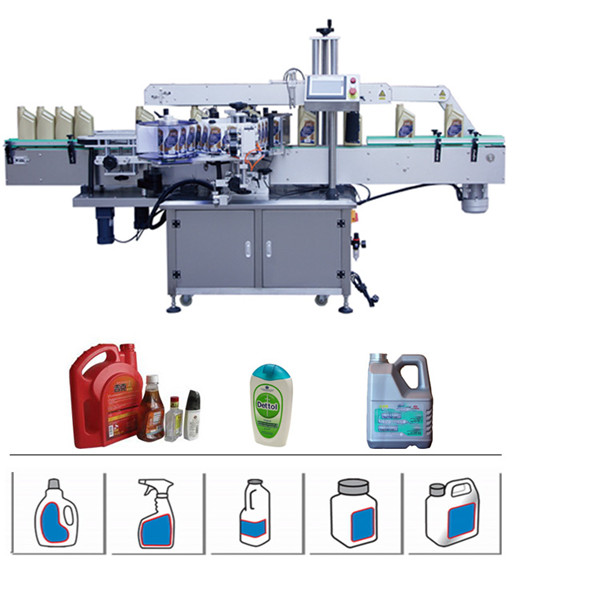

Automatisk selvklebende flaskemerkingsmaskin

Automatisk selvklebende flaskemerkingsmaskin er egnet for mange forskjellige typer flaskemerking. Ved merking vil flasken automatisk rotere slik at merkemaskinen kan legge trykk for merking.

Automatisk selvklebende flaskemerkingsmaskin er egnet for mange forskjellige typer flaskemerking. Ved merking vil flasken automatisk rotere slik at merkemaskinen kan legge trykk for merking.

Egnet for medisin-, næringsmiddel-, drikkevare- og kjemisk industri. Kan brukes til plast-, glass-, metall- og andre runde beholdere/flasker. Med sitt innovative design er betjeningen så enkel at selv en primitiv mann kan bruke den.

Beskrivelse

I bunn og grunn brukes en merkemaskin til å lime etiketter automatisk på produkter, beholdere, flasker osv. Manuell merking kan være en tidkrevende og uprofesjonell måte å pakke et produkt på. For lenge siden, da merkemaskiner ikke var oppfunnet, ble merkingen gjort manuelt på flasker, krukker, beholdere osv., noe som var en langvarig og tidkrevende prosess. Men nå har merkemaskiner blitt en velsignelse for industrien. Når det gjelder bulkpakking av produkter, finnes det ingen annen måte å merke produktene på enn å bruke en merkemaskin. Så merkemaskiner brukes i pakkeprosesser i mange industrier som legemidler, kosmetikk, dagligvarer, mat og drikke osv.

Emballasjetype: Flasker

Emballasjemateriale: Papir

Type: Merkemaskin, Merkemaskin

Tilstand: Ny

Ettersalgsservice: Online support, videoteknisk support, gratis reservedeler, feltinstallasjon, igangkjøring og opplæring, ingeniører tilgjengelig for å utføre service på maskiner i utlandet

Opprinnelsessted: Shanghai, Kina

Merkenavn: VKPAK

Spenning: 220V 50/60HZ

Søknad: Drikkevarer, kjemiske stoffer, matvarer, medisinske artikler

Automatisk karakter: Automatisk

Sertifisering: ISO9001

Drevet type: Mekanisk

Dimensjon (L * B * H): 1800 mm * 1000 mm * 1300 mm

Funksjon: klistremerke på flasken

Merkingshastighet: 20-100 flasker / min

Motor: servomotor

Materiale: Rustfritt stål

garanti: 1 år

merkingsnøyaktighet: 1 mm

Service: Teknisk støtte døgnet rundt

pakking: Treveske for langdistanse

Teknisk parameter

| Modell / tekniske parametere | VK-DSL |

| Merkingshastighet (stk/min) | 40–100 (avhengig av materiale og etikettstørrelse) |

| Merkingsnøyaktighet (mm) | ±1,0 mm (materiale- og etikettstørrelser telles ikke med) |

| Etikettstørrelse (mm) | (L) 20–280 mm (H) 30–144 mm |

| Materialstørrelse (mm) | Φ20–φ100 mm (H) 40–200 mm |

| Rull innvendig (mm) | φ76 mm |

| Rullens ytre diameter (mm) | Maks: Φ350mm |

| Maskinstørrelse (mm) | (L) 2000 * (B) 850 * (H) 1450 (mm) |

| Strømforsyning | AC220V 50Hz/60Hz 1500W |

- Stabil – Tilpasset Siemens PLC-kontroll og Panasonic servomotordrevet etikett for stabil maskindrift og etikettnøyaktighet. Den har høy ytelse og høy effektivitet.

- Enkel betjening – Berøringsskjermen kan være på engelsk, spansk, fransk, russisk og et hvilket som helst annet språk. Den er enkel å betjene og kan kobles til andre maskiner for produksjonspakkelinjen.

- Høy presisjon - Nøyaktighet fra +-0,5-1 mm. Bredt bruksområde - Brukes i stor grad med flaskediameter fra 25 mm til 120 mm, flaskehøyde 25 mm til 300 mm. Hvis tilpasset høyde på 10 mm-150 mm, lengde på 15 mm-300 mm, vennligst spør oss.

- Høy hastighet - Makshastigheten kan nå 150 flasker per minutt, avhengig av etikettstørrelse og flaskestørrelse.

- Europeisk standard - Merkemaskinen er laget i henhold til CE-standard, Taiwan-teknologi.

Detaljbilder

Arbeidsprosess for flaskemerkingsmaskin

- Sett flasker manuelt på transportbånd eller bruk en automatisk flaskedreieskive

Og flaskene vil bli separert med flaskeseparator for å holde avstanden mellom hver flaske og garantere arbeidsstabilitet. - Alle handlinger styres av PLS, automatisk registrering av flasken og etikettene, automatisk påføring av etiketter på begge sider av flaskene. Og maskin med funksjon, ingen flaske ingen merking, automatisk advarsel hvis ingen etikett eller mangel på etiketter

- Etter at etikettene er festet på flaskene, limer etikettlimeenheten etikettene for å feste etiketten på flaskene.

- Deretter går flasken til neste behandling

Hovedfunksjoner:

- Vedtar stepping servomotor, PLS-kontrollsystem, fargeberøringsskjerm.

- Bruk en japansk fotosensor for å oppdage og kontrollere lengden på etiketter automatisk.

- Utstyrt med varslingsenhet for utilstrekkelige etiketter, ødelagte etiketter og manglende kromatape.

- Nøyaktig etikettposisjonering, høy hastighet og høy merkingspresisjon.

- Automatisk deteksjon, ingen beholder ingen merking.

- Maskinhuset er laget av rustfritt stål, og oppfyller GMP-kravene fullstendig

- Den kan installeres med kode-/blekkskriver (valgfritt).

Den selvklebende etiketteringsmaskinen er helautomatisert, vertikal og lineær. Denne flerpakningsmodellen har en rekke brukervennlige funksjoner. Det er det mest passende utstyret for å påføre etiketter foran, bak eller på siden av flate, ovale, firkantede og runde beholdere. Denne robuste maskinen kan gi en maksimal produksjon på 100 etiketter på ett minutt, avhengig av produktenes form og størrelse, samt etikettstørrelsen. Den har også et automatisk og synkronisert system for å justere produktet med det øvre holdebåndsystemet. Et annet utmerket element i dette utstyret er det avanserte mikroprosessorstyrte etikettdispenseringssystemet, med det nyeste sensorsystemet for etiketter og produkter. Denne multifunksjonelle, høyhastighets etiketteringsmaskinen er effektiv, presis og holdbar. Den er bygget for å oppfylle de ulike kravene til brukerne i moderne pakkelinjer. Denne enkle å betjene og justere maskinen krever minimalt med verktøy og bytte av deler. Den kan spesialdesignes med en mateskrue og et lommesystem for å sikre riktig justering av flaskene på transportbåndet for nøyaktig merking. Denne modellen har til og med et eksklusivt synkronisert hastighetskontrollsystem med ett punkt. Videre gjør det innebygde og forhåndsinnstilte etikettlengdedeteksjonssystemet det mulig å unngå manuell mating og lagring av etikettlengdedata i minnet, og hente dem hver gang du skal endre etikettstørrelsen og starte utstyret på nytt. Dermed sparer du tid, forhindrer maskinens nedetid og forbedrer produktiviteten. Det er også tilgjengelig med et valgfritt sikkerhetsskap laget av slitesterkt glass eller akryl. Dette utstyret kan spesialdesignes for å påføre ensidige etiketter på flate flasker og flaskehus, og pakke runde etiketter inn på runde flasker. Dessuten inkluderer det alle de essensielle egenskapene til en standardmodell i henhold til dagens marked.