Máquina taponadora automática de 6 ruedas con gatillo lineal

Las tapadoras VKPAK de 6 ruedas se utilizan para aplicar bombas de gatillo en producciones medias y altas, con un rango de velocidad que varía de 10 a 200 Bpm. Estas tapadoras de gatillo están diseñadas para aplicar bombas de gatillo, pero son extremadamente flexibles y versátiles, y admiten diferentes tipos de cierre. Además, son modulares, ya que pueden integrarse posteriormente con diferentes botellas y tapones nuevos.

Como todas las tapadoras VKPAK, estas tapadoras de gatillo son completamente personalizables según las necesidades del cliente: por ejemplo, la disposición del sistema de tapado se adapta a las instalaciones del cliente, la máquina puede funcionar en sentido horario o antihorario, y el alimentador de tapas puede colocarse al lado, delante o detrás de la máquina. Estas tapadoras son aptas para procesar diferentes tipos de envases, desde los más pequeños hasta los más grandes.

Descripción

- La máquina tapadora automática con gatillo lineal de 6 ruedas adopta el modo de un motor que controla una rueda tapadora, lo que puede garantizar que la máquina funcione de manera estable y mantenga un torque constante en condiciones de trabajo a largo plazo.

- Las correas de sujeción se pueden ajustar por separado, lo que permite que la máquina sea adecuada para tapar botellas con diferentes alturas y

formas - Si elige el sistema de guía de tapa opcional junto con la máquina, también se adaptará a las tapas de bomba.

- El cómodo sistema de ajuste de la construcción está equipado con una valiosa regla y contador.

- La máquina tapadora de botellas con husillo automático se puede levantar y bajar automáticamente mediante un motor.

Tipo de envase: Botellas

Material de embalaje: Madera

Tipo: Máquina taponadora

Estado: Nuevo

Servicio posventa: Repuestos gratuitos, instalación, puesta en marcha y capacitación en campo, mantenimiento y reparación en campo, soporte en línea, soporte técnico por video, ingenieros disponibles para dar servicio a la maquinaria en el extranjero.

Lugar de origen: China

Marca: VKPAK

Voltaje: 220 V, 50 Hz

Aplicación: Bebidas, productos químicos, productos básicos, alimentos, medicina, maquinaria y ferretería, prendas de vestir, textiles, máquina de tapado automático de rosca en la botella

Peso: 500 kg

Certificación: CE

Tipo de accionamiento: Eléctrico

Dimensiones (largo x ancho x alto): 1250 x 850 x 1750 mm

Sectores aplicables: Hoteles, tiendas de ropa, tiendas de materiales de construcción, plantas de fabricación, talleres de reparación de maquinaria, fábricas de alimentos y bebidas, granjas, restaurantes, uso doméstico, comercio minorista, tiendas de alimentación, imprentas, obras de construcción, energía y minería, tiendas de alimentos y bebidas, empresas de publicidad

Nombre: Máquina tapadora automática con pulverizador de gatillo

Modelo: VK-SC

Marca: VKPAK

Uso: para tapar o enroscar botellas

Función: tapado

Velocidad de tapado: 50-200 botellas/min (dependiendo de las botellas y la tapa)

Material: Acero inoxidable 304/316

Parámetro técnico

| Nombre Modelo | Máquina tapadora automática de husillo lineal VK-SC | |

| Capacidad | 0~200b/m (sujeto al tamaño de las botellas y la tapa) | |

| Diámetro de la botella y la tapa | Φ20~120 no es necesario cambiar ningún molde para diferentes tapas | |

| Altura de la botella | 40~460 mm | |

| Dimensión de la máquina | Largo 1060 x Ancho 896 x Alto 1620 mm | |

| Voltaje | CA 220 V 50 Hz | |

| Fuerza | 1500 W | |

| Peso | 500 kilos | |

| Sistema de alimentación de tapas | Elevador de gorras | Alimentador de tapas vibratorio |

| Dimensión | Largo 880 × Ancho 1000 × Alto 2600 mm | 800×600×1700 mm |

Imágenes de detalle

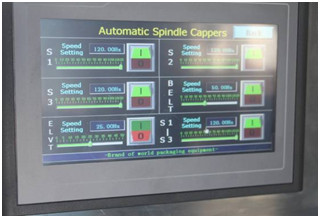

Pantalla táctil

Pantalla táctil

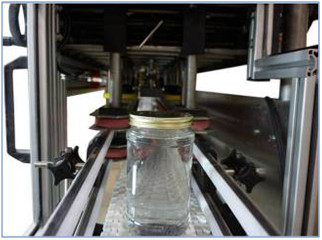

- 3 Pareja de ruedas para tapar

- Cada rueda es ajustable individualmente

- Las ruedas pueden girar en dirección opuesta para facilitar el ajuste de las tapas a las botellas si es necesario.

- La altura de dos correas es ajustable para adaptarse a diferentes tamaños de botellas.

- La rueda de tapado es suave para evitar que las tapas se dañen.

- La rueda de tapado se puede ajustar horizontalmente para diferentes tamaños de tapas.

- La rueda de tapado es ajustable verticalmente para botellas de diferentes alturas.

9 motores

6 motores para 6 ruedas de tapado

2 motores para correa de sujeción de botellas

1 motor para subir y bajar la máquina

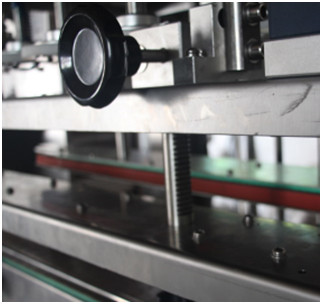

Índice del medidor para ajuste mecánico

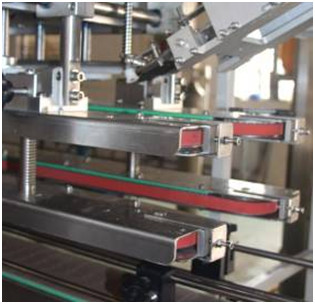

Correas de sujeción de dos niveles

Fácil ajuste entre cada nivel

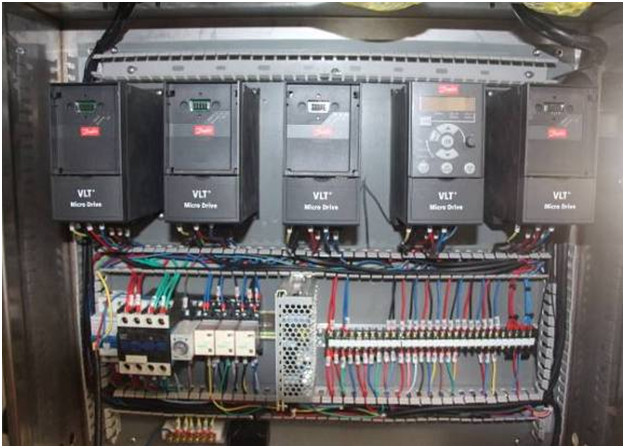

5 convertidores de frecuencia Danfoss

Relé Schneider

Características principales:

- ajuste de altura eléctrico

- Escape y conducto de tapa universales completos

- Operado por volante

- Ajuste de altura y anchura de la correa de sujeción

- Motores de CA de velocidad variable 4, 6 u 8

- Ruedas del husillo. Perillas de ajuste de la rueda del husillo, con volante de bloqueo.

- No se requieren piezas de cambio para una amplia gama de contenedores.

- Ejes de transmisión y ejes de soporte de ajuste de acero inoxidable sanitario 304

- Transmisión de potencia por correa de distribución para ruedas de husillo

- Cambio de tornillo inferior en ruedas de husillo

- Placas de montaje de aluminio de 1/2" y soportes anodizados de capa dura de 1/2" en la tolva de alimentación de tapas

- Diseñado para una fácil integración con la mayoría de las configuraciones de transportadores (se venden por separado)

- Intrínsecamente seguro

- Correas de doble agarre extraíbles

- Rieles para tapas de pulverización con gatillo

- Requisitos eléctricos especiales