Mesin Pengisian Overflow Otomatis Viskositas Rendah VK-OF

Cara Kerjanya:

Sisi suplai (biru tua) dari nosel dua bagian digunakan untuk memompa produk ke dalam wadah. Ketika wadah terisi hingga ketinggian pengisian target, kelebihan produk dan busa dipaksa keluar dari wadah (panah merah) melalui sisi pengembalian ke tangki sumber produk awal.

Aplikasi:

Jenis pengisi ini paling cocok untuk cairan dengan viskositas rendah hingga sedang. Cairan dengan partikel padat tidak melebihi 1/16″ juga dapat diisi. Perlu diketahui bahwa pengisi luapan adalah mesin pilihan untuk menangani produk yang sangat berbusa pada kecepatan tinggi.

Contoh:

Saus, sirup, gel ringan dan sampo, pembersih berbusa dan bahan kimia, air dan minuman berair non-karbonasi lainnya.

Keuntungan:

Performa tinggi, mudah dibersihkan, mudah dioperasikan, dan dapat diperluas dengan biaya rendah. Menawarkan fleksibilitas tertinggi dengan biaya terendah.,

Rincian Cepat

Mesin pengisian motor servo otomatis VK-OF dirancang dan diproduksi khusus oleh VKPAK, Sebagian besar digunakan untuk mengisi cairan kental, seperti produk kosmetik, produk kimia sehari-hari, dan juga untuk produk makanan, seperti mesin pengisi cuka, mesin pengisi pembersih tangan.

Bahan Kemasan: Kayu

Tipe: Mesin Pengisi

Kondisi: Baru

Tempat Asal: Shanghai, Tiongkok

Nama Merek: VKPAK

Daya: 2500W

Tegangan: 220V 50HZ

Aplikasi: Minuman, Kimia, Makanan, Medis

Berat: 400KG

Kelas Otomatis: Otomatis

Sertifikasi: ISO9001 CE GMP

Tipe Penggerak: Mekanik

Model: VK-OF

Nama: Mesin Pengisian Jus E-liquid Otomatis

Fungsi: Mesin pengisian cairan, stopper dan capping

Volume pengisian: 100ml-5000ml

Kontrol: PLC dan Layar Sentuh

Cocok: Cairan berbusa tinggi, viskositas rendah, cuka, kecap, anggur putih, pembersih tangan, dll.

Garansi: 12 Bulan

Bahan: Baja Tahan Karat 304/316

Kapasitas: 500-4000 Botol/jam

Jenis botol: plastik, botol kaca

Layanan Purnajual yang Disediakan: Teknisi tersedia untuk melayani mesin di luar negeri

Pabrik pengisi luapan otomatis viskositas rendah VK-OF adalah pengisi yang sangat fleksibel, terutama untuk cairan dari yang encer hingga berdensitas tinggi, seperti cuka, kecap, anggur putih, pembersih tangan, dan sebagainya. Produk ini banyak digunakan dalam industri kimia, makanan, dan farmasi.

Suku cadang diproses menggunakan mesin CNC dengan baja tahan karat impor berkualitas tinggi, sementara semua komponen utamanya diimpor dari Jepang, Jerman, Italia, dan Amerika. Sepenuhnya otomatis, dikontrol oleh PLC, dioperasikan melalui layar sentuh, mudah dioperasikan, dan hampir tidak memerlukan perawatan.

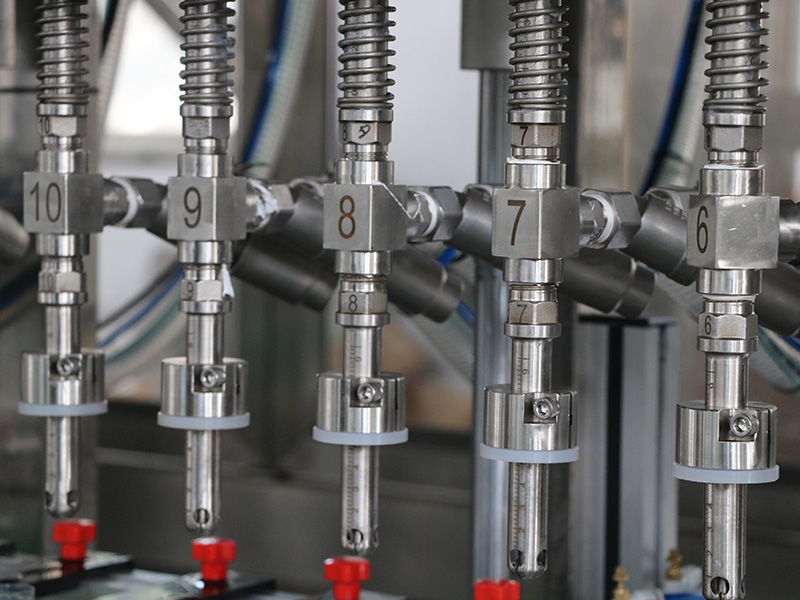

Pabrik pengisi luapan otomatis viskositas rendah diproduksi dengan rangka baja tahan karat 304 dan mampu mendukung 2 hingga 16 nosel pengisian, Kontrol PLC, layar sentuh.

| Nama | Mesin Pengisian Overflow Otomatis Viskositas Rendah VK-OF |

| Model | VK-OF |

| Nozel Pengisian | 2-16 nozel, atau disesuaikan |

| Kekuatan | 0,75 kW-2,5 kW |

| Kisaran botol yang diterapkan | 30-100ml, 100-1000ml, 900ml-5000ml |

| Akurasi Pengisian | ≤ ±0,5% |

| Kecepatan pengisian | 500-4200 botol/jam, 24b/menit per 4 nozel pengisian 1L |

| Dimensi | Ukuran 2200*1400*2300 mm |

| Berat | 400kg |

| Catu daya | 220V Fase tunggal 50HZ 380V Tiga fase 50HZ |

Fitur Utama

- Antarmuka bahasa Inggris manusia-mesin, layar kontak cerdas, desain manusia, pengoperasian mudah.

- Nozel pengisian luapan khusus, tingkat akurasi pengisian.

- Pengontrol logika program (PLC), mudah untuk mengubah ukuran atau memodifikasi parameter.

- Semua elemen pneumatik diimpor, stabil dan andal.

- Penginderaan foto-listrik dan kontrol penghubung pneumatik, perlindungan otomatis terhadap kekurangan botol.

- Desain posisi tertutup, pengaturan mudah, cocok untuk pengemasan botol segala ukuran.

- Seluruh mesin dirancang sesuai persyaratan GMP.

- Penerapan pengisian pompa, pengisi luapan untuk menyerap busa & menghilangkan busa yang meluap & menetes.

- Mengadopsi hopper cairan rendah, nyaman untuk membersihkan disinfeksi.

- Alat penjepit indeks leher, posisi mulut botol yang akurat sebelum nozel masuk ke dalam botol.

- Mudah untuk mengatur volume, mudah dioperasikan, mengganti botol yang berbeda dalam waktu singkat.

- Mesin dirancang dan diproduksi sesuai dengan peraturan GMP.

| Barang. | Asal |

| Nozel pengisian | VKPAK |

| Ban berjalan | VKPAK |

| Motor konveyor | Taiwan YN |

| PLC | Mitsubishi Jepang |

| Layar sentuh | Schneider |

| Kontaktor | Schneider Prancis |

| Pemecah | Schneider |

| Menyampaikan | Omron Jepang |

| SMPS | Taiwan MW |

| Pengatur Air/Minyak | Taiwan Airtac |

| Silinder | Taiwan Airtac |

| Katup solenoida pilot port | Taiwan Airtac |

| Sensor foto | Korea Autonics |

| Pompa Sentrifugal Sanitasi | asal cina |