Automatic Ampoule/Vial Bottle Labeling Machine

Ampoule/vial bottle labeling machine is mostly applicable for small diameter round containers for medicine, ampoule, vial, oral liquid, blood tube, pen.

The VK-HRL High speed horizontal labeling machine is applicable for labeling for small diameters of containers, such as ampoules bottles, super glue bottles, batteries and so on.

- 304 Stainless steel frame construction

- Labeling speed is automatically synchronized with conveyor speed to ensure quality labeling;

- Automatic infeed turntable diameter 550mm

- Hot foil coding machine

- Servo motor and PLC and Touch Screen assure prefect label exact

Description

The Automatic Ampoule/Vial Bottle Labeling Machine is fabricated under rigid supervision, keeping in view the strict GMP standards for use in Pharmaceutical and allied industries. Very strict quality control standards adopted during the manufacturing process ensure trouble free operation and need minimum maintenance / shutdown time. The High out put of the machine saving production cost and also saves valuable time. The Automatic Ampoule Labeling Machine has Variable AC Frequency Drive system for smooth control of the machine for required out-put Upto 300 Ampoules per minute. The machines having online batch printing. The Super Silent Machine has minimum noise pollution and thus result in increased productivity amongst the work force. Inclined in-feed hopper ensures uniform flow of objects for labeling.

Packaging Material: Metal

Type: Labeling Machine

Condition: New

Place of Origin: Shanghai, China

Brand Name: VKPAK

Model Number: VK-HRL

Power: 2.4KW

Voltage: 220V/360V

Application: Medical

Weight: 340KG

Automatic Grade: Automatic

Certification: CE Certificate

Driven Type: Electric

Name: VK-HRL ampoules/sausage labelling machine

Product name: ampoules/sausage labelling machine

Usage: Adhesive Labels Bottles

Function: Auto Sticker Labeling Equipment

Labeling speed: 300b/m

Material: 304/316 Stainless Steel

Model: VK-HRL

Advantage: Economy Labeling Machine

Other name: Horizontal labeling machine

Bottle type: Horizontal bottle

After-sales Service Provided: Engineers available to service machinery overseas

The vial sticker labeling machine is completely automatic and can be operated at extremely high speeds. Moreover this model is very user friendly, and also has several other outstanding features. In fact, it is built using the most modern micro processor controlled label dispensing system. The vial labeling machine also includes the latest sensing system for labels, and many other products. It is therefore regarded as the ideal machine for labeling round vials, small sized bottles, and several other round objects; which are made from glass, plastic, PET, HDPE, PP, etc.

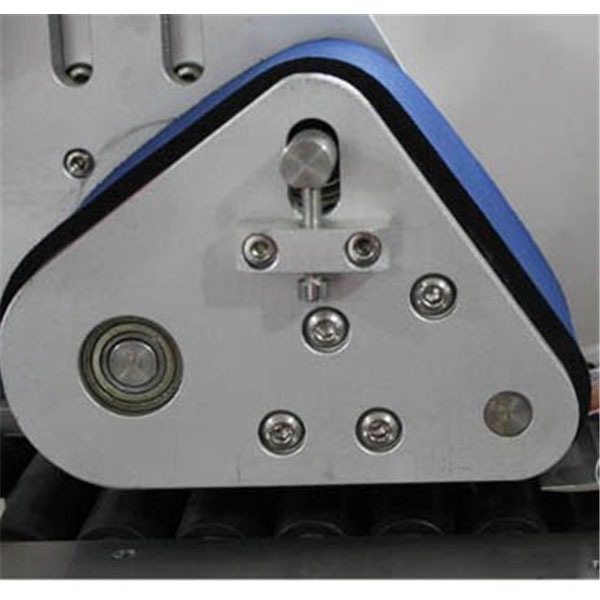

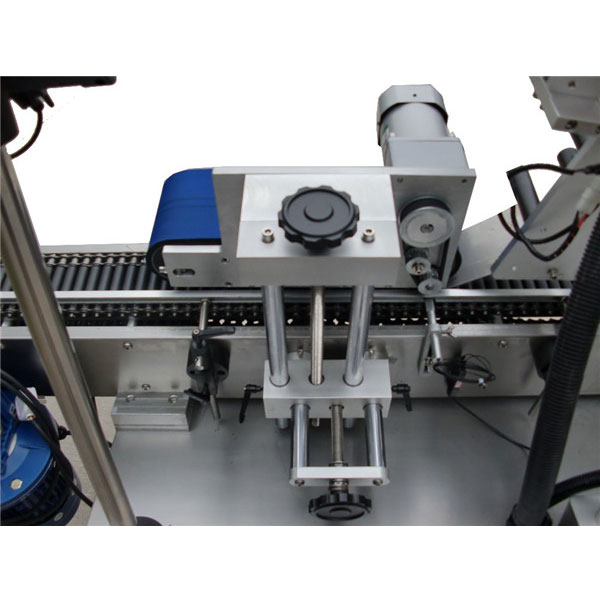

This swift and sturdy equipment has the ability to label at the most 300 units in a single minute; based on the diameter of the product and size of the label. Further, the roller spacing device of this totally automatic vial sticker labeling machine, results in a simple no parts change system. In addition to this, it also helps you to do away with the star wheel or feed worm for evenly separating the products. Besides this vial labeler machine even incorporates an exceptional, single point synchronized speed control system. Moreover, it also has a programmed label length detecting system.

This built-in mechanism thus helps to avoid the manual feeding and storing of the label length data into the memory; and again retrieving that information every time, when you want to change the label size and restart the vial labelling machine. As a result this automated system helps to save your time by preventing machine downtime, and also increases the efficiency. These vial labeling machines are even available with an optional tough glass, or acrylic safety cabinet. This advanced vial labelling equipment actually includes all the basic features that are required in a standard machine, to meet the diverse needs of the customers in the local and global market.

Technical Parameter

| Name | Ampoule/Vial Labeling Machine |

| Drive | Servo Motor Driver |

| Labeling Speed | 100-300PCS/Min |

| Bottle Diameter | 10mm-30mm |

| Label Length | 15mm-150mm |

| Label Height | 10mm-90mm |

| Label Exact | 1mm |

| Max Label Roll Diameter | 300mm |

| Label Core Diameter | 76mm |

| Dimension | 1800mm*800mm*1600mm |

| Power | 220V Single Phase 750W |

Automatic Ampoule Sticker Labelling Machine for self adhesive sticker application onto ampoules. The ampoule labeler is one of the most users friendly ampoule labelling machine. The Machine incorporates with modern Micro Processor Control Label Dispensing system with user friendly Sensing system for Label and Product. The machine is suitable for Labeling on Round Vials, and other round Objects. It is capable of Labelling up to 300 units per minute depending on products and label size. Specially designed electronic and mechanical system to apply transparent (No Look) Labels on Vials at very high speed using optional special label sensing system.

The Inbuilt Automated Label Length detection systems eliminates any need for manually feeding and storing of Label Length data in memory and retrieving the same every time for change of Label Size & re-starting the machine. The System thus saves valuable time, avoiding machine-down time, and helps achieve higher production.

Machine have added advantages like Special Feeding Device enabling feeding of Ampoules/Vials in Vertical Position directly from the trays and similarly collecting the labeled products also in Vertical Position in trays. Operator can also feed the Ampoules/Vials for Labeling On-line on Machine without any stoppage. The feeding system effectively eliminates clumsy, inconvenient, time consuming and prone to breaking of Ampoules etc. at the time of loading the products for labeling compare to other slant hopper Feeding system.

Machine also available with optional Turn Table for Feeding of Vials for online transfer of Ampoules from Capping/Inspection machine to labeling and online transfer of labeled vial to packing conveyor/inspection system, this system helps for continues labeling operation for vials.

Main Features:

- Automatically check the length of labels

- Equipped with warning device of insufficient labels, broken labels

- No bottle, no labeling

- No labels , no labeling and automatic warning

- No Ribbon, automatic warning

- The bottle stand on the tray , and automatic lay down on conveyor for labeling

- Servo motor control label , no label break , high speed.

The ampoule sticker labeling machine delivers a labeling accuracy of less than 1mm. It has an incorporated logic control unit used to store and retrieve production data on the machine. Ampoule labeller is equipped with servo motors sourced from renowned manufacturers around the world. The sticker labeling machine for ampoules can deliver up to 300 labels per minute. It is also firm and robust in construction to eliminate any vibration and enhance accuracy during operation.

With this model of the machine, there is no down time occurring when changing between labels of different sizes. There speeds of the conveyor, label dispenser, and the pressing device are well synchronized for efficient operation. The machine is also maintenance free and easy to adjust the dimensions as per the different label sizes in process.

The ampoule labeling machine has lessened the stress of labelling an ampoule via the manual method. The ampoule labelling machine is fully automatic and can operate at high speed thus reducing the time consumption. The ampoule sticker labeling machine is quite easy to use and it is used for labeling ampoules at a fast pace.

This labeling machines consist of label dispensing system which is backed by the latest and advanced microprocessor. It also holds advanced sensing systems for labels and products. This advanced technology based labeling machine is capable to attach varying units per minutes. The machine is made of stainless body and is compact in size.