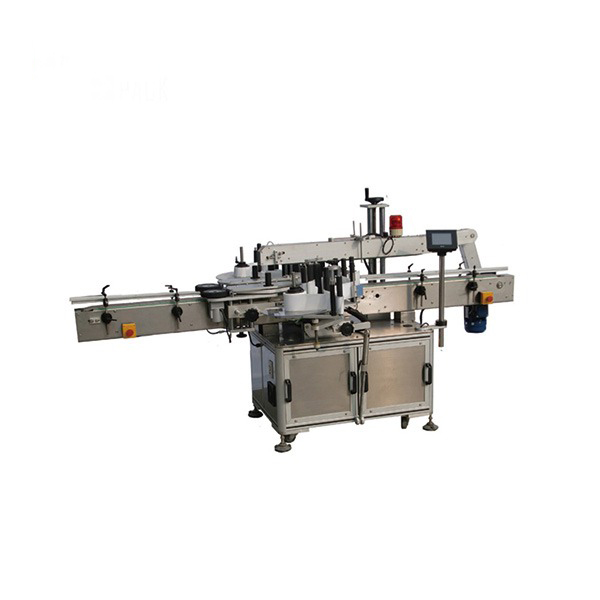

Etichettatrice automatica per bottiglie piatte

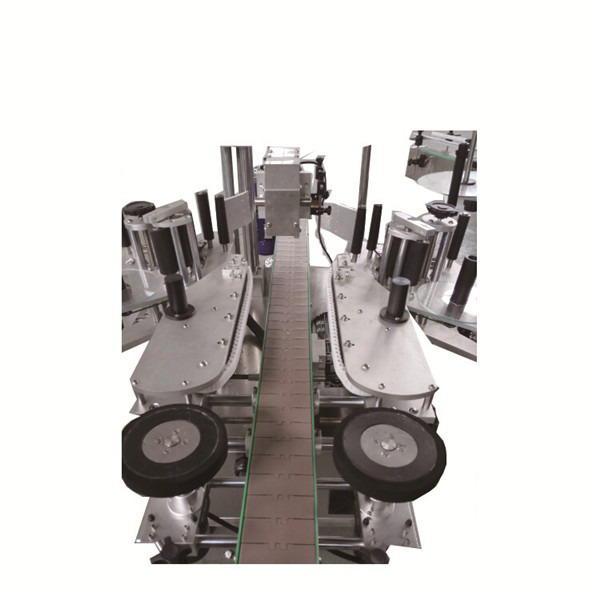

Questa etichettatrice automatica per bottiglie piatte può separare la bottiglia, un motore controlla il dispositivo di pressatura della bottiglia e il trasportatore, la bottiglia si muoverà linearmente sul trasportatore. Il servomotore, il PLC e il touch screen saranno ad alta definizione.

Questa etichettatrice automatica per bottiglie piatte può separare la bottiglia, un motore controlla il dispositivo di pressatura della bottiglia e il trasportatore, la bottiglia si muoverà linearmente sul trasportatore. Il servomotore, il PLC e il touch screen saranno ad alta definizione.

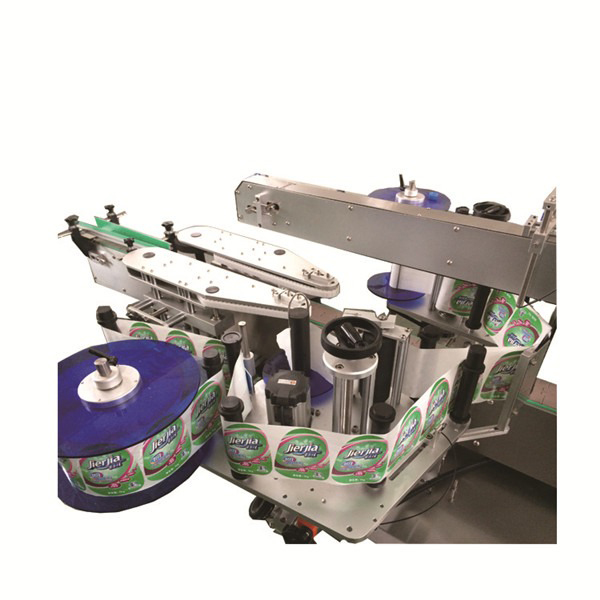

L'etichettatrice automatica per bottiglie piatte è progettata sulla base di due lati per bottiglie piatte e quadrate. Per soddisfare le esigenze di alcuni clienti che desiderano etichettare bottiglie a due lati e rotonde, è adatta per medicinali, prodotti chimici di uso quotidiano, forniture alimentari, elettronica e altro ancora. Questa macchina controlla un servomotore, un PLC e un touch screen, ed è un'etichettatrice multi-adesivo.

Descrizione

L'etichettatrice per etichette piatte viene utilizzata per etichettare un lato dei contenitori piatti; oppure per applicare etichette avvolgenti complete o parziali su contenitori di varie dimensioni. Questa macchina robusta presenta una finitura liscia in acciaio inox, che include anche il telaio principale. È l'apparecchiatura più intuitiva, con una capacità di etichettatura da 30 a 350 unità al minuto, a seconda delle dimensioni del prodotto e dell'etichetta. La velocità dipende anche dalla stabilità del contenitore sul nastro trasportatore della macchina a velocità più elevata. Questo modello sofisticato e semplice è dotato del più recente dispositivo di spaziatura del nastro che si traduce in un sistema senza sostituzione di componenti, anche in caso di modifica delle dimensioni dei contenitori e delle etichette. Inoltre, la macchina include un avanzato e distinto sistema di controllo a punto singolo per la variazione della velocità in linea. Infine, questa apparecchiatura versatile e precisa è rinomata per l'elevata precisione di posizionamento delle etichette. Incorpora anche un sistema di azionamento a frequenza CA integrato.

Tipo di imballaggio: Bottiglie

Materiale di imballaggio: metallo

Tipo: Etichettatrice, Etichettatrice

Condizione: Nuovo

Servizio post-vendita fornito: supporto online, supporto tecnico video, pezzi di ricambio gratuiti, installazione sul campo, messa in servizio e formazione

Luogo di origine: Shanghai, Cina

Nome del marchio: VKPAK

Tensione: 220V 50/60HZ

Applicazione: abbigliamento, bevande, prodotti chimici, alimenti, medicina

Peso: 200 kg

Grado automatico: automatico

Tipo di azionamento: meccanico

Dimensioni (L*W*H): 1800mm*1000mm*1300mm

Funzione: etichetta adesiva sulla bottiglia

Velocità di etichettatura: 20-100 bottiglie/min

Motore: servomotore

Nome macchina: macchina per l'applicazione di etichette

Materiale: acciaio inossidabile

garanzia: 1 anno

precisione di etichettatura: 1 mm

Servizio: supporto tecnico 24 ore su 24, 7 giorni su 7

imballaggio: cassa di legno per lunghe distanze

Parametro tecnico

| Nome | Etichettatrice automatica per bottiglie piatte |

| Velocità di etichettatura | 60-350 pezzi/min (a seconda della lunghezza dell'etichetta e dello spessore della bottiglia) |

| Altezza dell'oggetto | 30-350 mm |

| Spessore dell'oggetto | 20-120 mm |

| Altezza dell'etichetta | 15-140 mm |

| Lunghezza dell'etichetta | 25-300 mm |

| Diametro interno del rullo dell'etichetta | 76 millimetri |

| Diametro esterno del rullo dell'etichetta | 420mm |

| Precisione dell'etichettatura | ±1 mm |

| Alimentazione elettrica | 220V 50/60HZ 3,5KW Monofase |

| Consumo di gas della stampante | 5 kg/cm^2 |

| Dimensioni della macchina etichettatrice | 2800 (L) × 1650 (L) × 1500 (A) mm |

| Peso della macchina etichettatrice | 450 kg |

Caratteristiche principali:

- PLC e touch screen, servomotore

- Dotato di dispositivo di avviso di etichette insufficienti, etichette rotte

- Nessuna bottiglia, nessuna etichetta

- Nessuna etichetta, nessuna etichettatura e avviso automatico

- Nessun nastro, avviso automatico

- Controllo del servomotore, etichettatura stabile.

- Il sensore dell'etichetta e le parti elettriche sono realizzati in Giappone

- Adatto per bottiglie rotonde/piatte/quadrate

La macchina può utilizzare etichette con una lunghezza minima di 12 mm e un'altezza che varia da 8 mm a 70/90/120/150 mm. Solitamente il diametro del rotolo è di 300 mm e il diametro dell'anima è di 75 mm. La distanza tra le due etichette è di circa 3 mm. Inoltre, è dotata di un sistema integrato di rilevamento automatico della lunghezza delle etichette che elimina la necessità di inserire e memorizzare manualmente i dati della lunghezza delle etichette in memoria e di recuperarli al cambio del formato dell'etichetta e al riavvio della macchina. Questo moderno sistema consente di risparmiare sui costi complessivi, di risparmiare tempo prezioso, di evitare fermi macchina e di ottenere una maggiore produttività. Questo modello è disponibile con un robusto armadio di sicurezza opzionale in vetro o acrilico. Soddisfa tutte le esigenze di base di una macchina tipica richiesta dal mercato attuale.