat, dapat disetel, bersih, perawatan mudah, pengoperasian mudah, tanpa botol, tanpa pengisian, tanpa botol, tanpa sumbat, dan tanpa penutup sumbat. Permukaan kerja dilindungi oleh baja tahan karat 304 berkualitas tinggi, dan bagian yang bersentuhan dengan cairan terbuat dari baja tahan karat 316L, sehingga mesin ini memenuhi persyaratan GMP.

Mesin ini berlaku untuk industri farmasi dalam proses pengisian dan penyegelan botol cairan, dll. Struktur pesawat masuk akal, secara otomatis mengurai botol, pengisian dan colokan, colokan, penutup, penutup, tutup ulir, pengindeks CAM presisi tinggi untuk posisi grafik yang seragam, tidak ada jarak bebas, akurasi posisi;

Bahan Kemasan: Kayu

Tipe: Mesin Pengisi

Kondisi: Baru

Tempat Asal: Shanghai, Tiongkok

Nama Merek: VKPAK Mesin pengisian cairan botol semprot pompa peristaltik

Nomor Model: VK-MFC Mesin pengisian cairan botol semprot pompa peristaltik

Daya: 2000W

Tegangan: 220V 50HZ

Aplikasi: Minuman, Kimia, Makanan, Medis

Berat: 400KG

Kelas Otomatis: Otomatis

Sertifikasi: ISO9001 CE GMP

Dimensi (P*L*T): 3000mm*1300mm*1700mm

Nama: Mesin pengisian cairan botol semprot pompa peristaltik

Model: VK-MFC Mesin pengisian cairan botol semprot pompa peristaltik

Fungsi: Mesin pengisian cairan, stopper dan capping

Volume pengisian: 3ml-30ml dan 30ml-100ml dan 100ml-500ml

Kontrol: PLC dan Layar Sentuh

Cocok: Vial, parfum, cairan oral, E-liquid, tetes mata

Bahan: Baja Tahan Karat 304/316

Garansi: 12 Bulan

Kapasitas: 20-80 botol/menit

Jenis Pemrosesan: Pengisian Tekanan Normal

Layanan Purnajual yang Disediakan: Teknisi tersedia untuk melayani mesin di luar negeri

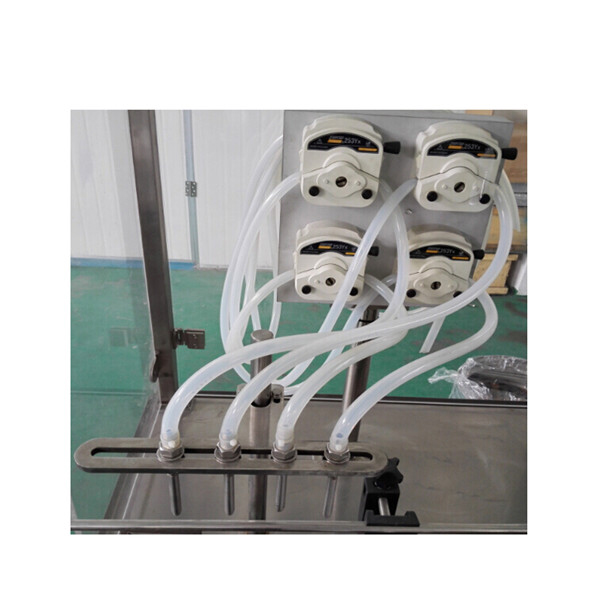

Mesin ini terutama terdiri dari pelindung debu, sabuk pengangkut, kotak listrik, rak, tempat penampungan penyumbat, tempat penampungan penutup, meja putar, dan pompa peristaltik, dan lain-lain.

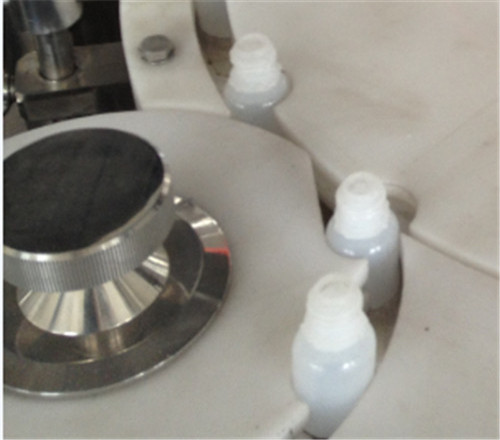

Siapkan botol, sumbat dalam, tutup luar, dan cairan yang memadai; jalur hopper osilasi harus diisi dengan sumbat dalam dan tutup luar, dan ditempatkan di stasiun penutup luar. Botol dipasok dengan mesin botol atau secara manual, dipindahkan dengan sabuk konveyor; botol yang dipindahkan dengan sabuk konveyor harus dipindahkan dengan pelat penggerak dalam botol ke pelat bundar pemosisian. Dua botol ditarik masuk setiap putaran pelat penggerak dalam botol; kemudian, botol-botol dipindahkan dengan memposisikan pelat bundar secara berkala ke stasiun pengisian, penutupan, penggantung, dan penutupan.

Parameter Teknis

| Kapasitas produksi | 20-80 botol/menit |

| Botol yang diaplikasikan | 2 botol 30ml |

| Nosel pengisian | 2 nozel |

| Akurasi pengisian | ≤ ±1% |

| Tekan nozel penutup | 1 nozel |

| Tingkat pembatasan | 99% atau lebih (tergantung pada karakteristik steker, penyesuaian yang sesuai) |

| Kontrol kecepatan | kontrol frekuensi |

| Ukuran botol | Lebih dari 10 mm |

| Sumber daya listrik | 380V 50Hz, atau disesuaikan |

| Kekuatan | 2 kW |

| Pasokan udara | 0,3~04kFg/cm2 |

| Konsumsi gas | 10~15m3/jam |

| Dimensi keseluruhan | Ukuran 2600*1300*1600 mm |

Konfigurasi utama:

Mesa, di sekeliling pelat samping terbuat dari baja tahan karat 304 berkualitas tinggi atau bahan produksi lain yang telah mendapat persetujuan FDA, dan bagian kontrak bahan untuk baja tahan karat kualitas 316L.

| Bahan nosel pengisi | Baja tahan karat SUS 316L |

| Jenis pengisian | Pompa peristaltik |

| Pengindeksan CAM | Shandongzhucheng |

| Inverternya | Mitsubishi Jepang |

| PLC | Siemens |

| Layar sentuh | Siemens |

| Motor utama | ABB |

| peralatan tegangan rendah | Schneider |

| Motor servo | Taiwan TECO |

Gambar Detail

Mekanisme penyumbat dan penyegelan: tanpa botol, tanpa penyumbat dan penyegelan. Serat optik independen untuk mengontrol.

Penghenti tangan mekanis

Penghenti tangan mekanis Selongsong pelindung serat optik

Selongsong pelindung serat optikMekanisme tutup sekrup dan penjepit botol: dilengkapi perangkat geser otomatis, perangkat penjepit botol, menghindari botol mengikuti putaran. Tutup pelindung.

Tutup sekrup

Tutup sekrup Alat penjepit botol

Alat penjepit botol

Proses Operasi:

1. Persiapan bahan: Siapkan botol secukupnya, pasang, tutup, dan obat cair, pasang dan tutup harus penuh dengan rel hopper getaran dan terletak di lokasi penutup dalam dan luar

2. Botol pengumpan: meja putar pengumpan botol membuat botol (opsional)

3. Pengisian: Botol dengan osilasi merapikan pembuka botol untuk memposisikan cakram tebal, dengan memposisikan cakram lagi drive intermiten untuk mengisi, stoppering, penutup, tutup sekrup. Solusi dengan hisapan pompa peristaltik oleh pipa silikon, di stasiun pengisian lagi oleh jarum dapat digerakkan ke atas dan ke bawah secara otomatis mengisi cairan di dalam botol. Jarum setiap gerakan ke atas dan ke bawah, untuk menyelesaikan pengisian

4. Penyumbatan: Penyumbat disediakan oleh hopper getaran ke stasiun penyumbat, pergerakan botol dengan izin roda ke stasiun penyumbat, melalui deteksi serat optik untuk mengontrol sinyal kerja katup solenoid silinder yang tersumbat untuk mengontrol kerja silinder sehingga mencapai botol gasser tidak berfungsi, bukan penyumbat botol yang tersumbat pada pelat menggunakan desain prinsip gravitasi, hindari pegas atau pelat pegas yang dibuat sebelum ketidakstabilan terjadi setelah waktu yang lama, sehingga penyumbatnya sangat akurat

5. Capping: Tambahkan colokan yang bagus di dalam botol lagi dengan memposisikan cakram yang dikirim ke affix, tutup sekrup, affix prinsip yang sama dan buang air kecil pada prinsipnya, dilakukan oleh silinder, yang menutupi berbagai ukuran dengan tutup sekrup yang lengkap dan terus berputar di bawah dan secara keseluruhan naik turun, ketika botol berhenti tepat, penurunan putaran perangkap tutup sekrup kesopanan selesai. Badan tutup sekrup mengadopsi desain torsi konstan, sesuai dengan tutup botol dan ulir botol dengan torsi, untuk menyesuaikan kekencangan tutup sekrup setelah menempatkan di tempat dapat meluncur otomatis, mencapai tujuan penutup tidak terluka bukan botol

6. Botol keluar: Putar botol penutup yang baik lagi dengan botol bundar ke sabuk konveyor, tarik pengiriman akhir di luar mesin, dan masukkan proses pengemasan berikutnya

Catatan:

1. Mesin MENGGUNAKAN steker unik, dipasang pada steker dengan presisi.

2, tidak ada botol tidak bisa diisi, tidak ada botol tidak ada colokannya, tidak ada fungsi penutup colokan.

3, dengan saklar berhenti darurat, alarm otomatis saat mesin rusak.

4, mesin ini dengan penutup debu