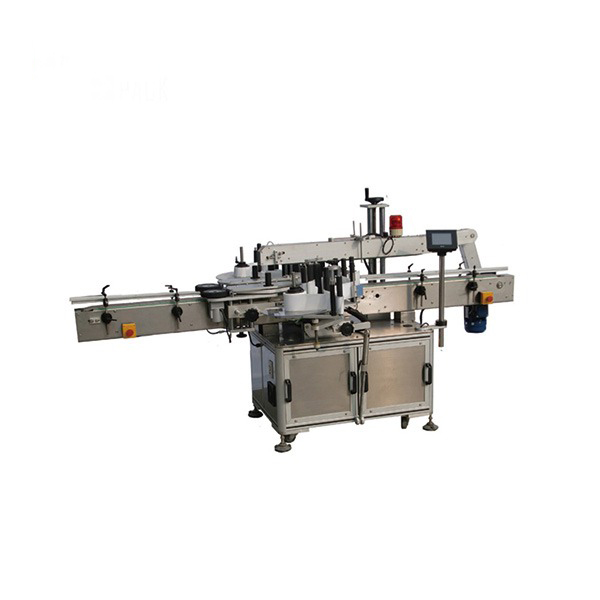

Automatische Flachflaschen-Etikettiermaschine

Diese automatische Flachflaschen-Etikettiermaschine trennt die Flaschen. Ein Motorantrieb steuert die Flaschenpresse und das Förderband, auf dem die Flaschen linear transportiert werden. Servomotor, SPS und Touchscreen sorgen für eine optimale Etikettierung.

Diese automatische Flachflaschen-Etikettiermaschine trennt die Flaschen. Ein Motorantrieb steuert die Flaschenpresse und das Förderband, auf dem die Flaschen linear transportiert werden. Servomotor, SPS und Touchscreen sorgen für eine optimale Etikettierung.

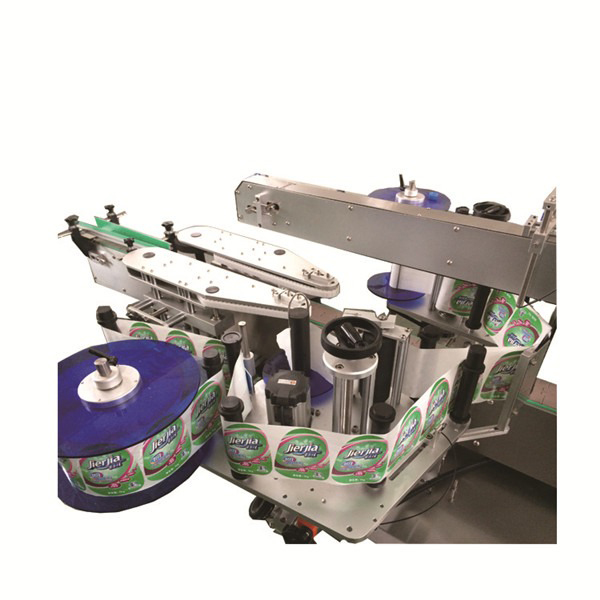

Die automatische Flachflaschen-Etikettiermaschine ist für die beidseitige Etikettierung von flachen und quadratischen Flaschen konzipiert. Sie erfüllt auch Kundenanforderungen hinsichtlich der beidseitigen Etikettierung von runden Flaschen. Anwendungsbereiche sind unter anderem die Pharmazie, Haushaltschemikalien, Lebensmittel, Elektronikartikel und vieles mehr. Die Maschine wird von einem Servomotor, einer SPS und einem Touchscreen gesteuert und ist für die Verwendung mit verschiedenen Etiketten/Klebstoffen geeignet.

Beschreibung

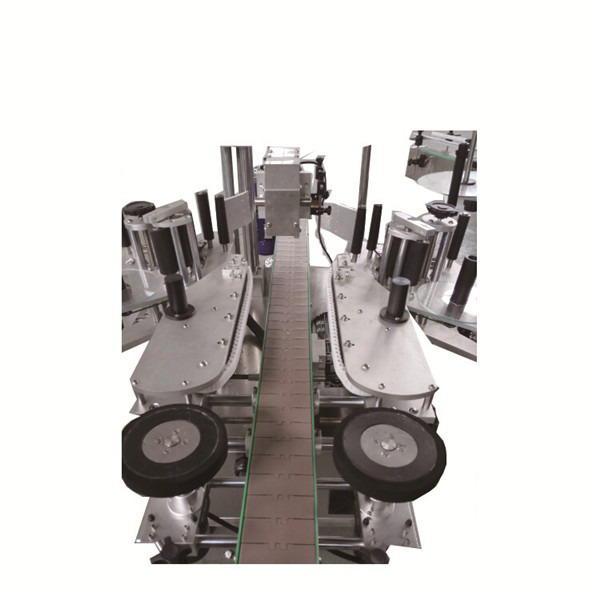

Die Flachetikettiermaschine dient zum Etikettieren einer Seite flacher Behälter oder zum Anbringen von Rundum- und Teilumhüllungsetiketten auf Behältern unterschiedlicher Größe. Die robuste Maschine verfügt über eine glatte Edelstahloberfläche, die auch das Hauptgehäuse umfasst. Sie ist äußerst benutzerfreundlich und etikettiert je nach Produkt- und Etikettengröße 30 bis 350 Einheiten pro Minute. Die Geschwindigkeit hängt auch von der stabilen Bewegung des Behälters auf dem Förderband ab. Dieses fortschrittliche und zugleich einfache Modell ist mit einer modernen Bandabstandsregelung ausgestattet, die einen Teilewechsel überflüssig macht, selbst bei wechselnden Behälter- und Etikettengrößen. Darüber hinaus verfügt die Maschine über ein fortschrittliches und präzises Einpunkt-Steuerungssystem zur stufenlosen Geschwindigkeitsanpassung. Die vielseitige und präzise Maschine zeichnet sich außerdem durch ihre hohe Etikettenplatzierungsgenauigkeit aus und ist mit einem integrierten Frequenzumrichter ausgestattet.

Verpackungsart: Flaschen

Verpackungsmaterial: Metall

Typ: Etikettiermaschine

Zustand: Neu

Kundendienst: Online-Support, technischer Video-Support, kostenlose Ersatzteile, Installation, Inbetriebnahme und Schulung vor Ort.

Herkunftsort: Shanghai, China

Markenname: VKPAK

Spannung: 220 V, 50/60 Hz

Anwendungsbereiche: Bekleidung, Getränke, Chemie, Lebensmittel, Medizin

Gewicht: 200 kg

Automatische Ausführung: Automatik

Antriebsart: Mechanisch

Abmessungen (L*B*H): 1800 mm*1000 mm*1300 mm

Funktion: Aufkleberetikett für die Flasche

Etikettiergeschwindigkeit: 20–100 Flaschen/min

Motor: Servomotor

Maschinenname: Etikettiermaschine

Material: Edelstahl

Garantie: 1 Jahr

Etikettierungsgenauigkeit: 1 mm

Service: Technischer Support rund um die Uhr

Verpackung: Langstrecken-Holzkiste

Technischer Parameter

| Name | Automatische Flachflaschen-Etikettiermaschine |

| Etikettiergeschwindigkeit | 60-350 Stück/min (abhängig von der Etikettenlänge und Flaschendicke) |

| Höhe des Objekts | 30-350 mm |

| Dicke des Objekts | 20-120 mm |

| Höhe des Etiketts | 15-140 mm |

| Länge des Etiketts | 25-300 mm |

| Innendurchmesser der Etikettenwalze | 76 mm |

| Außendurchmesser der Etikettierwalze | 420 mm |

| Genauigkeit der Etikettierung | ±1 mm |

| Stromversorgung | 220 V, 50/60 Hz, 3,5 kW, einphasig |

| Gasverbrauch des Druckers | 5 kg/cm² |

| Größe der Etikettiermaschine | 2800 (L) × 1650 (B) × 1500 (H) mm |

| Gewicht der Etikettiermaschine | 450 kg |

Hauptmerkmale:

- SPS und Touchscreen, Servomotor

- Ausgestattet mit einer Warnvorrichtung für unzureichende oder beschädigte Etiketten

- Keine Flasche, kein Etikett

- Keine Etiketten, keine Kennzeichnung und automatische Warnung

- Kein Farbband, automatische Warnung

- Servomotorsteuerung, stabile Etikettierung.

- Etikettensensor und elektrische Bauteile werden in Japan hergestellt.

- Geeignet für runde/flache/eckige Flaschen

Die Maschine verarbeitet Etiketten mit einer Mindestlänge von 12 mm und einer Höhe von 8 mm bis 70/90/120/150 mm. Der Rollendurchmesser beträgt üblicherweise 300 mm, der Kerndurchmesser 75 mm. Der Abstand zwischen den Etiketten liegt bei ca. 3 mm. Dank des integrierten automatischen Etikettenlängenerkennungssystems entfällt die manuelle Eingabe und Speicherung der Etikettenlängen sowie deren Abruf beim Wechsel der Etikettengröße und Neustart der Maschine. Dieses moderne System spart Kosten und wertvolle Zeit, vermeidet Maschinenstillstände und ermöglicht eine höhere Produktivität. Optional ist ein robustes Sicherheitsgehäuse aus Glas oder Acryl erhältlich. Die Maschine erfüllt alle grundlegenden Anforderungen an eine typische Druckmaschine auf dem heutigen Markt.