Automatisk stempelviskøs væskefyllingsmaskin

Søknad:

Denne typen stempelfyller er best egnet for viskøse produkter som er pasta, semipasta eller tykke med store partikler. Disse stempelfyllerne er bygget for å oppfylle matkvalitetsstandarder og kan også håndtere ulike kjemiske applikasjoner.

Eksempler:

Tunge sauser, salsaer, salatdressinger, kosmetiske kremer, tunge sjampoer, geler og balsam, pasta- og voksrensemidler, lim, tunge oljer og smøremidler.

Fordeler:

Denne rimeligere konvensjonelle teknologien er lett å forstå for de fleste brukere. Raske fyllingshastigheter er oppnåelig med ganske tykke produkter. Advarsel: Denne teknologien er nesten foreldet med fremveksten av servo-positive fortrengningsfyllere.

Beskrivelse

Denne fyllemaskinen er en stempelfyllemaskin som er egnet for fylling av væsker med varierende viskositet. Maskinen er laget med en inline-struktur, og mengden fyllehode kan tilpasses i henhold til ulik produksjonskapasitet, for eksempel 6/8/10/12/16/20 hoder.

Fyllingssystemet drives av en servomotor som sikrer høy fyllingsnøyaktighet, og det er også enkelt å stille inn fyllevolumet direkte på berøringsskjermen.

Det er mye brukt i kosmetikk-, næringsmiddel-, spesialkjemisk-, farmasøytisk og personlig pleieindustrien.

VK-PF automatisk servomotordrevet stempelfyllemaskin er spesialdesignet og produsert av VKPAK. Den brukes hovedsakelig til fylling av viskøse væsker, for eksempel kosmetikkprodukter, daglige kjemiske produkter, og også for matvarer, som honningfyllemaskin og sausfyllemaskin.

Emballasjetype: Flasker

Emballasjemateriale: Tre

Type: Fyllingsmaskin

Tilstand: Ny

Ettersalgsservice levert: Online support, videoteknisk support, gratis reservedeler, feltinstallasjon, igangkjøring og opplæring

Opprinnelsessted: Shanghai, Kina

Merkenavn: VKPAK Billig stempelautomatisk fyllemaskin for saus

Spenning: 220V/380V

Bruksområde: Mat

Vekt: 1200 kg

Automatisk karakter: Automatisk

Drevet type: Elektrisk

Dimensjon (L * B * H): 2500 * 1400 * 2500 mm

Navn: Billig stempelautomatisk fyllemaskin for saus

Kontaktmateriale: 316SS

Kontroll: Servomotorkontroll fyllevolum

Behandlingstyper: Fylling av væskefylling i flaske

Fyllingsvolum: 1000 ml–5000 ml og 100 ml–1000 ml

Maskinnavn: automatisk fyllemaskin for saus

Materiale: Rustfritt stål

Kapasitet: 800–4200 BPH

fyllingsnøyaktighet: 0,2%

Ulike typer VKPAK automatisk stempelfyllemaskin

Det finnes mange modeller og typer sausfyllemaskiner basert på forskjellig kapasitet, antallet fylldyser er fra ett hode til 16 hoder, og fyllvolumet er fra 100 g til 1000 g.

Hovedstruktur av automatisk stempelfyller

- 20L til 200L toppbeholder som tilleggsutstyr, dobbel jakkebeholder med varme- og blandesystem som tilleggsutstyr,

- Hoveddel av maskinen laget av 304SS

- Fylledyser, fylledyser er spesialdesignet for anti-drop sausfylling

- Fylledyser som beveger seg opp og ned med luftsylinder, og servomotor som beveger seg opp og ned for valgfritt alternativ

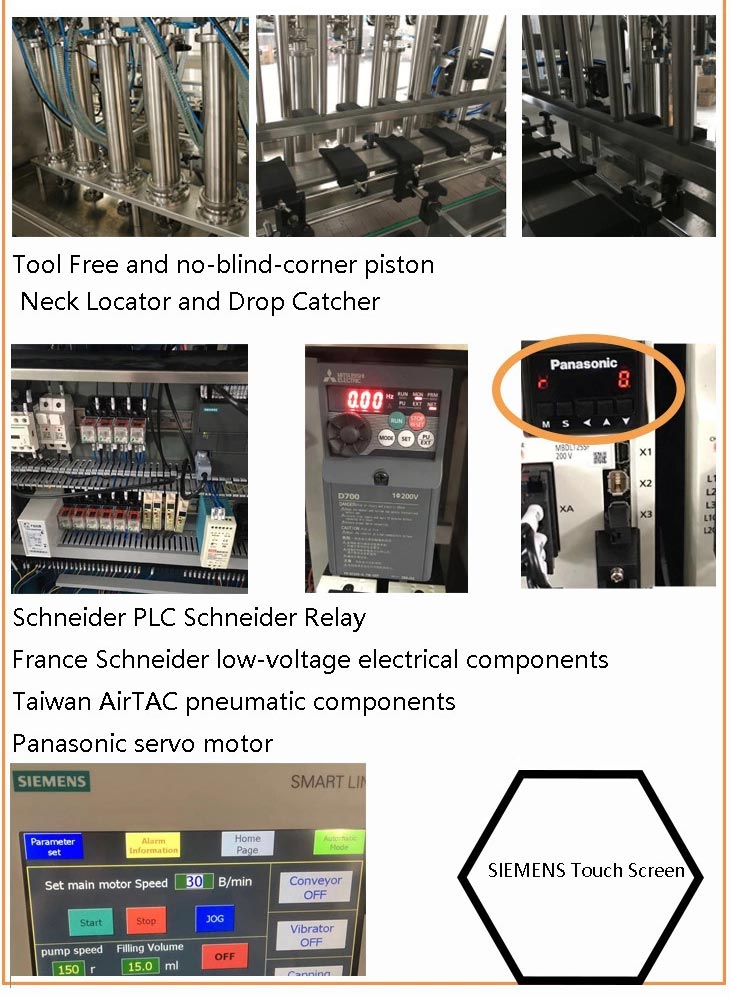

- PLS-kontrollsystem og HMI-drift

- Spesiallaget hest og ventil for honning, med CIP-system som kobler hest til.

Konkurransefordel ved automatisk stempelfyller

Det er mange fordeler med den automatiske stempelfyllemaskinen

- PLS-kontroll, betjening på berøringsskjerm.

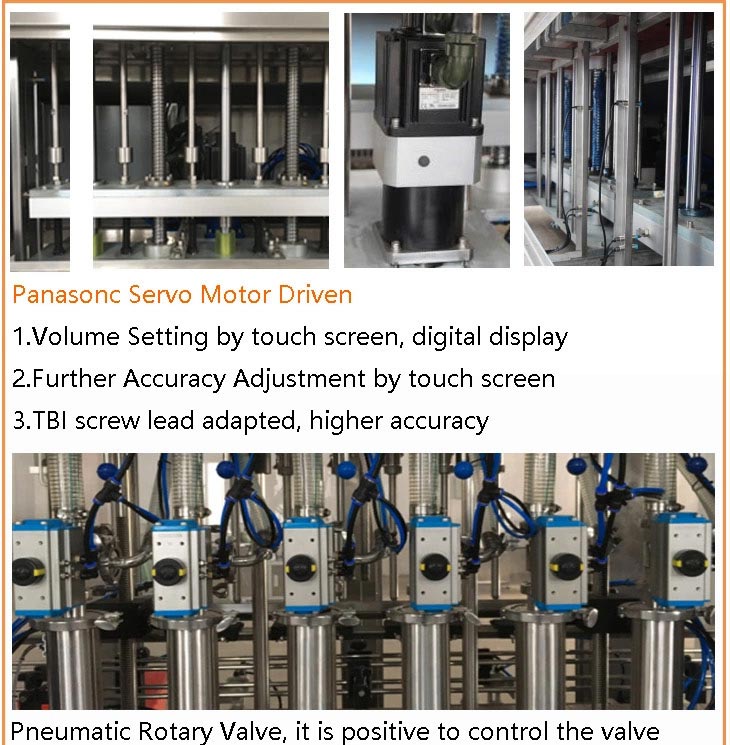

- Panasonic servomotordrevet, automatisk justering av fyllingsstørrelsen på HMI, f.eks. Brukere som ønsker å fylle 500 g saus, skriver bare inn tallet 500, så vil maskinen justere seg automatisk.

- Den er volumetrisk med stempel, høy fyllingsnøyaktighet.

- Med dobbeltmantlede varme- og blandetanker på toppen.

- Den automatiske sausfyllingsmaskinen kan også ha funksjonen via CIP-system som kobler brukerens CIP-system.

- Hesten til sausfylleren er spesiallaget i henhold til sausens natur, ingen døde hjørner, matkvalitet.

- De myke rørene eller rørene på sausfylleren er tilpasset det verdenskjente merket Toyox fra Japan.

- Spesiallaget rotasjonsventil for overføring av viskøs saus.

Teknisk parameter

| Fylledyser | 1-16 Dyser |

| Produksjonskapasitet | 800–5000 flasker per time |

| Fyllingsvolum | 100–500 ml, 100 ml til 1000 ml |

| Makt | 2000 W, 220 V AC |

| Nøyaktighet | ±0,1% |

| Drevet | Panasonic servomotor |

| Grensesnitt | Schneider berøringsskjerm |

Produkter som skal fylles:

1) varmfylling (35 ~ 40 ℃), kaldfylling normal temperatur

2) Spesifikk vekt: 1,1 ~ 1,4 gr/cm3

3) Smøre sjokoladepasta • Honning • Smøre ostepasta, melasse.

Flasketype:

1) PET-flaske • Kvadrant Tverrsnitt • Volum 250 ml • Hals 32 mm.

2) Glasskrukker og PE- og PET-krukker • Sylindrisk tverrsnitt • Volum 200 ~ 350 ml • Hals 45 mm.

Fyllingstoleranser: +/- maks 0,5%

Detaljbilder

Hovedfunksjoner:

- Enkel å justere fyllvolumet, automatisk justering via berøringsskjerm, høy nøyaktighet og stabil hastighet.

- Lineært fyllesystem er enkelt å justere for mange forskjellige typer flasker

- Lett å vedlikeholde, ingen spesialverktøy kreves.

- Ingen flaske, ingen fylling, automatisk PLS-kontroll

- blokkerte fylldyser er anti-dråper, silke og automatisk kuttet viskøs væske

- Nøyaktig fyllevolum, innenfor ±0,5-1% og en total flasketeller.

- Spesielle tetninger eller slanger tilpasses hvis væsken er etsende.

- Dykkerdyser for fylling av skummende produkter nedenfra og opp ved behov

- Flaskemunnen kan lokaliseres

VKPAK automatisk stempelfyller er en ekstremt fleksibel fyller som er i stand til å fylle alle viskøse væsker nøyaktig og raskt. Produktlevering fra bulktanken til stemplene kan konfigureres med en buffertank som bruker en nivåfølende flottør, en manifold med direkte trekk eller resirkuleringsmetoder. VKPAK automatisk stempelfyller er produsert med en ramme i rustfritt stål 304 og kan støtte 1 til 16 fyllehoder. PLS-kontroller, berøringsskjerm HMI, kontaktdeler i næringsmiddelkvalitet, konstruksjon i rustfritt stål og anodisert aluminium og mange flere funksjoner er standard. VKPAK automatiske stempelfyllere er designet for å øke effektiviteten til enhver produksjonslinje som brukes i kosmetikk-, næringsmiddel-, spesialkjemisk-, farmasøytisk og personlig pleieindustrien. Ytterligere alternativer er tilgjengelige for sanitære, farlige, brannfarlige og korrosive miljøer.

VKPAK er designet for å gi maksimal effektivitet og enkelt vedlikehold, og er avhengig av intuitiv konstruksjon, rimelighet, allsidighet og effektivitet når de leverer stempelfyllemaskiner av høyeste kvalitet for flytende emballasjesystemer.

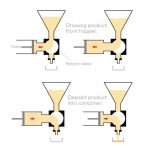

Stempelfyllemaskiner fra VKPAK bruker et volumetrisk fylleprinsipp for et bredt spekter av forskjellige produkter. På både halvautomatiske og automatiske stempelfyllere trekkes stempelet tilbake for å la et bestemt volum av produktet fra forsyningssystemet komme inn i sylinderen. Produktet skyves deretter ut av dysen og inn i ventebeholderne når stempelet returnerer til sylinderen.

Selv om stempelfyllere kan håndtere et bredt spekter av viskositeter, er de ofte det ideelle valget for produkter med høyest viskositet, så vel som produkter med store partikler.

Med et bredt utvalg av produkter av høy kvalitet kan kundene regne med maksimal kompatibilitet, holdbarhet og fleksibilitet. Disse maskinene er designet for å gjøre produksjonslinjen din effektiv.

Kontakt oss for å finne din løsning i dag!