VK-OF automatisk overløbsfyldemaskine med lav viskositet

Sådan fungerer det:

Tilførselssiden (mørkeblå) af en todelt dyse bruges til at pumpe produktet ned i beholderen. Når beholderen er fyldt op til den ønskede fyldehøjde, presses det overskydende produkt og skum ud af beholderen (røde pile) via retursiden til den oprindelige produktkildetank.

Anvendelse:

Denne type fyldstof er bedst egnet til væsker med lav til medium viskositet. Væsker med faste partikler, der ikke overstiger 1/16″, kan også fyldes. Bemærk, at overløbsfyldere er den foretrukne maskine til håndtering af meget skummende produkter ved højere hastigheder.

Eksempler:

Saucer, sirupper, lette geler og shampooer, skummende rensemidler og kemikalier, vand og andre ikke-kulsyreholdige vandige drikkevarer.

Fordele:

Høj ydeevne, nem at rengøre, nem at betjene, kan udvides til en lav pris. Giver den største fleksibilitet til den laveste pris,

Hurtige detaljer

VK-OF automatiske servomotordrevne påfyldningsmaskine er specielt designet og fremstillet af VKPAK. Den anvendes primært til påfyldning af viskøse væsker, såsom kosmetiske produkter, daglige kemiske produkter og også til fødevarer, såsom... eddikepåfyldningsmaskine, håndspritpåfyldningsmaskine.

Emballagemateriale: Træ

Type: Påfyldningsmaskine

Stand: Ny

Oprindelsessted: Shanghai, Kina

Mærkenavn: VKPAK

Effekt: 2500W

Spænding: 220V 50Hz

Anvendelse: Drikkevarer, Kemikalier, Fødevarer, Medicin

Vægt: 400 kg

Automatisk karakter: Automatisk

Certificering: ISO9001 CE GMP

Drevet type: Mekanisk

Model: VK-OF

Navn: Automatisk E-væske Juice Fyldningsmaskine

Funktion: Væskepåfyldnings-, prop- og afdækningsmaskine

Påfyldningsvolumen: 100 ml-5000 ml

Styring: PLC og berøringsskærm

Velegnet til: Højskummende væske med lav viskositet, eddike, sojasauce, hvidvin, håndsprit osv.

Garanti: 12 måneder

Materiale: Rustfrit stål 304/316

Kapacitet: 500-4000 flasker/t

Flasketype: plastik, glasflaske

Eftersalgsservice leveret: Ingeniører til rådighed for service af maskiner i udlandet

VK-OF lavviskositets automatisk overløbsfylder fra fabrikken er et ekstremt fleksibelt fyldstof, specielt til væsker fra tyndt viskøse til højdensitetsvæsker, såsom eddike, sojasauce, hvidvin, håndsprit osv. Det bruges mest i kemikalie-, fødevare- og medicinalindustrien.

Reservedelene fremstilles med CNC-maskiner med importeret rustfrit stål af høj kvalitet, og alle hovedkomponenter importeres fra Japan, Tyskland, Italien og Amerika. Fuldautomatisk, styret af PLC, betjenes via berøringsskærm, nem betjening og næsten ingen vedligeholdelse nødvendig.

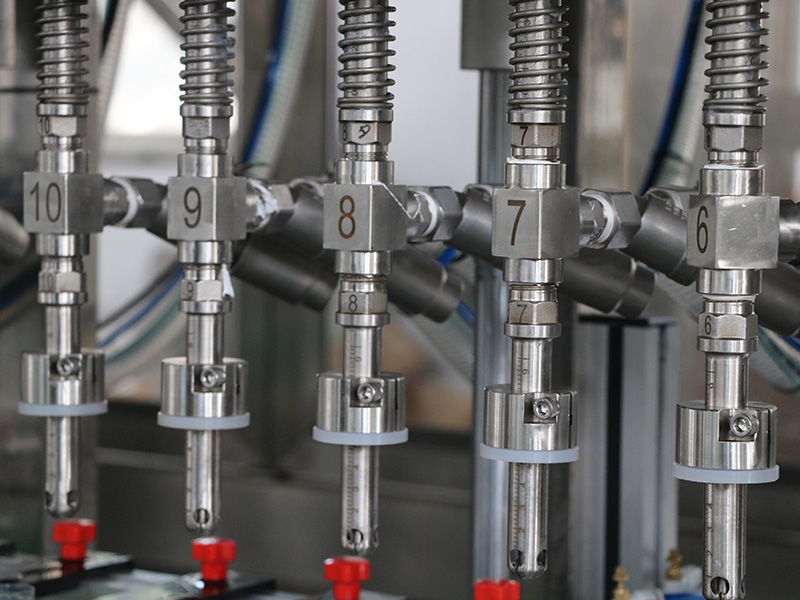

Den automatiske overløbspåfyldningsfabrik med lav viskositet er fremstillet med en ramme i rustfrit stål i 304 og kan understøtte 2 til 16 påfyldningsdyser, PLC-styringer og berøringsskærm.

| Navn | VK-OF automatisk overløbsfyldemaskine med lav viskositet |

| Model | VK-OF |

| Påfyldningsdyser | 2-16 dyser eller tilpasset |

| Magt | 0,75 kW-2,5 kW |

| Anvendt flaskesortiment | 30-100 ml, 100-1000 ml, 900 ml-5000 ml |

| Fyldningsnøjagtighed | ≤ ±0,5% |

| Påfyldningshastighed | 500-4200 flasker/time, 24 b/min pr. 4 påfyldningsdyser 1L |

| Dimension | 2200*1400*2300 mm |

| Vægt | 400 kg |

| Strømforsyning | 220V Enfaset 50HZ 380V Trefaset 50HZ |

Hovedfunktioner

- Menneske-maskine engelsk interface, intelligent kontaktskærm, menneskeligt design, nem betjening.

- Specielle overløbspåfyldningsdyser, nøjagtighedsniveau påfyldning.

- Programlogikcontroller (PLC), nem til at ændre størrelse eller modificere parametre.

- Pneumatiske elementer er alle importerede, stabilitet og pålidelighed.

- Fotoelektrisk registrering og pneumatisk koblingskontrol, automatisk beskyttelse ved flaskemangel.

- Tæt positioneringsdesign, nem styring, egnet til pakning af flasker i alle størrelser.

- Hele maskinen er designet i henhold til GMP-kravene.

- Implementering af pumpepåfyldning og overløbsfyldere for at absorbere skum og eliminere skumoverskud og dryp.

- Brug en tragt med lavt væskeindhold, der er praktisk at rengøre og desinfektion.

- Halsindeksklemmeanordning, præcis positionering af flaskemundingen før dyserne går ind i flaskerne.

- Praktisk at justere lydstyrken, nem at betjene, skift forskellige flasker på kort tid.

- Maskindesignet og fremstillet i overensstemmelse med GMP-reglerne.

| Punkt. | Oprindelse |

| Påfyldningsdyser | VKPAK |

| Transportbånd | VKPAK |

| Transportbåndsmotor | Taiwan YN |

| PLC | Japan Mitsubishi |

| Berøringsskærm | Schneider |

| Kontaktor | Fransk Schneider |

| Breaker | Schneider |

| Relæ | Japan Omron |

| SMPS | Taiwan MW |

| Vand-/olieregulator | Taiwan Airtac |

| Cylinder | Taiwan Airtac |

| Portpilot-magnetventil | Taiwan Airtac |

| Fotosensor | Korea Autonics |

| Sanitær centrifugalpumpe | Kinas oprindelse |