Automatisk roterende peristaltisk pumpeflaskepåfyldningsmaskine

Sådan fungerer det:

Den peristaltiske pumpe har kun intermitterende kontakt på ydersiden af den kirurgiske (produkt-) slange, så produktet kun berører indersiden af slangen. Fylderens mastercomputer sporer uafhængigt omdrejningerne af det peristaltiske pumpehoved, så den præcist ved, hvor meget produkt der er blevet leveret. Når den ønskede påfyldningsvolumen er nået, stopper pumpen, og den resterende produktvæske drypper ikke ud på grund af pipettefunktionen. Computeren gemmer alle påfyldningsparametre i hukommelsen for hurtige skift.

Anvendelse:

Specielt designet til påfyldninger af høj værdi og små volumener med meget høj nøjagtighed. Velegnet til vandige og andre letviskose produkter.

Eksempler:

Farmaceutiske præparater, duftstoffer, æteriske olier, reagenser, blæk, farvestoffer og specialkemikalier.

Fordele:

Væskebanen er engangs; nem rengøring og eliminering af krydskontamineringsproblemer. Nøjagtigheder på 0,5% kan opnås for påfyldningsvolumener på mindre end 1 ml.

Beskrivelse

High precision peristaltic pump filling, measuring accurate, adjustable, clean, convenient maintenance, easy operation, no bottle no filling, no bottle no plug, not plug cover function. Work surface with 304 high-quality stainless-steel materials protection, contact with the liquid part is 316L quality stainless steel, the machine meets GMP requirements.

This machine is applicable to the pharmaceutical industry in the bottle of liquid filling and sealing packing process, etc. The aircraft structure is reasonable, automatically unscramble bottle, filling and plug, plug, cover, cover, screw cap, high precision CAM indexer for uniform chart positioning, no clearance, positioning accuracy;

Emballagemateriale: Træ

Type: Påfyldningsmaskine

Stand: Ny

Oprindelsessted: Shanghai, Kina

Brand Name: VKPAK Peristaltic pump spray bottle liquid filling machine

Model Number: VK-MFC Peristaltic pump spray bottle liquid filling machine

Effekt: 2000W

Spænding: 220V 50Hz

Anvendelse: Drikkevarer, Kemikalier, Fødevarer, Medicin

Vægt: 400 kg

Automatisk karakter: Automatisk

Certificering: ISO9001 CE GMP

Dimensioner (L*B*H): 3000 mm * 1300 mm * 1700 mm

Name: Peristaltic pump spray bottle liquid filling machine

Model: VK-MFC Peristaltic pump spray bottle liquid filling machine

Funktion: Væskepåfyldnings-, prop- og afdækningsmaskine

Påfyldningsvolumen: 3 ml-30 ml og 30 ml-100 ml og 100 ml-500 ml

Styring: PLC og berøringsskærm

egnet til: Hætteglas, parfume, oral væske, E-væske, øjendråber

Materiale: Rustfrit stål 304/316

Garanti: 12 måneder

Capacity: 20-80bottles/minute

Processing Types: Normal Pressure Filling

Eftersalgsservice leveret: Ingeniører til rådighed for service af maskiner i udlandet

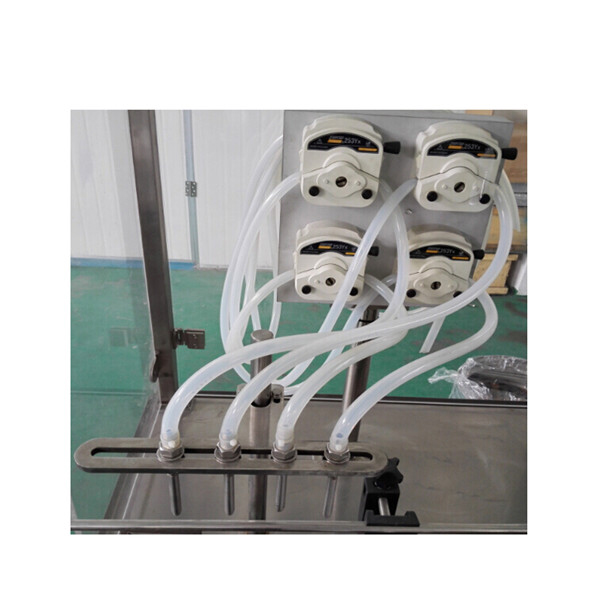

The machine is mainly composed of dust shield, conveyor belt, electrical box, rack, stoppering hopper, capping hopper, turntable and peristaltic pump, etc.

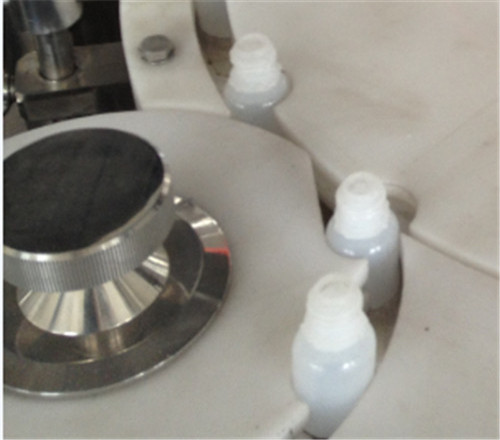

Prepare adequate bottles,inner plug,outer caps and fluids;the track of oscillation hopper should be filled with inner plugs and outer caps,and located at outside capping station. Bottles are supplied by bottle machine or manually,transferred by conveyor belt; bottles transferred by conveyor belt should be transferred by in-bottle driver plate to positioning round plate. Two bottles are pulled into to each revolution of in-bottle driver plate;and then, the bottles are transferred by positioning round plate intermittently to filling,stoppering,hanging and capping stations.

Teknisk parameter

| Produktionskapacitet | 20-80bottles/minute |

| Applied bottles | 2-30ml bottles |

| Påfyldningsdyse | 2 dyser |

| Fyldningsnøjagtighed | ≤ ±1% |

| Tryk på dyserne til afdækning | 1 dyser |

| Loftsats | 99% eller mere (afhængigt af stikkets egenskaber, passende justering) |

| Hastighedskontrol | frekvensstyring |

| Flaskestørrelse | Mere end 10 mm |

| Strømforsyningen | 380V 50Hz, or customized |

| Magt | 2kw |

| Lufttilførsel | 0,3~0,4 kfg/cm² |

| Gasforbrug | 10~15 m³/t |

| Samlede dimensioner | 2600*1300*1600mm |

Main configuration:

Mesa, around the side plates are of high quality 304 stainless steel or other FDA approval of material production, and material contract parts for 316L quality stainless steel.

| Filling nozzle material | SUS 316L stainless steel |

| Filling type | Peristaltic pump |

| CAM indexing | Shandong zhucheng |

| The inverter | Japan's mitsubishi |

| PLC | Siemens |

| Berøringsskærm | Siemens |

| Main motor | ABB |

| low-voltage apparatus | Schneider |

| Servo motor | Taiwan TECO |

Detaljebilleder

Stoppering and sealing mechanism: no bottle ,no stoppering and sealing.Independent optical fiber to control.

Mechanical hand stoppering

Mechanical hand stoppering Optical fiber protective sleeve

Optical fiber protective sleeveScrewing cap and clamping bottle mechanism: possess automatic sliding device,clamping bottle device,avoid bottle follow to rotation.Protective cap.

Screw cap

Screw cap Clamping bottle device

Clamping bottle device

Operation Precess:

1. Material preparation: Ready enough bottles, plug in, cover, and liquid medicine, plug and cover should be full of vibration hopper rail and is located in the inside and outside cover location

2. Feeder bottles: bottle feeder turntable make the bottles (optional)

3. Filling: Bottle by oscillation tidy up the bottle opener for positioning disk thick, by positioning disk again intermittent drive to filling, stoppering, cover, screw cap.Solution by peristaltic pump suction by silicone pipe, at the filling station again by the needle can be moved up and down automatically filling liquid in the bottle.The needle every move up and down, to complete a filling

4. Plugging: Plug is provided by vibration hopper to stoppering station, bottle movement by wheel clearance to stoppering station, through the optical fiber detection to control stoppered cylinder solenoid valve work signal to control the cylinder work so as to achieve a bottle gasser no function, not stoppered bottle plug on plate using gravity principle design, avoid the spring or spring plate made before instability happens after long time, so the plug is very accurate

5. Capping: Add good plug inside the bottle again by positioning disc sent to the affix, screw cap, affix a similar principle and urinating in principle, is done by the cylinder, covering various size by complete, constantly rotating screw LIDS below and overall do up and down, when the bottle stops right, decline of spin trapping modesty lid screw cover finish.Screw cap body adopts the design of constant torque, according to the bottle cap and bottle thread with torsion, to adjust the firmness of the screw cap after putting in place can automatic sliding, achieve the goal of not wounded cover not bottles

6. Bottles out: Spin good cover bottle again by the bottle round to the conveyor beltpull pull final delivery outside the machine, and enter the next packaging process

Note:

1, the machine USES unique plug, fixed on plug on precision.

2, no bottle no filling, no bottle no on plug, not plug cover function.

3, with urgent stop switch, automatic alarm when machine is out of order.

4, this machine with dust cover