Máquina de llenado por rebosamiento automático de baja viscosidad VK-OF

Cómo funciona:

El lado de suministro (azul oscuro) de una boquilla de dos piezas se utiliza para bombear el producto al contenedor. Cuando el contenedor alcanza la altura de llenado deseada, el exceso de producto y la espuma se expulsan (flechas rojas) a través del lado de retorno al tanque de origen del producto.

Solicitud:

Este tipo de llenadora es ideal para líquidos de viscosidad baja a media. También se pueden llenar líquidos con partículas sólidas que no superen 1/16″. Tenga en cuenta que las llenadoras de rebose son la máquina preferida para manipular productos muy espumosos a altas velocidades.

Ejemplos:

Salsas, jarabes, geles y champús ligeros, limpiadores espumosos y productos químicos, agua y otras bebidas acuosas no carbonatadas.

Ventajas:

Alto rendimiento, fácil de limpiar, fácil de operar, ampliable a bajo costo. Ofrece la mayor flexibilidad al menor costo.,

Detalles rápidos

La máquina llenadora automática accionada por servomotor VK-OF está especialmente diseñada y fabricada por VKPAK. Se aplica principalmente para llenar líquidos viscosos, como productos cosméticos, productos químicos de uso diario y también para productos alimenticios, como máquina llenadora de vinagre, máquina llenadora de desinfectante de manos.

Material de embalaje: Madera

Tipo: Máquina llenadora

Estado: Nuevo

Lugar de origen: Shanghái, China

Marca: VKPAK

Potencia: 2500W

Voltaje: 220 V, 50 Hz

Aplicación: Bebidas, productos químicos, alimentos, medicina

Peso: 400 kg

Calificación automática: Automática

Certificación: ISO9001 CE GMP

Tipo de accionamiento: Mecánico

Modelo: VK-OF

Nombre: Máquina automática de llenado de líquidos electrónicos

Función: Máquina llenadora de líquidos, taponadora y selladora.

Volumen de llenado: 100 ml-5000 ml

Control: PLC y pantalla táctil

Adecuado: líquido de baja viscosidad y alta espuma, vinagre, salsa de soja, vino blanco, desinfectante de manos, etc.

Garantía: 12 meses

Material: Acero inoxidable 304/316

Capacidad: 500-4000 botellas/h

Tipo de botella: plástico, botella de vidrio.

Servicio posventa: Ingenieros disponibles para dar servicio a la maquinaria en el extranjero.

La llenadora automática de rebose de baja viscosidad VK-OF es extremadamente flexible, especialmente para líquidos de baja viscosidad a alta densidad, como vinagre, salsa de soja, vino blanco, desinfectante de manos, etc. Se utiliza principalmente en las industrias química, alimentaria y farmacéutica.

Las piezas de repuesto se fabrican mediante máquinas CNC con acero inoxidable importado de alta calidad. Todos los componentes principales son importados de Japón, Alemania, Italia y Estados Unidos. Es totalmente automático, controlado por PLC y operado por pantalla táctil. Es fácil de usar y prácticamente no requiere mantenimiento.

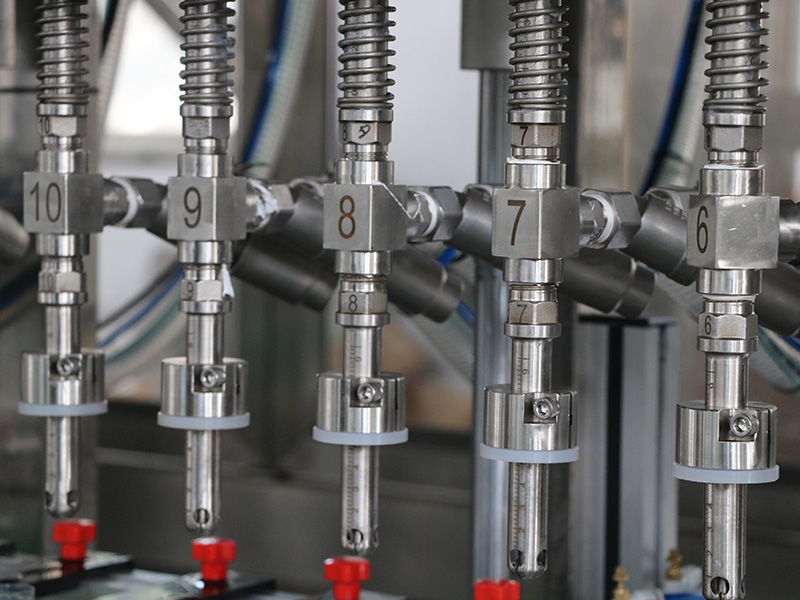

La fábrica de llenado automático por desbordamiento de baja viscosidad está fabricada con un marco de acero inoxidable 304 y es capaz de soportar de 2 a 16 boquillas de llenado Controles PLC, pantalla táctil.

| Nombre | Máquina de llenado por rebosamiento automático de baja viscosidad VK-OF |

| Modelo | VK-OF |

| Boquillas de llenado | 2-16 boquillas, o personalizadas |

| Fuerza | 0,75 kW-2,5 kW |

| Gama de botellas aplicadas | 30-100 ml, 100-1000 ml, 900-5000 ml |

| Precisión de llenado | ≤ ±0,5% |

| Velocidad de llenado | 500-4200 botellas/hora, 24b/min por 4 boquillas de llenado de 1L |

| Dimensión | 2200*1400*2300 mm |

| Peso | 400 kg |

| Fuente de alimentación | 220 V monofásico 50 Hz; 380 V trifásico 50 Hz |

Características principales

- Interfaz hombre-máquina en inglés, pantalla de contacto inteligente, diseño humano, fácil operación.

- Boquillas especiales de llenado por desbordamiento, llenado a nivel de precisión.

- Controlador lógico programable (PLC), fácil de cambiar de tamaño o modificar parámetros.

- Los elementos neumáticos son todos importados, estabilidad y confiabilidad.

- Detección fotoeléctrica y control de enlace neumático, protección automática por falta de botella.

- Diseño de posicionamiento cercano, fácil manejo, adecuado para empacar botellas de todos los tamaños.

- Toda la máquina está diseñada de acuerdo con los requisitos de GMP.

- La implementación de llenado con bomba, llenadores de desbordamiento para absorber espuma y eliminar el desbordamiento y goteo de espuma.

- Adopte una tolva de bajo líquido, conveniente para limpiar y desinfectar.

- Dispositivo de sujeción con índice de cuello, posicionamiento preciso de la boca de la botella antes de que las boquillas entren en las botellas.

- Fácil de ajustar el volumen, fácil de operar, cambia diferentes botellas en poco tiempo.

- Máquina diseñada y fabricada de acuerdo a la normativa GMP.

| Artículo. | Origen |

| Boquillas de llenado | VKPAK |

| Cinta transportadora | VKPAK |

| Motor del transportador | Taiwán YN |

| SOCIEDAD ANÓNIMA | Japón Mitsubishi |

| Pantalla táctil | Schneider |

| Contactor | Schneider francés |

| Interruptor automático | Schneider |

| Relé | Japón Omron |

| SMPS | Taiwán MW |

| Regulador de agua/aceite | Taiwán Airtac |

| Cilindro | Taiwán Airtac |

| Válvula solenoide piloto de puerto | Taiwán Airtac |

| Sensor fotográfico | Corea Autonics |

| Bomba centrífuga sanitaria | Origen chino |