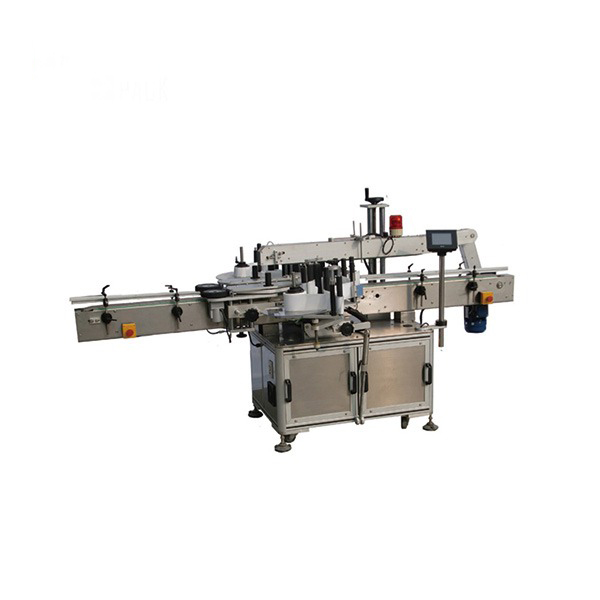

Máquina automática de rotulagem de garrafas planas

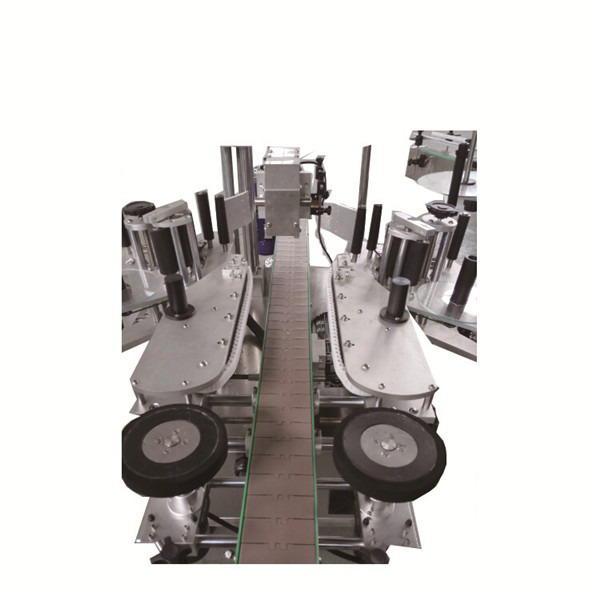

Esta máquina automática de rotulagem de garrafas planas separa as garrafas. Um único motor controla o dispositivo de prensagem e a esteira transportadora, permitindo que as garrafas se movam linearmente sobre a esteira. Servomotores, CLP e tela sensível ao toque garantem a alta qualidade da rotulagem.

Esta máquina automática de rotulagem de garrafas planas separa as garrafas. Um único motor controla o dispositivo de prensagem e a esteira transportadora, permitindo que as garrafas se movam linearmente sobre a esteira. Servomotores, CLP e tela sensível ao toque garantem a alta qualidade da rotulagem.

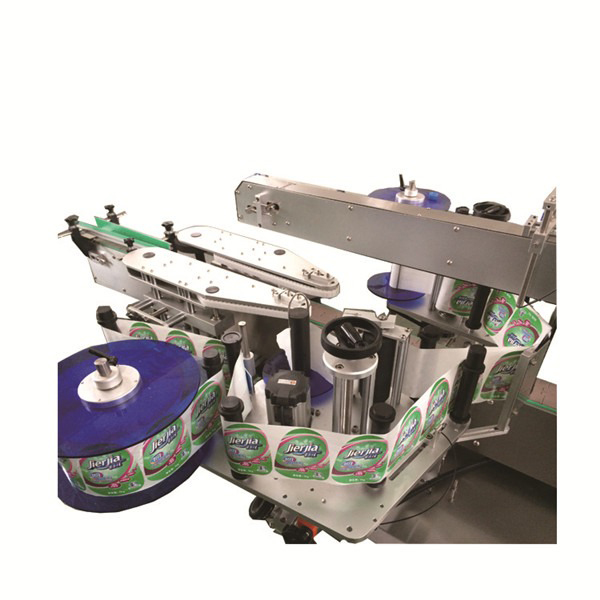

A máquina automática de rotulagem de garrafas planas foi projetada para rotular garrafas planas e quadradas em ambos os lados. Ela foi desenvolvida para atender às necessidades de alguns clientes que precisam rotular garrafas redondas e com rótulos em ambos os lados. É ideal para produtos como medicamentos, produtos químicos de uso diário, alimentos, produtos de higiene, eletrônicos, entre outros. Esta máquina é controlada por servomotor, CLP e tela sensível ao toque, sendo uma rotuladora multietiqueta/adesiva.

Descrição

A máquina de etiquetagem de adesivos planos é utilizada para etiquetar um lado de recipientes planos ou aplicar etiquetas que envolvem total ou parcialmente recipientes de diversas dimensões. Esta máquina robusta possui um acabamento liso em aço inoxidável, incluindo a estrutura principal. É um equipamento extremamente fácil de usar, com capacidade de etiquetar de 30 a 350 unidades por minuto, dependendo do tamanho do produto e da etiqueta. A velocidade também depende do movimento estável do recipiente na esteira da máquina em velocidades mais altas. Este modelo sofisticado e simples possui o mais recente dispositivo de espaçamento da correia, o que resulta em um sistema sem necessidade de troca de peças, mesmo que o tamanho dos recipientes e das etiquetas seja alterado. Além disso, a máquina inclui um sistema de controle de ponto único avançado e distinto para variação de velocidade online. Ademais, este equipamento versátil e preciso é reconhecido por sua alta precisão na colocação de etiquetas. Ele também incorpora um sistema integrado de inversor de frequência CA.

Tipo de embalagem: Garrafas

Material da embalagem: Metal

Tipo: Rotuladora, Rotuladora

Condição: Novo

Serviço pós-venda oferecido: Suporte online, suporte técnico por vídeo, peças de reposição gratuitas, instalação, comissionamento e treinamento em campo.

Local de origem: Xangai, China

Marca: VKPAK

Voltagem: 220V 50/60Hz

Aplicações: Vestuário, Bebidas, Produtos Químicos, Alimentos, Medicina

Peso: 200 kg

Grau automático: Automático

Tipo de acionamento: Mecânico

Dimensões (C*L*A): 1800 mm * 1000 mm * 1300 mm

Função: etiqueta adesiva na garrafa

Velocidade de rotulagem: 20-100 garrafas/min

Motor: servomotor

Nome da máquina: máquina de aplicação de etiquetas

Material: Aço inoxidável

Garantia: 1 ano

Precisão da etiquetagem: 1 mm

Serviço: Suporte técnico 24 horas por dia, 7 dias por semana

Embalagem: Caixa de madeira para longas distâncias

Parâmetro técnico

| Nome | Máquina automática de rotulagem de garrafas planas |

| Velocidade de etiquetagem | 60-350 unidades/min (dependendo do comprimento do rótulo e da espessura da garrafa) |

| Altura do objeto | 30-350 mm |

| Espessura do objeto | 20-120 mm |

| Altura da etiqueta | 15-140mm |

| Comprimento do rótulo | 25-300 mm |

| Diâmetro interno do rolo de etiqueta | 76 mm |

| Diâmetro externo do rolo de etiqueta | 420 mm |

| Precisão da rotulagem | ±1mm |

| Fonte de energia | 220V 50/60HZ 3,5KW Monofásico |

| Consumo de gás da impressora | 5 kg/cm² |

| Dimensões da máquina de rotulagem | 2800 (C) × 1650 (L) × 1500 (A) mm |

| Peso da máquina de rotulagem | 450 kg |

Principais características:

- PLC e tela sensível ao toque, servomotor

- Equipado com dispositivo de aviso para etiquetas insuficientes ou danificadas.

- Sem garrafa, sem rótulo

- Sem rótulos, sem rotulagem e com aviso automático.

- Sem Ribbon, aviso automático

- Controle de servomotor, etiquetagem estável.

- O sensor de etiquetas e as peças elétricas são fabricados no Japão.

- Adequado para garrafas redondas, planas ou quadradas.

A máquina pode utilizar etiquetas com comprimento mínimo de 12 mm e altura que varia de 8 mm a 70/90/120/150 mm. Normalmente, o diâmetro do rolo é de 300 mm e o diâmetro do núcleo é de 75 mm. O espaçamento entre duas etiquetas é de aproximadamente 3 mm. Além disso, possui um sistema automático integrado de detecção do comprimento da etiqueta, que elimina a necessidade de inserir e armazenar manualmente os dados do comprimento da etiqueta na memória e recuperá-los quando o tamanho da etiqueta é alterado e a máquina é reiniciada. Este sistema moderno reduz custos, economiza tempo valioso, evita paradas da máquina e permite alcançar maior produtividade. Este modelo está disponível com uma cabine de segurança opcional em vidro ou acrílico resistente. Na verdade, atende a todos os requisitos básicos de uma máquina típica exigida no mercado atual.