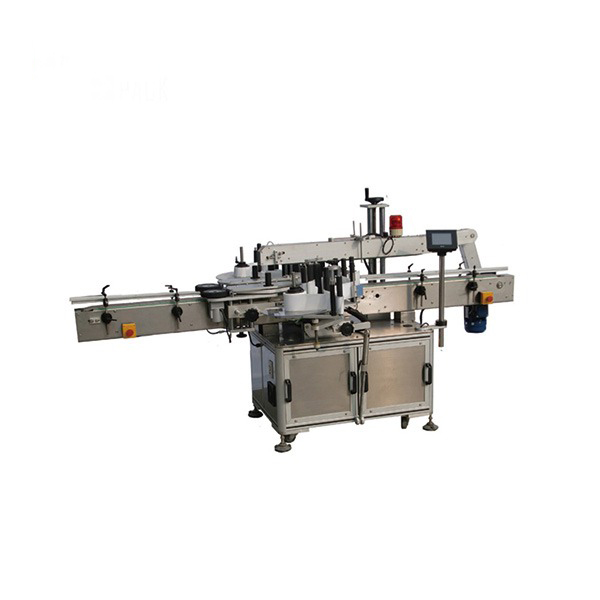

Automatisk merkingsmaskin for flate flasker

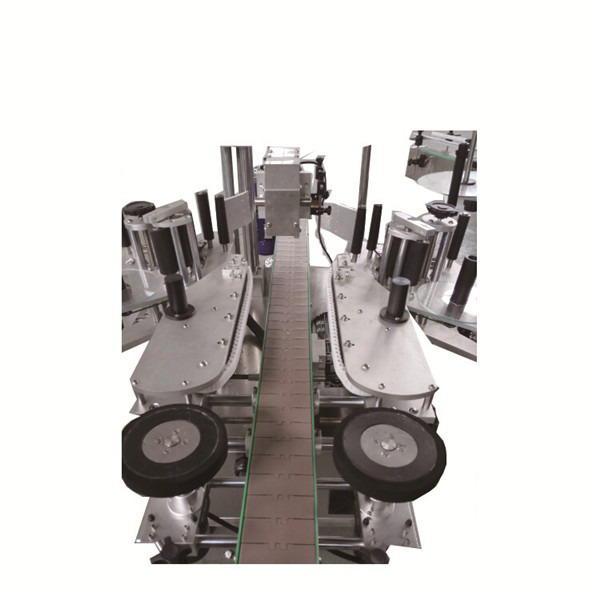

Denne automatiske merkingsmaskinen for flate flasker kan separere flasken. Én motordrift styrer pressflaskeenheten og transportbåndet, slik at flasken beveger seg lineært på transportbåndet. Servomotor, PLS og berøringsskjerm vil gi høy merking.

Denne automatiske merkingsmaskinen for flate flasker kan separere flasken. Én motordrift styrer pressflaskeenheten og transportbåndet, slik at flasken beveger seg lineært på transportbåndet. Servomotor, PLS og berøringsskjerm vil gi høy merking.

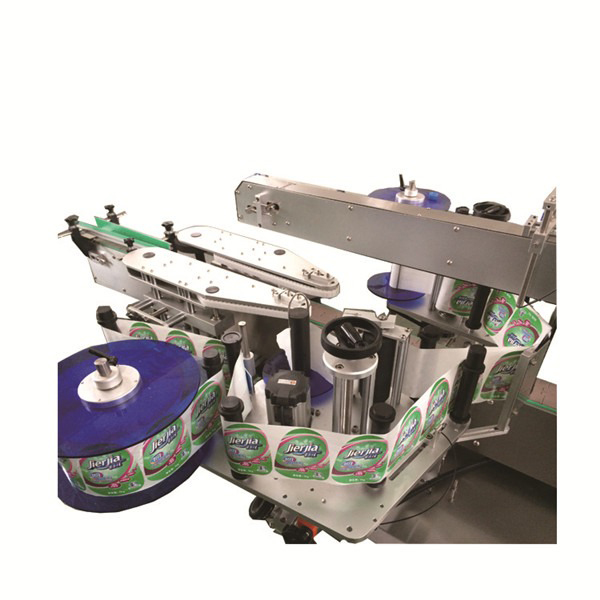

Automatisk merkingsmaskin for flate flasker er designet med to sider for flate flasker og firkantede flasker. For å møte noen av kundenes krav til merking av tosidige og runde flasker, er det medisin, daglig kjemikalier, matkulturartikler, elektronikk og så videre. Denne maskinen styrer servomotoren, PLS og berøringsskjerm, det er en merkemaskin for flere klistremerker/selvklebende etiketter.

Beskrivelse

Merkemaskinen for flate klistremerker brukes til å merke én side av flate beholdere, eller til å lage hel- og delvis omsluttende etiketter på ulike dimensjoner av andre beholdere. Denne robuste maskinen har en glatt rustfri ståloverflate, som også inkluderer hovedrammen. Det er det mest brukervennlige utstyret, med en kapasitet på merking fra 30 til 350 enheter per minutt, avhengig av størrelsen på produktet og etiketten. Hastigheten avhenger også av beholderens stabile bevegelse på maskinens transportbånd med høyere hastighet. Denne sofistikerte og enkle modellen har den nyeste belteavstandsenheten som resulterer i et system uten deler, selv om størrelsen på beholderne og etikettene endres. Dessuten inkluderer maskinen et avansert og distinkt ettpunkts kontrollsystem for online hastighetsvariasjon. Videre er dette allsidige og presise utstyret kjent for sin høye etikettplasseringsnøyaktighet. Det har også et integrert AC-frekvensdrivsystem.

Emballasjetype: Flasker

Emballasjemateriale: Metall

Type: Merkemaskin, Merkemaskin

Tilstand: Ny

Ettersalgsservice levert: Online support, videoteknisk support, gratis reservedeler, feltinstallasjon, igangkjøring og opplæring

Opprinnelsessted: Shanghai, Kina

Merkenavn: VKPAK

Spenning: 220V 50/60HZ

Søknad: Klær, drikkevarer, kjemikalier, mat, medisinsk

Vekt: 200 kg

Automatisk karakter: Automatisk

Drevet type: Mekanisk

Dimensjon (L * B * H): 1800 mm * 1000 mm * 1300 mm

Funksjon: klistremerke på flasken

Merkingshastighet: 20-100 flasker / min

Motor: servomotor

Maskinnavn: påføring av etikettmaskin

Materiale: Rustfritt stål

garanti: 1 år

merkingsnøyaktighet: 1 mm

Service: Teknisk støtte døgnet rundt

pakking: Treveske for langdistanse

Teknisk parameter

| Navn | Automatisk merkingsmaskin for flate flasker |

| Merkingshastighet | 60–350 stk/min (avhengig av etikettlengde og flasketykkelse) |

| Høyde på objektet | 30–350 mm |

| Tykkelsen på objektet | 20–120 mm |

| Høyde på etiketten | 15–140 mm |

| Lengde på etiketten | 25–300 mm |

| Etikettrullens innvendige diameter | 76 mm |

| Utvendig diameter på etikettrullen | 420 mm |

| Nøyaktighet av merking | ±1 mm |

| Strømforsyning | 220V 50/60HZ 3,5KW Enfase |

| Gassforbruk for skriver | 5 kg/cm² |

| Størrelse på merkemaskinen | 2800 (L) × 1650 (B) × 1500 (H) mm |

| Vekt av merkemaskin | 450 kg |

Hovedfunksjoner:

- PLS og berøringsskjerm, servomotor

- Utstyrt med varslingsenhet for utilstrekkelige etiketter, ødelagte etiketter

- Ingen flaske, ingen merking

- Ingen etiketter, ingen merking og automatisk advarsel

- Ingen bånd, automatisk advarsel

- Servomotorstyring, stabil merking.

- Etikettsensor og elektriske deler er produsert i Japan

- Passer til runde/flate/firkantede flasker

Maskinen kan bruke etiketter med en minimumslengde på 12 mm og en høyde som varierer fra 8 mm til 70/90/120/150 mm. Vanligvis er rulldiameteren 300 mm og kjernediameteren er 75 mm. Avstanden mellom de to etikettene er omtrent 3 mm. Videre har den et innebygd automatisk system for etikettlengdedeteksjon som eliminerer systemet med manuell mating og lagring av detaljer om etikettlengden i minnet, og henter de samme dataene når etikettstørrelsen endres og maskinen startes på nytt. Dette moderne systemet sparer totalkostnader, dyrebar tid, unngår maskinens nedetid og muliggjør høyere produktivitet. Denne modellen er tilgjengelig med et valgfritt robust sikkerhetsskap i glass eller akryl. Faktisk oppfyller den alle de grunnleggende behovene til den typiske maskinen som kreves i dagens marked.