Automatisk merkingsmaskin for orienteringsposisjon

VKPAK produserer klistremerkemaskin i Shanghai. Flaskeorientert merkemaskin er for den runde flasken og slipper bryet med manuell etikettering.

Kunden vil spare manuelle kostnader, og hastigheten vil bli enda høyere. Den brukes i farmasøytisk, kjemisk og næringsmiddelindustrien og så videre.

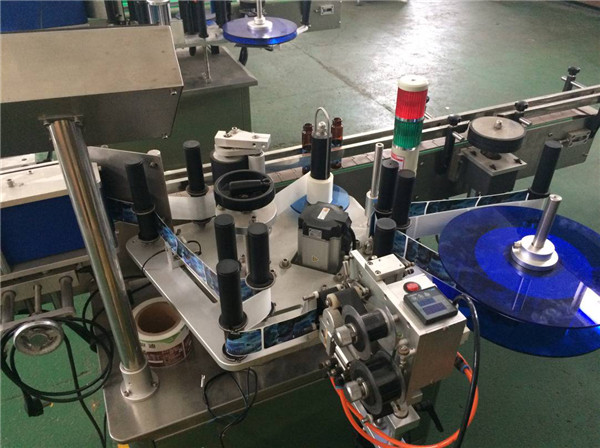

VKPAK er en profesjonell fabrikk innen alle typer merkemaskiner (klistremerkemerkingsmaskin , limmerkingsmaskin , maskin for merking av hylser) Flaskeorientert merkemaskin for sitcker er designet for klistremerkeetiketter/klebende etiketter, og fungerer for runde flasker, blikkbokser og krukker. Merkemaskin for klistremerker og flasker med automatisk lokalisering og konisk merking.

Beskrivelse

- Flaskeorientert merkemaskin styres av servomotor (nøyaktig etikett er 1 mm), den er egnet for alle typer runde beholdere. .

- Alle de elektriske delene av merkemaskinen er laget i Taiwan eller Japan

- Trepunkts holdemekanisme gir høy presisjon i merkingen av runde flasker

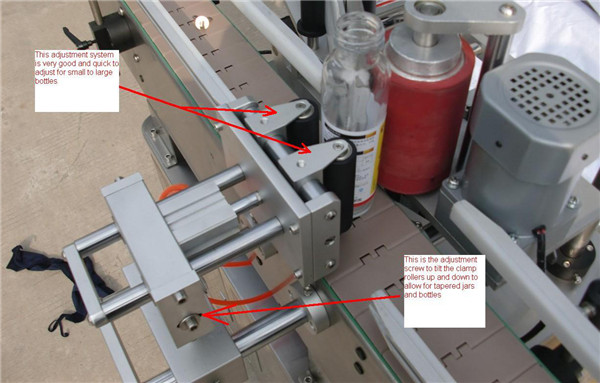

- Pneumatisk omviklingsstasjon for allsidig flaskediameter

Emballasjetype: Flasker

Emballasjemateriale: Tre

Type: Merkemaskin

Tilstand: Ny

Ettersalgsservice levert: Online support, Videoteknisk support, Gratis reservedeler, Feltinstallasjon, igangkjøring og opplæring, Feltvedlikehold og reparasjonstjeneste

Opprinnelsessted: Shanghai, Kina

Merkenavn: VKPAK

Spenning: 220v 50Hz

Søknad: Drikkevarer, kjemiske stoffer, matvarer, medisinske artikler

Vekt: 300 kg

Automatisk karakter: Automatisk

Sertifisering: ISO9000, CE

Dimensjon (L * B * H): 2000 mm * 850 mm * 1450 mm

Gjeldende bransjer: Hoteller, klesbutikker, byggevarebutikker, produksjonsanlegg, maskinverksteder, mat- og drikkefabrikker, gårder, restauranter, detaljhandel, matbutikker, trykkerier, byggearbeid, mat- og drikkebutikker, reklamebyråer

Navn: merkingsmaskin for orienteringsposisjon

modell: VK-RPL

Merkingshastighet (stk/min): 30–50 (avhengig av materiale og etikettstørrelse)

Merkingsnøyaktighet (mm): ±1,0 mm (materiale- og etikettstørrelser telles ikke med)

Etikettstørrelse (mm): (L) 20–300 mm (H) 30–180 mm

Materialstørrelse (mm): 20–120 mm (H) 40–200 mm

Innvendig rull (mm): 76 mm

Rullens ytre diameter (mm): Maks: 350 mm

Maskinstørrelse (mm): (L) 2000 * (B) 850 * (H) 1450 (mm)

Strømforsyning: AC220V 50Hz/60Hz 1500W

Teknisk parameter

| Navn | Flaskeorientert merkemaskin |

| Merkingshastighet | 20–40 stk/min (avhengig av etikettlengde og flasketykkelse) |

| Høyde på objektet | 30–200 mm |

| Tykkelsen på objektet | 30–90 mm |

| Høyde på etiketten | 15–140 mm |

| Lengde på etiketten | 25–300 mm |

| Etikettrullens innvendige diameter | 76 mm |

| Utvendig diameter på etikettrullen | 380 mm |

| Nøyaktighet av merking | ±0,5 mm |

| Strømforsyning | 220V 50/60HZ 0,8KW |

| Gassforbruk for skriver | 5 kg/cm² |

| Størrelse på merkemaskinen | 2000 (L) × 1000 (B) × 1250 (H) mm |

| Vekt av merkemaskin | 150 kg |

- Egnet for merking av runde flasker med fast punkt og posisjon.

- Bruk en differensialavstandsmekanisme for gummihjul, trinnløs hastighetsendring av omformeren, delt inn i valgfri avstand. Det er ikke nødvendig å endre spesifikasjonene til deler når du bytter produkter.

- Bruk importert velkjent merkevare servomotor, som sikrer høy hastighet, presisjon og stabilitet.

- Bruker sylinderposisjonering, rask handling og kan brukes for et bredt spekter av produktspesifikasjoner.

- Gummihjul som ruller på etiketter, lang levetid. Plasseringsmerking er merking med høy presisjon.

- Merkingsnøyaktighet ± 0,5 mm.

Konfigurasjonsdeler

| Konfigurasjon Deler av merkemaskin (VK-RPL) | |

| Beskrivelse | Bemerke |

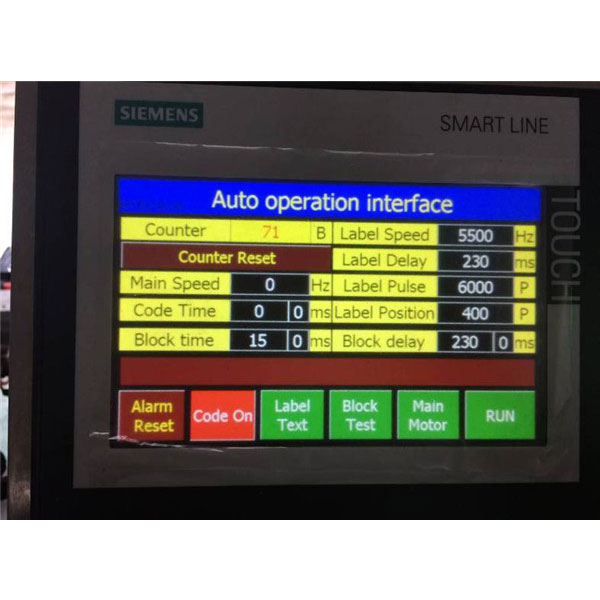

| PLS | Siemens |

| Berøringsskjerm | Siemens |

| Transduser | Delta laget i Taiwan |

| DC24V elektrisk kilde | Delta laget i Taiwan |

| Kontrollerer etikettsensoren | Keyence (laget i Japan) |

| Kontrollerer flaskesensoren | Keyence Laget i Japan |

| Optisk | Keyence Laget i Japan |

| PANASONIC MOTOR OG FØRER | Laget i Japan |

| BRYTER | SCHNIDER FRANKRIKE |

| Nødbryter | SCHNIDER FRANKRIKE |

Detaljbilder

Båndkodemaskin (skriv EXP PROD. BATCH på etiketten)

- 1. Et bredt bruksområde, for å dekke sylindermerkingens diameter på 10–100 mm

- 2. Merkingsnøyaktigheten er høy, og det lokale avviket fra ende til ende på taggen er ≤ ± 0,5 mm

- 3. Smart ekstruderingsenhetsmateriale, enkelt å sette arbeidsstykket på og automatisk fullføre merkingen

- 4. Justering av kortposisjon, enkel bryter for merking av forskjellige arbeidsstykker

- 5. Tannreimens trekkraft, noe som forbedrer den mekaniske stabiliteten betraktelig

Hovedfunksjoner:

- 1. Berøringsskjerm og PLS-kontroll

- 2. Rundt 30 minneoppskrifter for merkingsparametere som er enkle å endre flaskestørrelse.

- 3. Registrering av lav eller manglende etikett.

- 4. Synkronisert hastighetsvalg

- 5. Servomotordrift for høy nøyaktighet og høy hastighet

- 6. Ingen flaske, ingen merking.

- 7. Feste varmfolie-kodingsmaskin, som kan skrive ut EXP MFG BATCH på etiketten

Etiketteringsmaskiner er mye brukt i næringsmiddel-, farmasøytisk og daglig kjemisk industri for ulike etiketteringsapplikasjoner. VKPAK tilbyr orienteringsmerkemaskiner for runde, koniske og polygonale flasker med høy presisjonsorientering.