자동 피스톤 점성 액체 충전기

애플리케이션:

이 유형의 피스톤 필러는 페이스트, 반 페이스트 또는 큰 입자가 포함된 덩어리 형태의 점성 제품에 가장 적합합니다. 이 피스톤 필러는 식품 등급 기준을 충족하도록 제작되었으며 다양한 화학 용도에도 적합합니다.

예:

진한 소스, 살사 소스, 샐러드 드레싱, 화장품 크림, 진한 샴푸, 젤, 컨디셔너, 페이스트 클리너 및 왁스, 접착제, 진한 오일 및 윤활제.

장점:

이 저렴한 기존 기술은 대부분의 사용자가 쉽게 이해할 수 있습니다. 상당히 두꺼운 제품도 빠른 충전 속도를 얻을 수 있습니다. 주의: 이 기술은 서보 용적식 필러의 등장으로 거의 사용되지 않습니다.

설명

이 충진기는 다양한 점도의 유체를 충진하는 데 적합한 피스톤식 충진기입니다. 인라인 구조로 제작되었으며, 충진 헤드 개수는 6/8/10/12/16/20개 등 생산 용량에 따라 맞춤 제작 가능합니다.

충전 시스템은 서보 모터로 구동되어 높은 충전 정확도를 보장하며, 터치 스크린에서 직접 충전량을 쉽게 설정할 수 있습니다.

화장품, 식품, 특수화학, 제약, 개인 관리 산업에서 널리 사용됩니다.

VK-PF 자동 서보 모터 구동 피스톤 충전기는 VKPAK에서 특별히 설계 및 제조한 제품으로, 주로 화장품, 일용 화학 제품과 같은 점성 액체를 채우는 데 적용되며, 꿀 충전기, 소스 충전기와 같은 식품에도 적용됩니다.

포장 유형: 병

포장재 : 목재

유형: 충전기

상태: 새것

제공되는 애프터 서비스: 온라인 지원, 비디오 기술 지원, 무료 예비 부품, 현장 설치, 시운전 및 교육

원산지: 중국 상하이

브랜드 이름: VKPAK 저렴한 피스톤 자동 소스 충전기

전압: 220V/380V

응용 분야: 식품

무게: 1200kg

자동 등급: 자동

구동 방식: 전기

치수(L*W*H): 2500*1400*2500mm

이름: 소스용 저렴한 피스톤 자동 충전기

접점 재질: 316SS

제어 : 서보 모터 제어 충전량

처리 유형: 액체를 병에 채우기

충전량 : 1000ml~5000ml, 100ml~1000ml

기계명 : 소스 자동충전기

소재: 스테인리스 스틸

용량: 800-4200BPH

충전 정확도: 0.2%

다양한 유형의 VKPAK 자동 피스톤 충전기

소스 충전기는 용량에 따라 많은 모델과 유형이 있으며, 충전 노즐 수는 헤드 1개에서 헤드 16개까지 있고, 충전 용량은 100g에서 1000g까지입니다.

자동 피스톤 필러의 주요 구조

- 옵션으로 20L~200L 상단 호퍼, 옵션으로 가열 및 혼합 시스템이 있는 이중 재킷 호퍼,

- 304SS로 제작된 기계 본체

- 노즐 채우기, 노즐 채우기는 특별히 소스가 떨어지지 않도록 설계되었습니다.

- 공기 실린더에 의해 위아래로 움직이는 노즐 채우기, 옵션으로 서보 모터가 위아래로 움직이는 충전

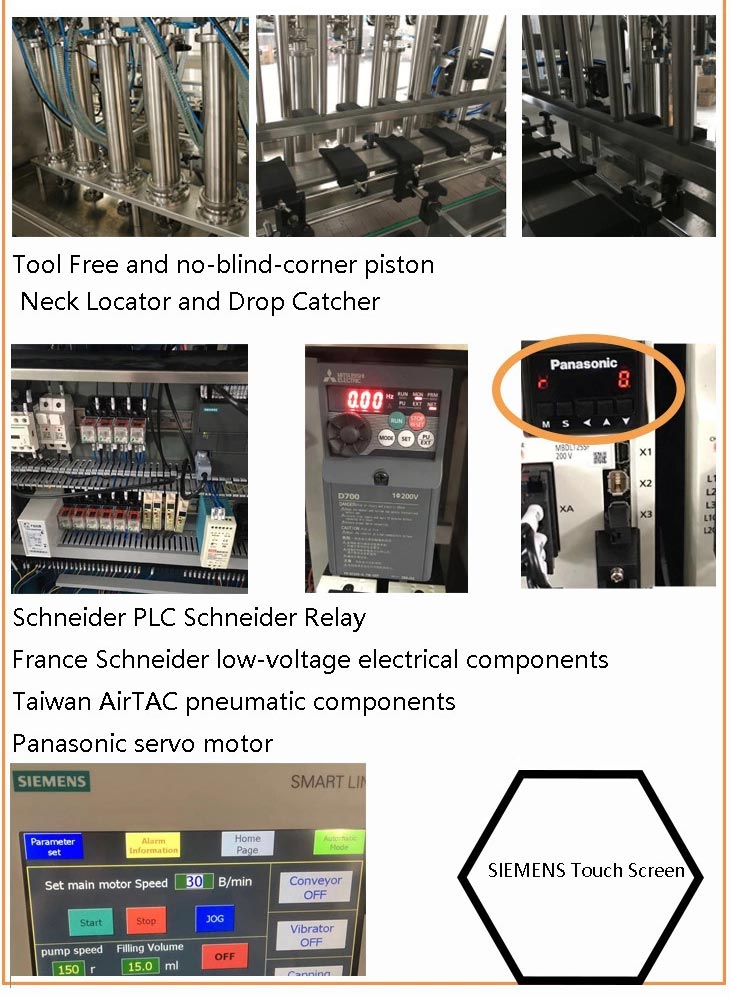

- PLC 제어 시스템 및 HMI 작동

- 특별히 제작된 말과 꿀용 밸브, CIP 시스템으로 말을 연결합니다.

자동 피스톤 필러의 경쟁 우위

자동 피스톤 충전기에는 많은 장점이 있습니다

- PLC 제어, 터치스크린 조작.

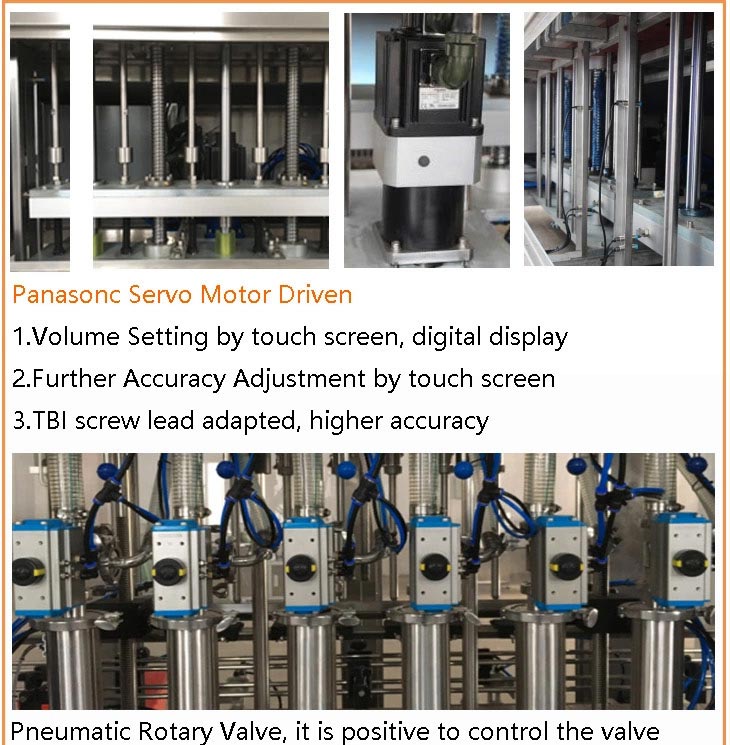

- 파나소닉 서보 모터 구동 방식으로 HMI에서 자동으로 충전량을 조절합니다. 예를 들어, 사용자가 500g의 소스를 채우고 싶다면 숫자 500만 입력하면 기계가 자동으로 충전량을 조절합니다.

- 피스톤 방식으로 체적 충전이 가능하며 충전 정확도가 높습니다.

- 상단에 이중 재킷 가열 및 혼합 탱크가 있습니다.

- 자동 소스 충전기는 사용자의 CIP 시스템을 연결하는 CIP 시스템 기능도 갖출 수 있습니다.

- 소스 필러의 말은 소스의 특성에 따라 특별히 만들어졌으며, 사각지대가 없고 식품 등급입니다.

- 소스 필러의 부드러운 튜브나 파이프는 일본의 세계적인 브랜드인 Toyox에서 만든 것입니다.

- 점성이 있는 소스의 이송을 위해 특별히 제작된 회전 밸브입니다.

기술적 매개변수

| 노즐 채우기 | 1-16노즐 |

| 생산 능력 | 시간당 800-5000병 |

| 볼륨 채우기 | 100-500ml, 100ml ~ 1000ml |

| 힘 | 2000W, 220VAC |

| 정확성 | ±0.1% |

| 주도하다 | 파나소닉 서보 모터 |

| 인터페이스 | 슈나이더 터치스크린 |

채울 제품:

1) 고온 충진(35~40℃), 저온 충진 상온

2) 비중 : 1.1 ~1.4 gr/cm3

3) 초콜릿 페이스트 바르기 • 꿀 • 치즈 페이스트, 당밀 바르기.

병 유형:

1) PET병 • 사분면 단면 • 용량 250ml • 목 32mm.

2) 유리병 & PE, PET병 • 원통형 단면 • 용량 200 ~ 350ml • 목 45mm.

충전 허용 오차: +/- 최대 0.5%

세부 이미지

주요 특징:

- 충전량 조절이 쉽고, 터치스크린으로 자동 조절되며, 정확도가 높고 속도가 안정적입니다.

- 선형형 충전 시스템은 다양한 유형의 병에 맞게 쉽게 조정할 수 있습니다.

- 유지관리가 쉽고, 특별한 도구가 필요하지 않습니다.

- 병 없음, 채우기 없음, 자동 PLC 제어

- 막힌 충전 노즐은 안티 드롭, 실크 및 자동 절단 점성 액체입니다.

- ±0.5-1% 이내의 정확한 충전 용량과 전체 병 카운터.

- 액체가 부식성인 경우 특수 씰이나 호스를 사용합니다.

- 필요한 경우 발포 제품의 바닥 위로 채우기 위한 다이빙 노즐

- 병 입구를 찾을 수 있습니다

VKPAK 자동 피스톤 필러는 모든 점성 액체를 정확하고 빠르게 충전할 수 있는 매우 유연한 필러입니다. 벌크 탱크에서 피스톤으로의 제품 이송은 레벨 감지 플로트를 사용하는 버퍼 탱크, 직접 배출 방식의 매니폴드 또는 재순환 방식을 통해 구성될 수 있습니다. VKPAK 자동 피스톤 필러는 304 스테인리스 스틸 프레임으로 제작되었으며 1개에서 16개의 충전 헤드를 지원할 수 있습니다. PLC 제어, 터치스크린 HMI, 식품 등급 접촉 부품, 스테인리스 스틸 및 양극 산화 처리 알루미늄 구조 등 다양한 기능이 기본으로 제공됩니다. VKPAK 자동 피스톤 필러는 화장품, 식품 서비스, 특수 화학, 제약 및 개인 관리 산업에서 사용되는 모든 생산 라인의 효율성을 높이도록 설계되었습니다. 위생, 위험, 인화성 및 부식성 환경에 적합한 추가 옵션도 제공됩니다.

최대의 효율성과 쉬운 유지관리를 제공하도록 설계된 VKPAK은 직관적인 엔지니어링, 저렴한 가격, 다용성, 효과성을 바탕으로 액체 포장 시스템을 위한 최고 품질의 피스톤 충전기를 제공합니다.

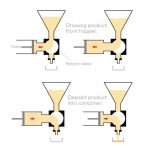

VKPAK의 피스톤 충진기는 다양한 제품에 체적 충진 원리를 사용합니다. 반자동 및 자동 피스톤 충진기 모두 피스톤이 뒤로 당겨져 공급 시스템에서 일정량의 제품이 실린더로 들어갑니다. 그런 다음 피스톤이 실린더로 돌아오면서 제품은 노즐에서 밀려나 대기 중인 용기로 들어갑니다.

피스톤 충전기는 광범위한 점도를 처리할 수 있지만, 가장 높은 점도의 제품과 입자가 큰 제품에 적합한 경우가 많습니다.

다양한 고품질 제품을 통해 고객은 최고의 호환성, 내구성, 그리고 유연성을 기대할 수 있습니다. 이 기계들은 생산 라인의 효율성을 높이도록 설계되었습니다.

오늘 저희에게 연락해 솔루션을 찾아보세요!