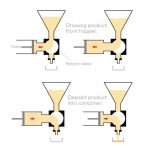

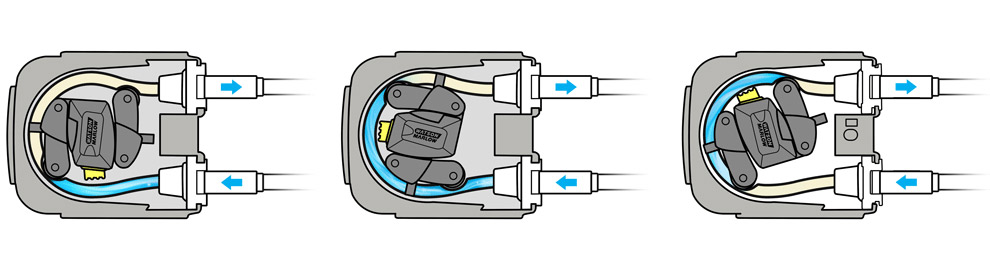

Una pompa peristaltica è un tipo di pompa volumetrica utilizzata per pompare una varietà di fluidi, comunemente nota anche come pompa a rulli. Il fluido è contenuto in un tubo flessibile inserito in un corpo pompa circolare (sebbene siano state realizzate pompe peristaltiche lineari). Un rotore con una serie di "rulli", "pattini", "raschiatori" o "lobi" fissati alla circonferenza esterna del rotore comprime il tubo flessibile. Quando il rotore gira, la parte del tubo sotto compressione viene pizzicata (o "occlusa"), costringendo così il fluido da pompare a muoversi attraverso il tubo. Inoltre, quando il tubo si apre al suo stato naturale dopo il passaggio della camma ("restituzione" o "resilienza"), il flusso di fluido viene indotto verso la pompa. Questo processo è chiamato peristalsi ed è utilizzato in molti sistemi biologici come il tratto gastrointestinale. Tipicamente, due o più rulli, o raschiatori, occludono il tubo, intrappolando tra loro una massa di fluido. La massa di fluido viene quindi trasportata, a pressione ambiente, verso l'uscita della pompa. Le pompe peristaltiche possono funzionare in modo continuo oppure possono essere indicizzate tramite rivoluzioni parziali per erogare quantità minori di fluido.Da Wiki]

Le pompe peristaltiche sono un tipo di pompa volumetrica utilizzata per pompare una varietà di fluidi. Il fluido è contenuto in un tubo flessibile o in un condotto inserito all'interno del corpo della pompa. Il principio di pompaggio vero e proprio, chiamato peristalsi, si basa sulla compressione e il rilassamento alternati del tubo flessibile o del condotto, che aspirano il contenuto e lo spingono lontano dalla pompa.

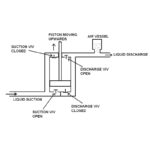

Un pattino o un rullo rotante scorre lungo il tubo flessibile o la tubazione, creando una tenuta temporanea tra il lato di aspirazione e quello di mandata della pompa. Quando il rotore della pompa gira, questa pressione di tenuta si sposta lungo il tubo flessibile o la tubazione, costringendo il prodotto ad allontanarsi dalla pompa e a riversarsi nella linea di mandata. Nel punto in cui la pressione è stata rilasciata, il tubo flessibile o la tubazione si riprende, creando un vuoto che aspira il prodotto nel lato di aspirazione della pompa, il meccanismo di adescamento.

La combinazione di questi principi di aspirazione e scarico dà luogo a una potente azione di spostamento positivo autoadescante.

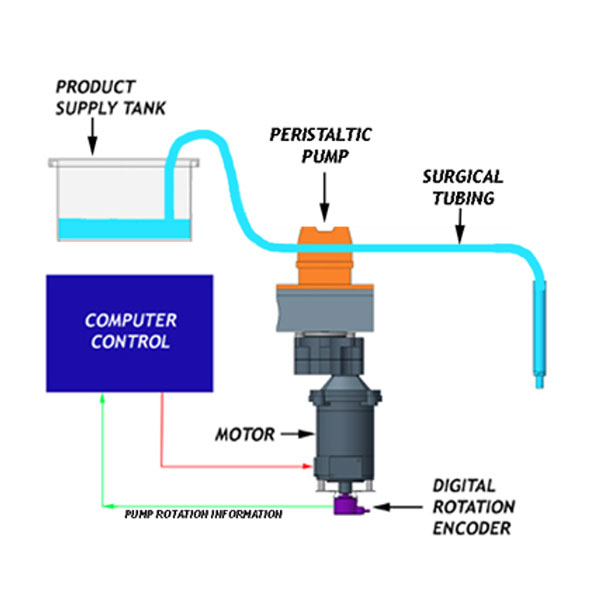

Principio della macchina riempitrice con pompa peristaltica

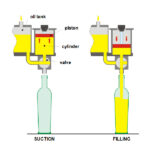

La pompa peristaltica effettua un contatto intermittente solo sulla parte esterna del tubo chirurgico (prodotto), in modo che il prodotto tocchi solo la parte interna del tubo. Il computer principale della riempitrice traccia in modo indipendente il numero di rotazioni della testa della pompa peristaltica (#) in modo da sapere con precisione la quantità di prodotto erogata. Una volta raggiunto il volume di riempimento desiderato, la pompa si arresta e il fluido rimanente non gocciola a causa dell'azione della pipetta. Il computer memorizza tutti i parametri di riempimento per cambi rapidi.

Applicazione:

Progettato specificamente per riempimenti di piccoli volumi di elevato valore con la massima precisione. Adatto per prodotti acquosi e altri prodotti a bassa viscosità.

Esempi:

Preparati farmaceutici, fragranze, oli essenziali, reagenti, inchiostri, coloranti e prodotti chimici speciali.

Vantaggi:

Il percorso del fluido è monouso; facile pulizia ed eliminazione dei problemi di contaminazione incrociata. Accuratezze di 0,51 TP3T sono ottenibili per volumi di riempimento inferiori a 1 ml.

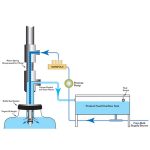

VKPAK automatico sistema di riempimento della pompa peristaltica è un sistema di riempimento da tavolo facile da usare. È adatto per piccoli volumi di prodotti a bassa viscosità. La sua facilità d'uso, la rapidità di cambio formato e l'assenza di rischi di contaminazione incrociata lo rendono un'opzione di riempimento ideale per preparazioni farmaceutiche, profumi, fragranze, reagenti, oli essenziali, inchiostri, coloranti, vernici diluite e vari altri prodotti chimici speciali. Questo sistema di riempimento automatico con pompa peristaltica può essere facilmente aggiornato fino a 24 canali per soddisfare eventuali esigenze di riempimento più elevate. Sono disponibili tubi di diversi materiali e dimensioni per adattarsi al prodotto specifico e al budget. È possibile utilizzare tubi molto economici e poi smaltirli, risparmiando tempo prezioso per la pulizia; inoltre, il sistema pompa la maggior parte dei prodotti direttamente dal serbatoio di stoccaggio, eliminando il trasferimento di prodotto da un serbatoio all'altro.

Riempimento: Bottiglia mediante oscillazione riordinare l'apribottiglie per posizionare il disco spesso, posizionando nuovamente il disco azionamento intermittente per riempimento, tappatura, coperchio, tappo a vite. Soluzione tramite pompa peristaltica aspirazione tramite tubo in silicone, nella stazione di riempimento, sempre tramite l'ago, che può essere spostato su e giù, riempiendo automaticamente il liquido nella bottiglia. L'ago si muove su e giù per completare il riempimento.

Tappatura: Aggiungere nuovamente un buon tappo all'interno della bottiglia posizionando il disco inviato all'affisso, avvitare il tappo, applicare un principio simile e urinare in linea di principio, viene eseguito dal cilindro, coprendo varie dimensioni tramite i COPERCHI a vite completi e costantemente rotanti sotto e complessivamente su e giù, quando la bottiglia si ferma correttamente, il declino della rotazione intrappola la finitura del coperchio a vite del coperchio. Il corpo del tappo a vite adotta il design della coppia costante, in base al tappo della bottiglia e alla filettatura della bottiglia con torsione, per regolare la fermezza del tappo a vite dopo il posizionamento può scorrere automaticamente, raggiungere l'obiettivo di non ferire la copertura delle bottiglie.